Vertical farming climate control: Optimising yields and energy costs

- Home

- Insights

- Humidity control and drying insights

- Vertical farming climate control: Optimising yields and energy costs

With the importance of vertical farming set to skyrocket in the coming years against potential food crises, we speak to Dr William Stiles – Lecturer at Aberystwyth University and Director of Vertikit – about this technology and the process of making it more energy-efficient and cost-effective for today’s farmers.

There is no escaping the fact that the world’s approach to agriculture will need to change significantly in the foreseeable future.

“At this moment in time, we are changing the way we produce food”, says Dr William Stiles. “The ways we have done so up to now can be environmentally damaging and are increasingly precarious as a production system under the construct of climate change.”

“In the next decade or so, challenges in maintaining crop production are going to be more and more common. While this may not necessarily mean crop failures each year, it could cause major food insecurity across the Northern Hemisphere.”

With these very real prospects on the horizon, vertical farming – also known as Controlled Environment Agriculture (CEA) – represents the future of crop cultivation. A future where food production can be more controlled and optimised than ever.

Here, we explore CEA, address the elephant in the room of energy costs, and explain how Dantherm and Vertikit create vertical farming climate control solutions that combat these expenses.

What is vertical farming?

Vertical farming or CEA is an agricultural process where crops are grown on top of each other indoors, allowing for growing conditions to be optimally controlled to improve both yields and the quality of produce. It can be conducted anywhere from a small shed or greenhouse, to substantial facilities and warehouses.

With the increased likelihood of major crop failures post-2030 due to climate change, this technology is going to be critical to the planet’s ongoing food security.

“The crux of why CEA is essential is that it can contribute to food security,” says Dr Stiles.

“When you are looking at the potential of mass famines across the globe due to crop failings caused by extreme weather – scenarios that are very realistic from 2030 onwards – having technology in place to switch from field production to CEA production instantly guarantees we will have some food output in any conditions.”

Learn more about controlled environment agriculture.

Advantages of indoor vertical farms

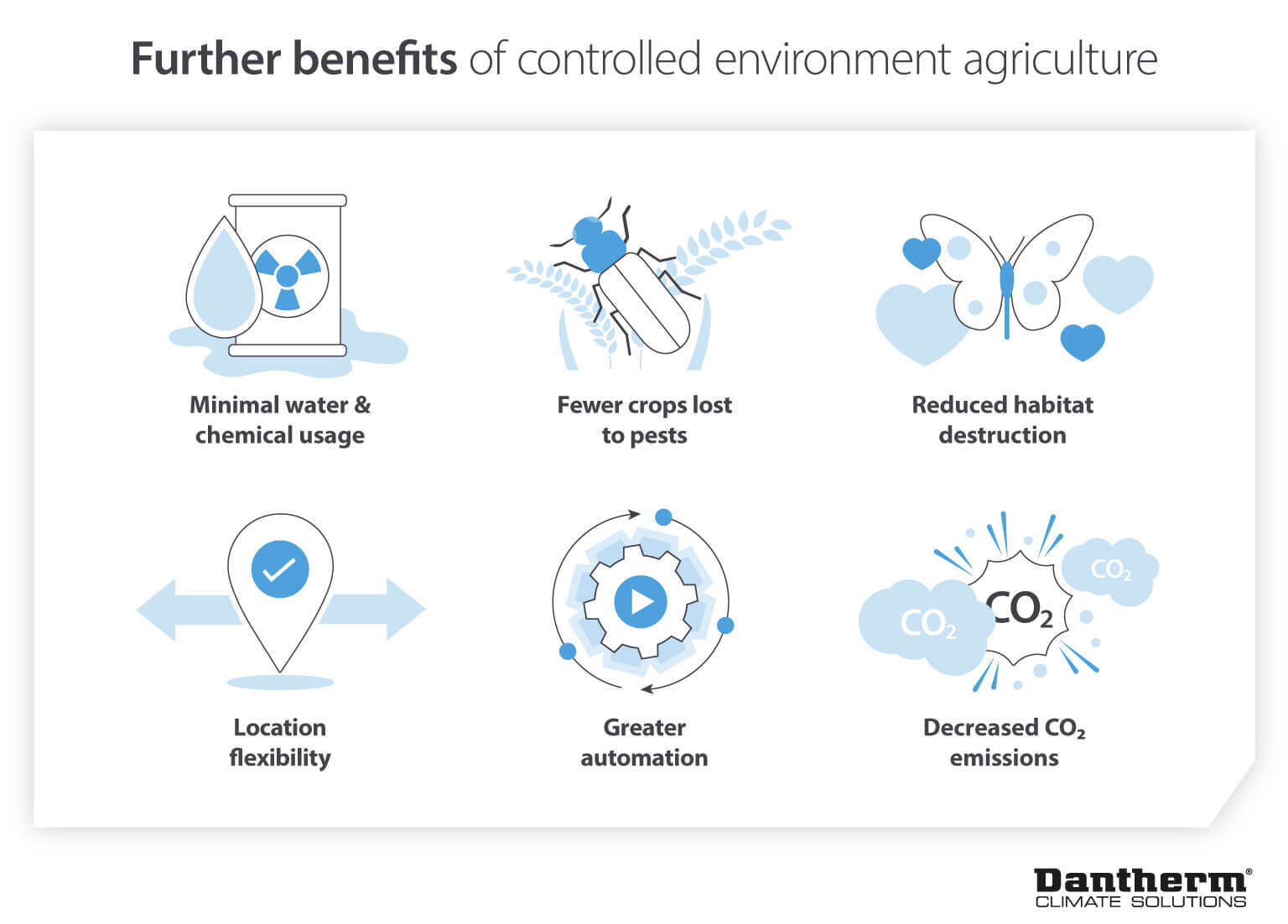

Beyond the vital security of food production, CEA presents numerous benefits over traditional farming practices:

Greater crop yields and quality

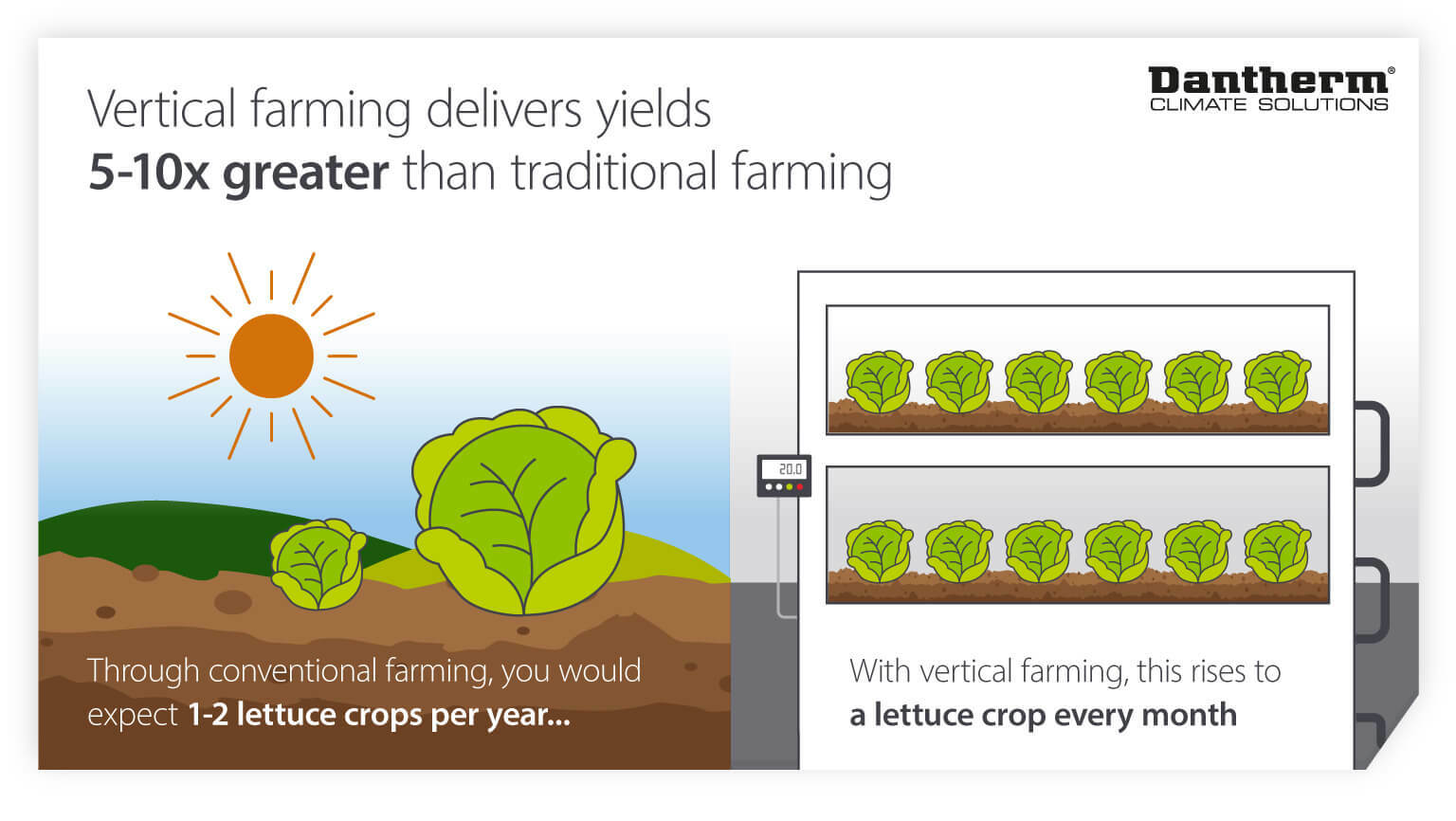

As well as increasing the consistency of crop production, vertical farming improves yields substantially and can enhance their overall quality. As an approximation, this method is anywhere between 5-10 times more efficient than traditional farming.

For example, on a ‘standard’ lettuce farm, you would anticipate 1-2 crops to be harvested per year. In a well-controlled vertical farm, you are likely to harvest a crop every month.

Furthermore, the relatively compact nature of vertical farming can enable growers to diversify their offerings with greater success – useful in a time where just 5% of farm income comes from ‘farming’.

Control the growth of key products

Vertical farming enables growers to fix the environment surrounding plants however they choose. You can compel plants to grow in a certain way or produce materials in greater abundance by placing specific environmental stresses on them.

“Plants have a high degree of plasticity,” explains Dr Stiles. “They are unable to move if conditions are suboptimal for growth, so they have to adjust their physiology in order to manage environmental stress.”

“Therefore by inducing certain stresses, it is possible to compel plants to adjust their body form and chemical structure. This can result in the production of compounds which may be beneficial from a production perspective."

A good example of this is daffodils, which are known to produce a compound called galantamine; a material used in Alzheimer’s medication. The production of this compound is increased when this plant is cultivated in upland environments (a phenomenon referred to as the ‘Black Mountain Effect’, named for where it was first observed). But cultivating plants in upland environments is challenging.

Instead, using CEA technologies growers can recreate the exact environmental conditions needed to maximise production of this compound, in circumstances where production is manageable and consistent.

These precisely controlled environments also enable the consistent development of desirable consumer foodstuffs, such as red cress, or the opportunity to grow crops not native to certain countries.

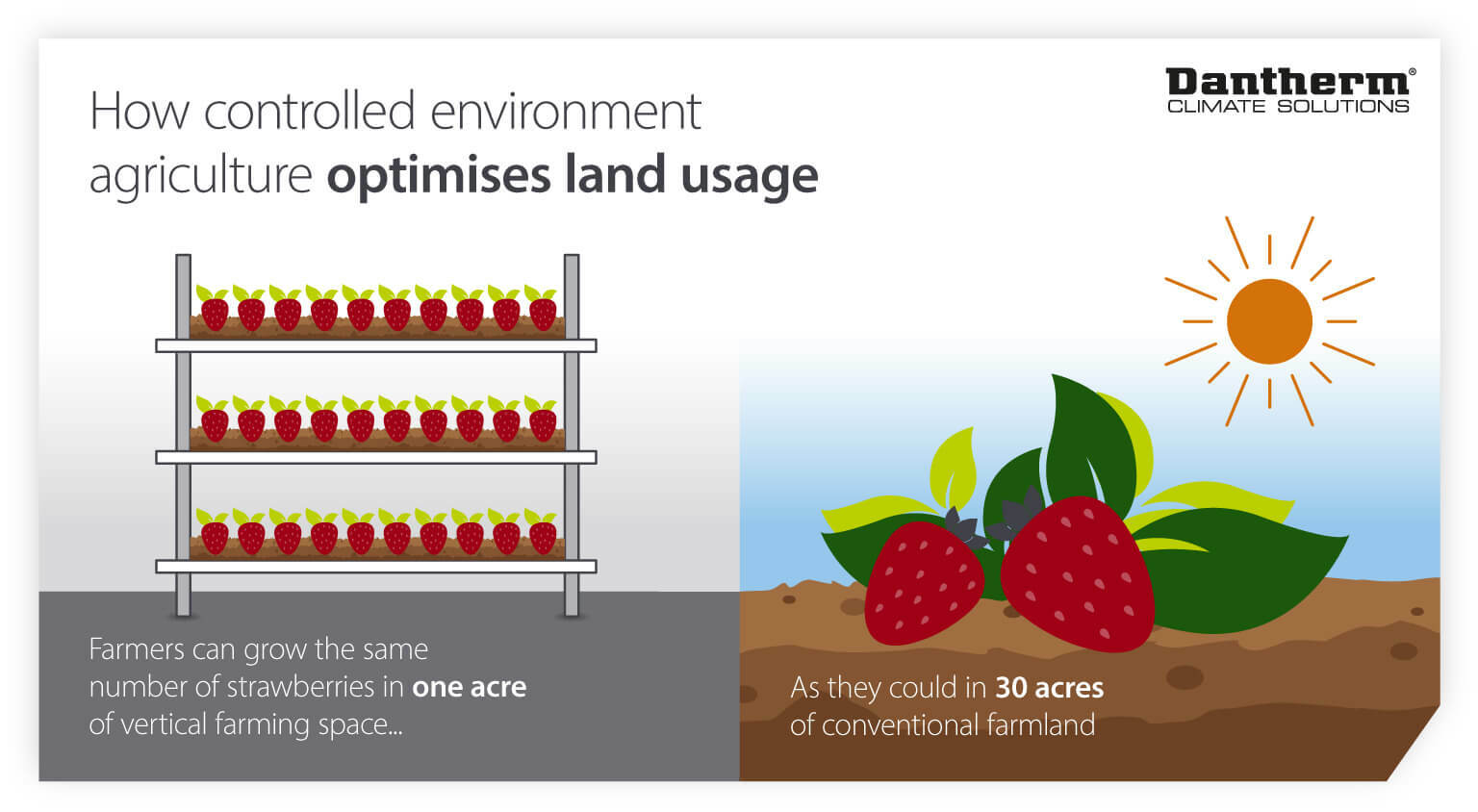

Reduced land degradation

When crops are stacked vertically in a purpose-built facility, the land-saving potential this offers is truly game-changing:

For regional farmers, this approach can allow you to dedicate a shed or a small container for each crop, and repurpose farmland for other uses, such as growing alternative crops or diversifying the land.

Why is climate control essential to vertical farming?

Effective climate control is the heart of vertical farming’s improved yields and year-round growing potential. This technology maintains the temperature, humidity, air quality and more that crops need to grow at their optimal rate and quality.

With the right dehumidifiers, heaters, coolers and air handling systems in place, any farmer can create the ‘perfect summer’s day’ (or perfect winter’s day depending on the crop!) in a shed or a container, and maintain these conditions 365 days a year.

What are optimal conditions for growing crops?

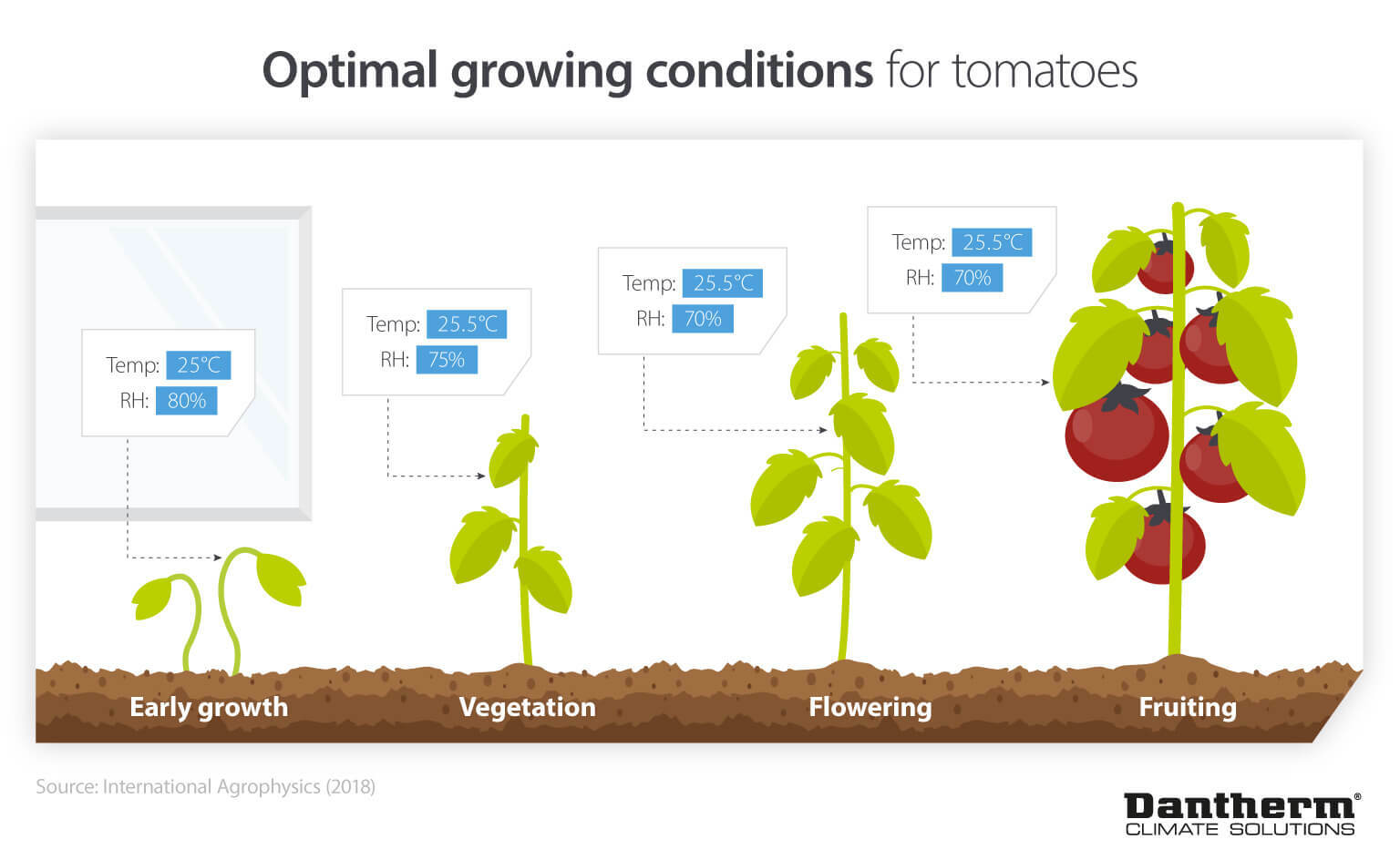

While this varies significantly depending on which crop you intend to grow, many plants thrive in temperatures of around 25ºC and humidity of 65% RH. However, the optimal climate for a plant will change at different stages of its development:

What are the main climate control challenges for vertical farming?

In the vertical farming projects we have supported at Dantherm, one of the most prominent challenges has been heat loads. LED lights, dehumidifiers and other factors add significant heat to these enclosed spaces.

We have helped deliver dehumidifiers with remote condensing units (RCU) that simultaneously cool the air while managing humidity. In larger CEA facilities, our effective air handling systems provide comprehensive temperature, humidity and air quality control.

We have also advised on solutions to control vapour pressure deficit (VPD). This drives transpiration from a plant’s stomata and is greatly influenced by the surrounding humidity. Most plants thrive with a VPD between 0.4 and 1.6 – any lower or greater and a plant can lose its ability to photosynthesise.

Working closely with farmers starting out in CEA, we have helped introduce suitable, energy-efficient dehumidification solutions that ensure VPD levels stay in an ideal range.

The energy costs of vertical farming

In spite of the incredible possibilities presented by vertical farming, energy demands have so far prevented it from becoming the new standard for farmers.

“The problem with CEA is that it's massively energy-intensive, and energy is expensive – particularly in the current context,” explains Dr Stiles.

“Compared to conventional farming systems, it is an expensive production approach, which consequently means the produce cultivated must be of sufficiently high value or produced in sufficiently greater quantities to offset the higher cost.”

Vertical farming has largely been restricted to the production of high-value goods, such as microgreens that fetch a high price at farmer’s markets.

At this early stage in CEA’s development, it is difficult to make growing grains and other general crops economical against its energy requirements. But, as the need for vertical farming grows, this is something that must be addressed in the foreseeable future.

"CEA is highly likely to become mainstream because of the challenges we face,” says Dr Stiles. “It currently receives a lot of criticism because people can't visualise how it can ever be economic – but when you're facing widespread food shortages, the cost of energy may no longer be the principal governing factor."

Reducing the energy costs of indoor farming

For farmers looking to diversify through vertical farming, what can be done now to reduce energy costs?

First, we recommend starting small with CEA, rather than diving headfirst into a large facility. This will enable you to understand the challenges involved in growing a particular crop, and gradually add the technology you need to address these.

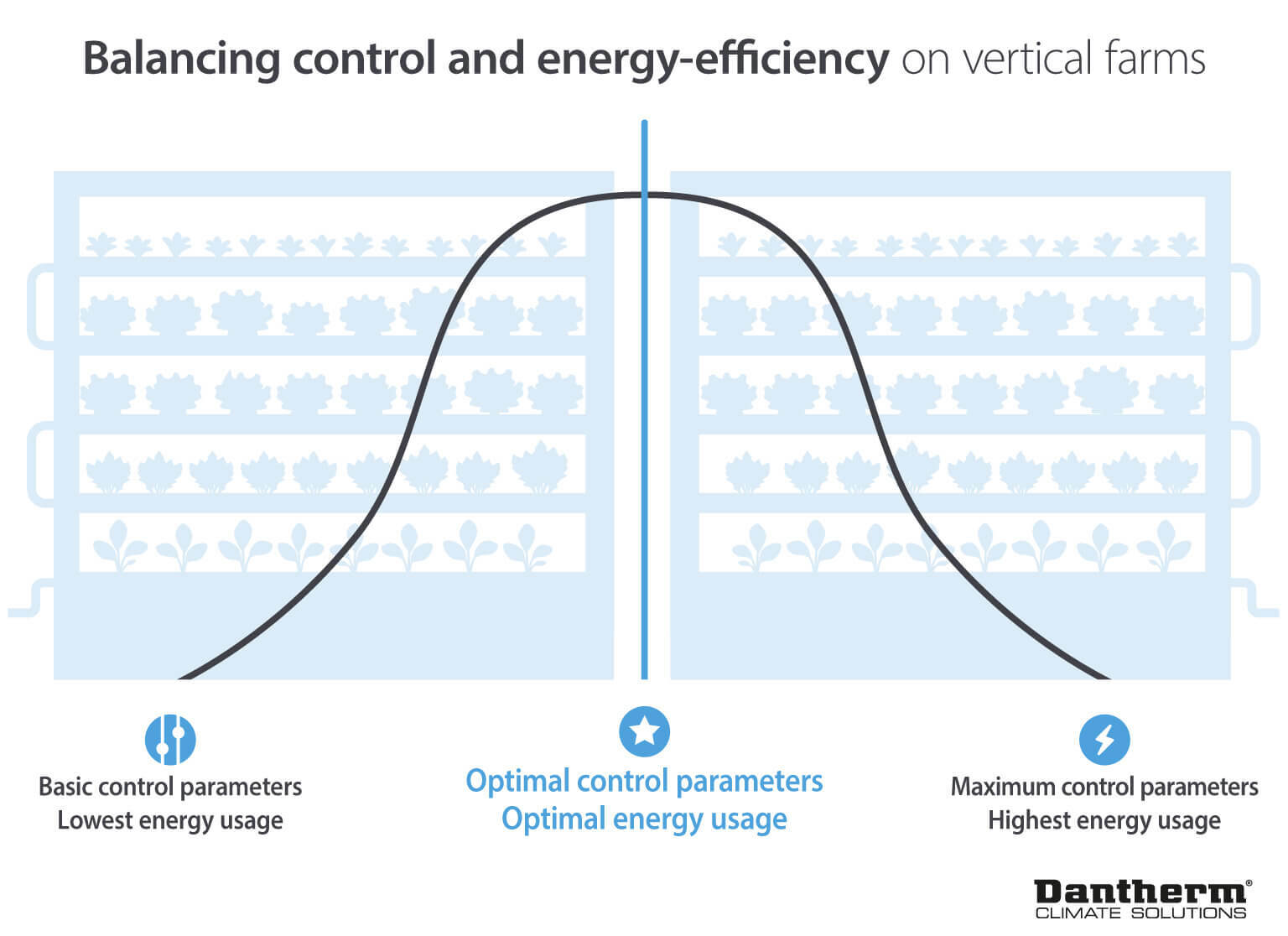

From there, it becomes a question of balancing control parameters against energy costs. Think of this as a bell curve – on one side is 100% total control over conditions, but a big energy bill. On the other side is a more basic setup, but with smaller energy demands.

Your ideal solution will sit somewhere between those two points. You will need to sacrifice some control and concentrate energy usage on the most important variables – temperature, humidity, lighting, water, nutrients, etc.

This is more effective when you understand what crop you are growing and what you intend to achieve. Whether this is maximum yields, creating a particular product, or growing crops of a certain colour or shape, you can build your climate control setup around these goals.

Finally, to reduce vertical farming energy costs, it is wise to invest in energy-efficient technology.

LED light bulbs save energy when influencing the light wavelengths on your plants. Heat recovery technology repurposes energy cost-effectively. Dehumidifiers and air handling units with automatic control settings keep conditions optimal and restrict energy spend.

Get started with Controlled Environment Agriculture with Dantherm & Vertikit

At Dantherm, we recognise how crucial vertical farming is for our long-term future. That is why we have invested in developing solutions that help to minimise the expense for farmers seeking to set up these facilities – a goal shared by our partners at Vertikit.

“I was speaking a great deal with growers looking to enter the CEA space, but were financially unable to do so,” explains Dr Stiles. “The cost of a pre-built vertical farming container is approximately £100,000 (€116,000), which is a prohibitive investment for many existing food production businesses.”

“Vertikit works to source the technology that could create these controlled spaces more cost-effectively. We sought out units such as dehumidifiers, which led us to Dantherm Group.”

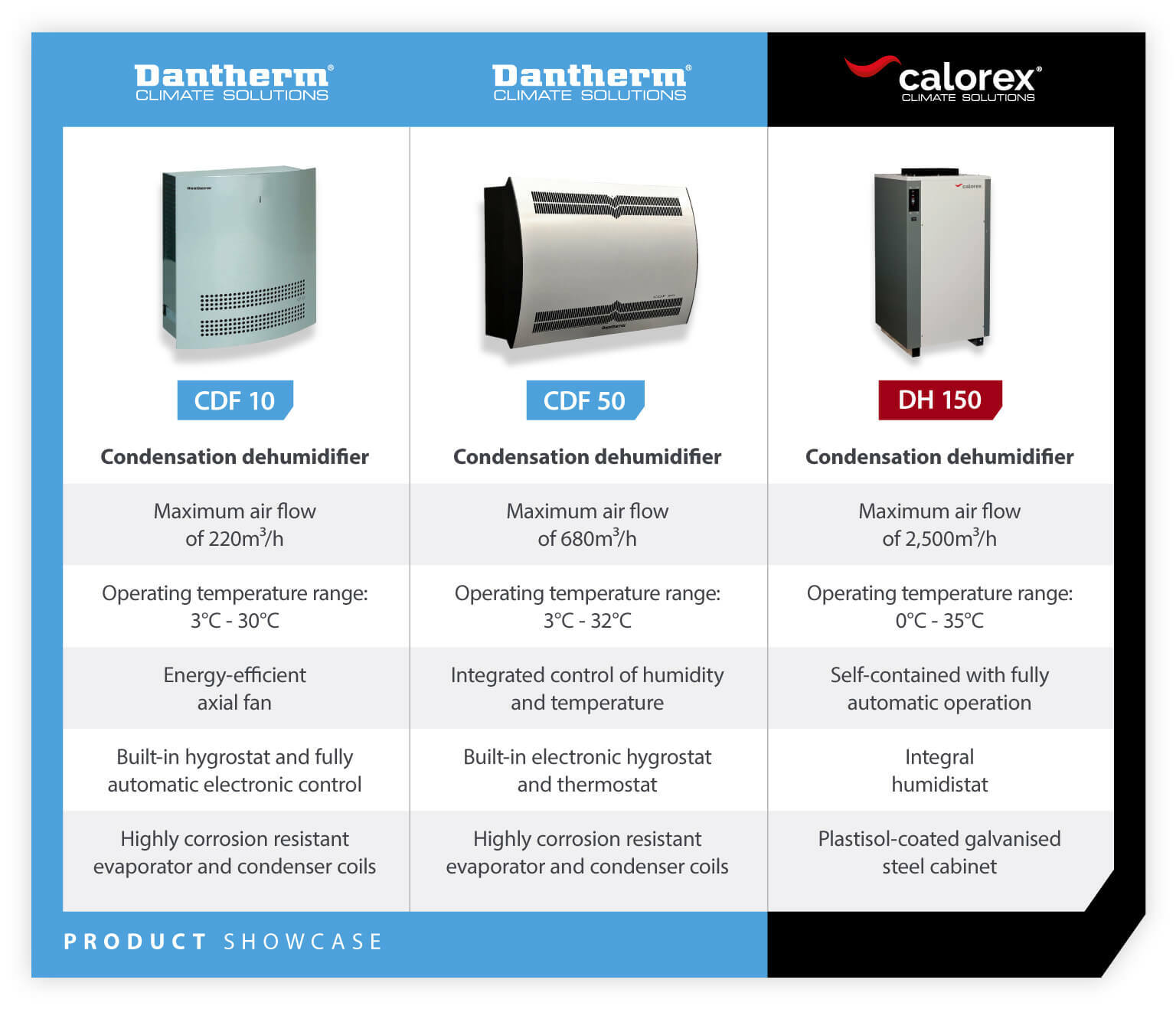

Our range of vertical farming climate control solutions, ranging from efficient dehumidifiers for CEA startups, to powerful air handling systems for larger facilities, enables us to help growers create ideal setups at any stage of their vertical farming journey.

But at Dantherm, we are more than a product manufacturer – we are a solution provider. With decades of climate control expertise, we devise fitting, cost-conscious systems that meet your needs. And with access to the agricultural expertise of Dr Stiles and the team at Vertikit, we can direct our customers to the ideal consultant for crafting a complete, efficient CEA setup.

“We believe this is a technology that is absolutely essential for our future,” says Dr Stiles. “Our entire purpose is to get this industry to actively work and be commercially viable, so we diversify quickly enough to avoid the worst-case scenarios in terms of lost food security.”

“We’ve had an enormous amount of help and support from Dantherm. They have opened up pathways for us that would not have been possible otherwise to support our continued growth.”

If you are interested in exploring the potential of vertical farming, or are interested in our wider range of agricultural climate control solutions, get in touch with our team today using the form below.

Dr William Stiles is a Lecturer at Aberystwyth University for BioInnovation Wales. He leads the Knowledge Exchange Hub in IBERS for Farming Connect and Biomass Connect, and is Director of Vertikit.

Related products

Featured insights

How regional farmers can take advantage of agriculture’s most promising innovation.

Exploring the importance of controlled crop drying.

Learn how effective climate control solutions can support the need for sustainability in the food industry.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.