Why heat is so hard to handle in aircraft hangars

- Home

- Insights

- Cooling insights

- Why heat is so hard to handle in aircraft hangars

Aircraft hangars are extremely susceptible to hot temperatures and notoriously difficult to cool down. In this article, we explain how evaporative air cooling helps combat the uncomfortable working conditions faced by military aircraft engineers and aerospace personnel.

Climate control is a particular challenge in any building with a lofty ceiling, but there are a number of factors that make matters more difficult in aircraft hangars. Their most notable difference to any other industrial facility is the size of the doors which, not only need to be big enough for an aircraft’s wingspan, but often remain fully or partially open while the hangar is in use.

As warm outdoor air floods into the building, heat can become trapped inside the hangar, leaving the environment hot and stagnant for employees and personnel. In a military and aerospace setting, general aircraft maintenance includes everything from repairs to painting, which can emit fumes, dust and debris into the atmosphere.

While large doors will help with the supply of fresh air, in a busy environment where personnel is working intensively for the fast turnaround of aircraft, ventilation is still an important consideration.

What is the most appropriate solution?

To achieve comfortable working conditions and fresh air circulation, many aircraft hangar operators turn to portable evaporative air cooling. With planes and equipment moving around the space, mobile solutions are ideal for creating a cool atmosphere in busy areas without obstructing operations. As well as being more convenient, this also means that energy isn’t wasted in places where people are not working.

When using traditional fixed air-conditioning is impractical and too expensive, evaporative cooling systems like the Master BC 341 are a great choice for military and aerospace requirements. Once plugged into an electrical socket and connected to a water supply, the unit is ready to deliver powerful cooling.

How it works

Evaporative cooling units take advantage of the natural process of evaporation to take warm air from a stifling atmosphere and turn it into a fresh cold breeze.

The process:

A fan draws hot dry air across cooler pads which absorb water from a reservoir.

When the hot air crosses the cooler pads, the water molecules on the surface evaporate and lower the air temperature inside the system.

This fresh air is circulated around a building, forcing hot stale air outside.

The benefits:

Spot cooling

Offering power and flexibility, portable evaporative systems can bring cool air exactly where it is needed.

Energy usage

Because they harness the natural process of evaporation, Master evaporative coolers offer outstanding energy efficiency.

Convenience

While most traditional cooling systems need a well-sealed environment to be effective, evaporative cooling units can operate at maximum efficiency while doors remain open.

Hygiene

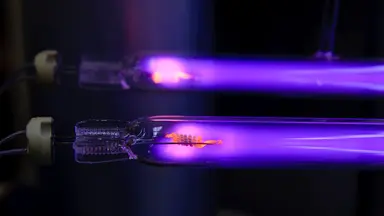

Since the COVID-19 outbreak, Master evaporative coolers have been equipped with UV lights to kill any viruses and bacteria that may be in the water used to cool the air.

To learn more about Dantherm Group's industry-leading evaporative air coolers, including the BC 341, or for advice on controlling climates in military and aerospace aircraft hangars, fill out the form below to get in touch with our team of experts.

Related products

Featured insights

Improving air quality for the sake of public health

How UV light can help prevent viruses spread in production facilities and aircraft hangars

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.