Why humidity is a major challenge for pharmaceutical production

- Home

- Insights

- Humidity control and drying insights

- Why humidity is a major challenge for pharmaceutical production

Industrial dehumidifiers have a wide range of applications in environments where it is essential to maintain exact temperature and relative humidity (RH) levels. In this article, we explore the role that dehumidifiers play behind the scenes in the pharmaceutical industry to reduce costs, maximise yield and ensure product safety.

Keeping pharmaceutical production on track

Precise environmental control is key in keeping up with the advancements in manufacturing techniques that are driving the pharmaceutical industry forward. This can be the defining factor that gets your product to market before your competitors’.

The humidity levels inside your production facilities will affect the outcome at every stage of the process – from research and development, to manufacturing, packaging and storage. For example, when RH levels are too high, there is a risk that products will absorb the moisture in the air which can make them less effective and, in some cases, dangerous as a result. This is a particular problem in the production of antibiotics as it can lead to a reduction in potency.

Water absorption due to high RH levels

Reduces potency and effectiveness of products

Can cause products to become toxic

Leads to the growth of bacteria, viruses, mold, fungi and mites

Can lead to clogging of machinery during production

To help ensure public safety in the production of potentially life-saving drugs, The World Health Organisation (WHO) recommends maintaining RH levels at 50% to optimise quality, yield and shelf-life.

Unregulated humidity has all kinds of implications in bringing a product to market as well as its long-term stability and effectiveness as a drug. Faults in environmental control are one of the biggest reasons for the rejection of entire batches of products. Not only does this come at a huge cost financially, it could also put you weeks, or even months, behind competitors in the development and roll-out of new products.

Beyond the manufacturing process, it’s also crucial for temperature and humidity levels to be optimised for storage. The exact conditions should be defined by the product, but this is normally at 50% RH and between 15°C and 25°C for drugs kept at room temperature.

When the difference in a few degrees can result in the loss of so much hard work and risk public safety, accurate climate control is vital.

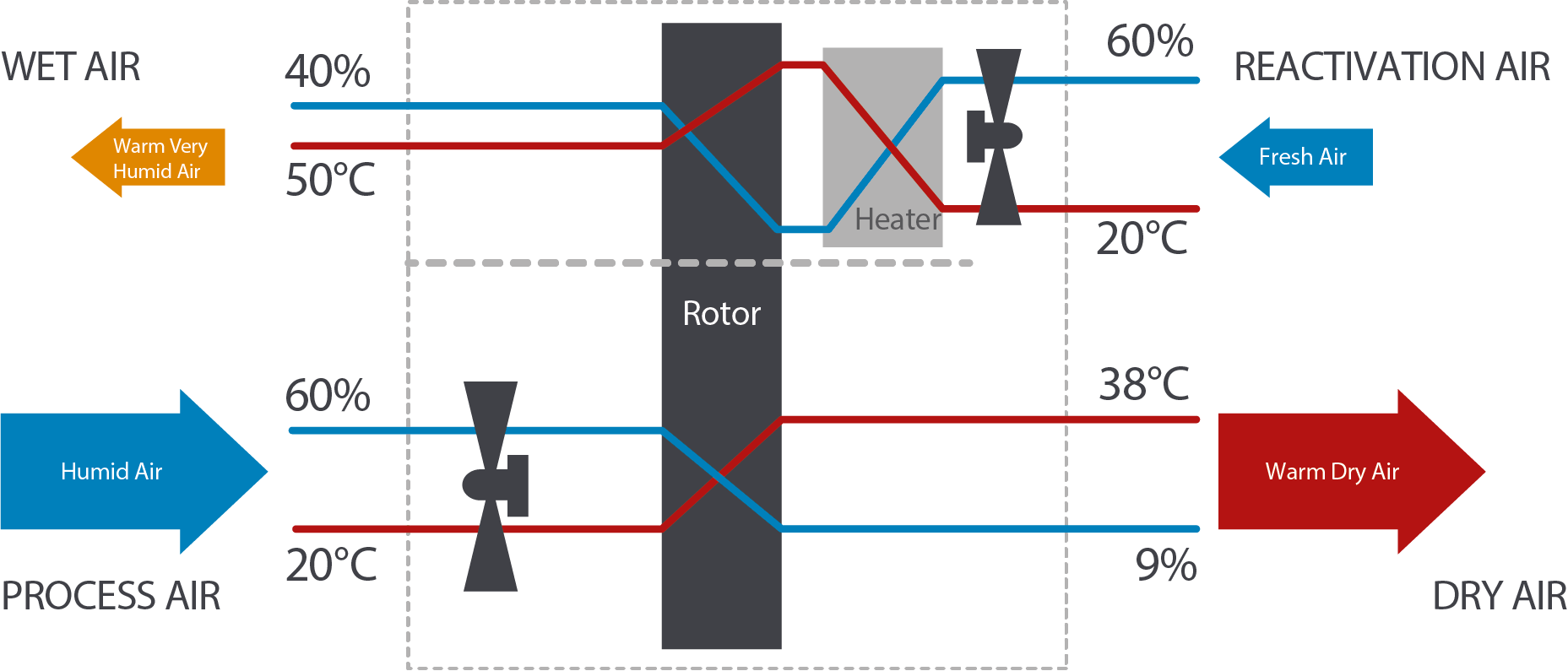

Calorex desiccant dehumidifiers are designed for both large and small pharmaceutical and scientific settings. They can operate at low temperatures and achieve precise levels of relative humidity. Here’s the basic principle behind how they work:

The air to be dehumidified (process air), passes through a slowly rotating silica gel rotor.

The desiccant material attracts the moisture to its surface, removing it from the air stream (dry air).

A second, smaller air stream (reactivation air) usually heated to around 120°C, is required to remove the moisture from the rotor.

This (wet) air must then be exhausted to atmosphere using a duct. Slowly rotating the rotor through both airstreams creates a continuous dehumidification process.

Key benefits:

High moisture removal rate in a single air pass

Achieve very low absolute humidity levels

Can operate in low temperatures and at low humidity

Fast, efficient, and specifically designed to achieve a high level of accuracy, Calorex dehumidifiers are a top choice for leading pharmaceutical production facilities. To learn more about choosing the right system and optimising it for your environment, don’t hesitate to get in touch to speak with our team.

Related products

Featured insights

Important reasons to implement an effective climate control system in your facility

How to optimise humidity during food production

Discover how humidity control is critical to effective data storage

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.