Featured products

Desiccant dehumidifiers

Robust, effective and economical – discover desiccant dehumidifiers that prevent corrosion in your compressed air systems with unwavering reliability.

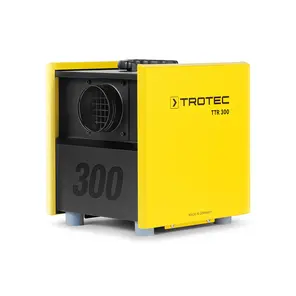

Trotec TTR 300 – desiccant dehumidifier

The TTR 300 is a high-performance desiccant dehumidifier designed to tackle excessive moisture in industrial and commercial environments. Known for its user-friendly interface, intuitive controls and portable design for flexible placement.

Also suitable for:

- Vehicle environmental simulation

- Vehicle assembly lines

- Automotive parts warehouses