Why air purification is vital for pharmaceutical production

- Home

- Insights

- Air cleaning insights

- Why air purification is vital for pharmaceutical production

This article covers the importance of clean air circulation within a pharmaceutical production environment. You’ll find out how industry leaders are seeing the benefits of high-power air cleaning units to maintain the efficiency, quality and safety of their output.

Good manufacturing practice (GMP) in the pharmaceutical industry is part of the quality assurance which ensures that drugs and medicines are produced and controlled to standards that meet the requirements of their intended use.

In pharmaceutical production, where there is no room for even the tiniest of errors, an unregulated atmosphere can spell disaster. To reduce the risk of cross-contamination, mould and bacterial growth, as well as health hazards to staff, the strict hygiene standards in every facility should include the constant circulation of fresh contaminant-free air.

Two ways that low air quality cause problems...

Airborne contaminants can infiltrate a facility via ventilation from outside, through air-conditioning units, vents, or in air flow from other parts of the building. They could also emit from materials used in the facility, such as compressed gas, cleaning and sterilising agents, plastic and stored materials.

The failure to maintain a carefully controlled environment can be detrimental to two vital aspects of pharmaceutical manufacturing:

#1 Product safety

Contaminants of any kind can tamper with the effectiveness of drugs and medicines, making them ineffective or even unsafe.

This danger is heightened in facilities that produce antibiotics in addition to other drugs. If cross-contamination occurs, traces of antibiotics can find their way into other medicines and trigger allergic reactions in some patients taking them.

#2 Employee wellbeing

Staff working in pharmaceutical production are exposed to dust, raw materials and potentially hazardous particles on a daily basis. During the development of new products, staff may also be working with nanoparticles that can easily be inhaled due to their microscopic size.

Drugs such as steroids, hormones and cytotoxics can be particularly harmful to those working on the production line and lead to lung inflammation or lung damage over time.

How to ensure clean air in your facility

In an industry technical report by The World Health Organisation (WHO), ventilation temperature and relative humidity are listed as essential design considerations for ensuring the prevention of contamination and cross-contamination of products during manufacture and storage.

For expert advice on air purification in pharmaceutical and scientific environments, simply fill out the form below to get in touch with our team.

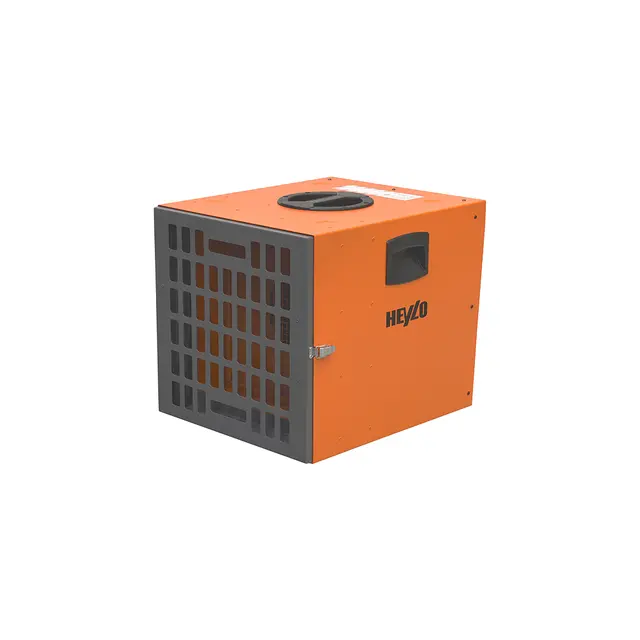

Related products

Featured insights

What to do when the atmosphere becomes a hazard

What makes waterworks susceptible to condensation?

Achieve air filtration efficiency of no less than 99.95%

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.