The value of evaporative cooling in the automotive industry

- Home

- Insights

- Cooling insights

- The value of evaporative cooling in the automotive industry

Automotive environments must carefully control their indoor climate, but the rising cost of energy is making this a more expensive consideration. In this article, we discuss how evaporative coolers are helping generate impressive savings in a Mexico-based car manufacturer.

Although 80 million cars were produced in 2021 alone, the manufacturing process behind these products is incredibly complex and involved.

As well as the assembly of potentially hundreds of intricate components, indoor conditions at these manufacturing and production facilities must be carefully controlled throughout the year.

Car factories are not the only arm of the automotive industry that demands precise temperature, humidity and air quality control. Vehicle showrooms and automotive storage centres all rely on climate control technology as well.

However, with the cost of energy skyrocketing around the world, automotive companies, dealerships and garages are facing significant rises to their energy bills.

Here we discuss why climate control is a must in the automotive industry, the advantages of evaporative cooling, and how these systems are proving an efficient, effective solution for a Mexican-based car manufacturing company.

Why is climate control a necessity for the automotive industry?

Modern motor vehicle production centres require dozens of large and heavy-duty machines, hundreds of workers, and numerous heat-intensive processes, including welding and soldering, to successfully assemble a car.

If these procedures go unmitigated, temperatures can quickly build and cause materials such as plastic and wood to warp. Excess heat can also present a risk to workers on the ground and allow dizziness, dehydration and heat stroke to take hold.

Temperature is not the only element of the climate that must be controlled in these manufacturing facilities. The presence of excess moisture in the air can cause bodywork to corrode and staff comfort to plummet.

Additionally, it is important to maintain good air quality inside. Processes such as glueing, screwing and welding emit unpleasant fumes. Without a solution renewing the air, unpleasant contaminants can build up and add to worker discomfort.

It is not just factories that rely on effective automotive industry climate control. Dealerships, workshops and garages also demand total climate control.

Why is evaporative cooling the solution of choice?

The demands of an automotive facility can vary based on the number of workers inside, the volume of the area, as well as the country or climate the premises are situated in.

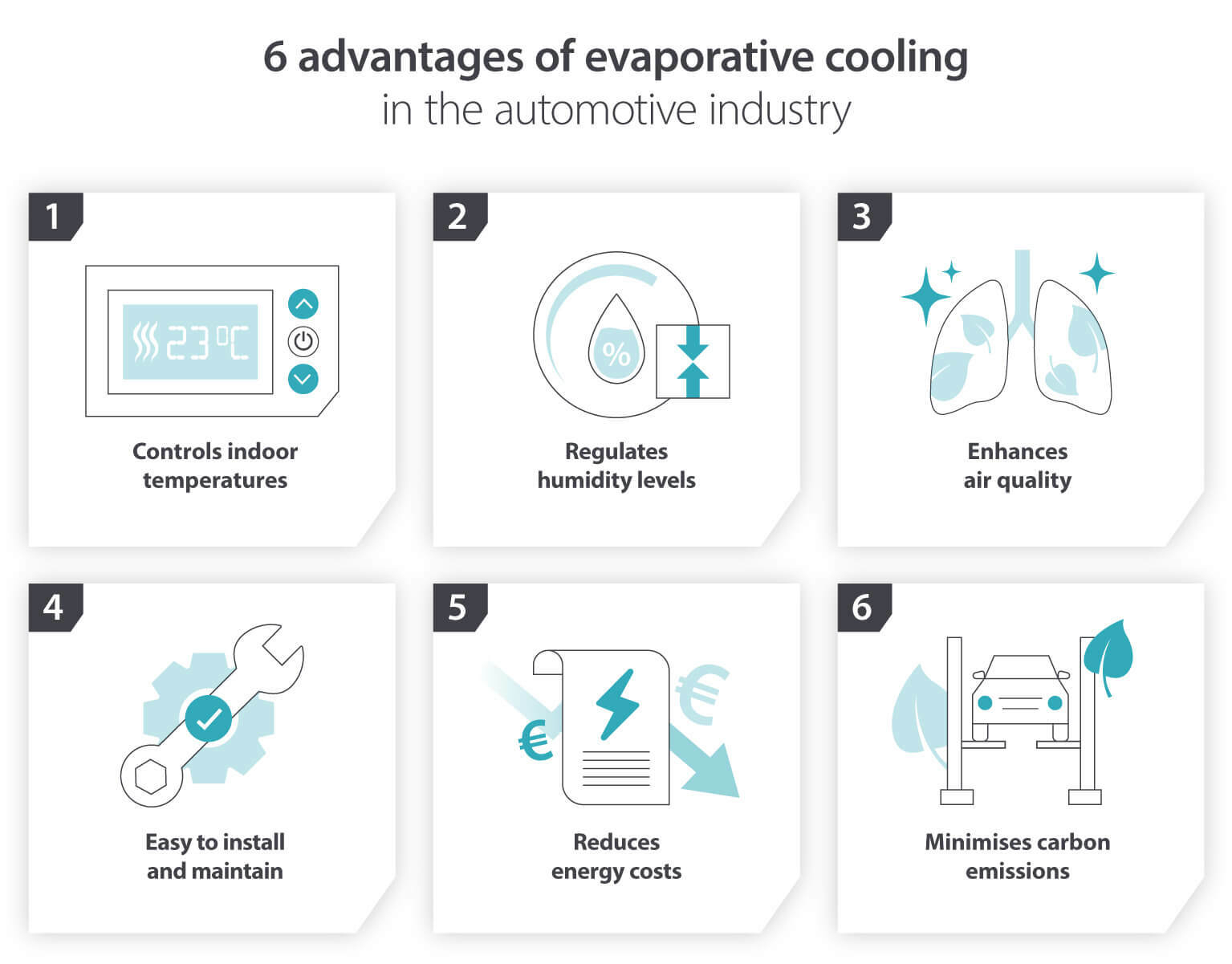

Despite this, evaporative air coolers are the solution of choice for most automotive applications. This is because these systems harness the power of evaporation to cool air extremely efficiently, controlling temperature, humidity and air quality simultaneously.

How does it work? Evaporative cooling solutions draw fresh outdoor air through a wet membrane. Here, moisture is evaporated along with unwanted heat from outside, creating a flow of clean, cool and suitably dry air using nothing more than the natural process of desiccation.

Evaporative systems improve on conventional air-conditioning systems in several key ways.

Firstly, because A/C relies on consumptive compressors to cool spaces, its energy efficiency is comparatively poor. In large spaces with open doors or windows, the cost-effectiveness of this equipment only worsens. In comparison, evaporative coolers work just as effectively when doors and windows are open in a space.

Additionally, air con relies on refrigerant-based gases to effectively cool air. These substances are not only finite, they emit harmful greenhouse gases that damage the environment.

Beyond the poor economy and environmental credentials of traditional air conditioning, these units are also unable to regulate air quality, simply cooling and moving air that is already in the room. This means the same stale air festers, making conditions worse for inhabitants and increasing the risk of illnesses spreading.

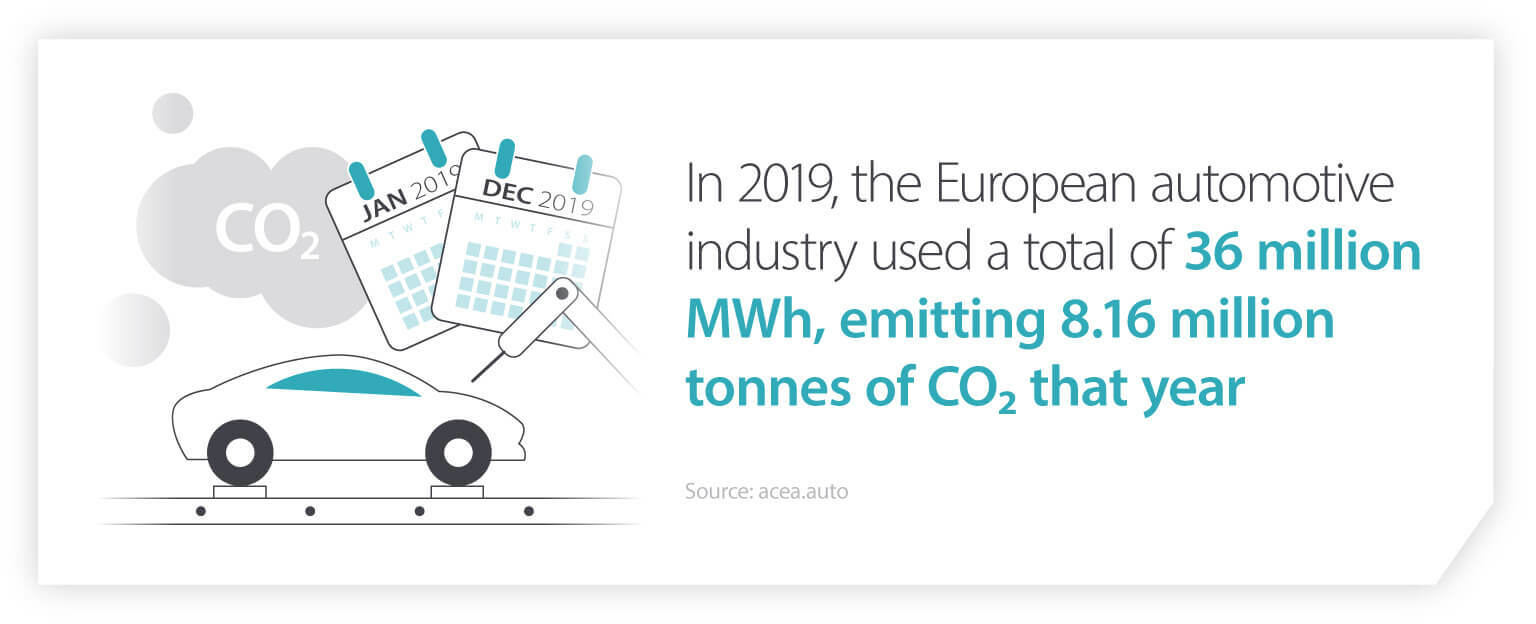

For one of the most consumptive industries, evaporative cooling does not just represent an opportunity to reduce running costs. It also offers dealerships, workshops and factories a way to reduce the ecological impact of their operations – an increasingly important topic.

How evaporative coolers are creating ideal conditions inside a Mexican car manufacturer

Evaporative cooling systems are already helping create ideal working environments in the automotive sector.

In a recent example, Biocool worked closely with a Mexican-based car manufacturing plant to achieve and maintain optimal conditions throughout their large industrial space.

What problems did the automotive manufacturer face?

Faced with hot temperatures throughout indoor work areas, the comfort of teams on the ground was beginning to deteriorate and slow down the manufacturing process.

To rectify these key issues, managers identified a need for an air cooling system that could service their large 10,000m² space. The solution had to offer effective temperature control and keep work areas below 27°C and between 23°C and 24°C in wind chill. Relative humidity also had to be kept at or below 65%.

What was the ideal solution?

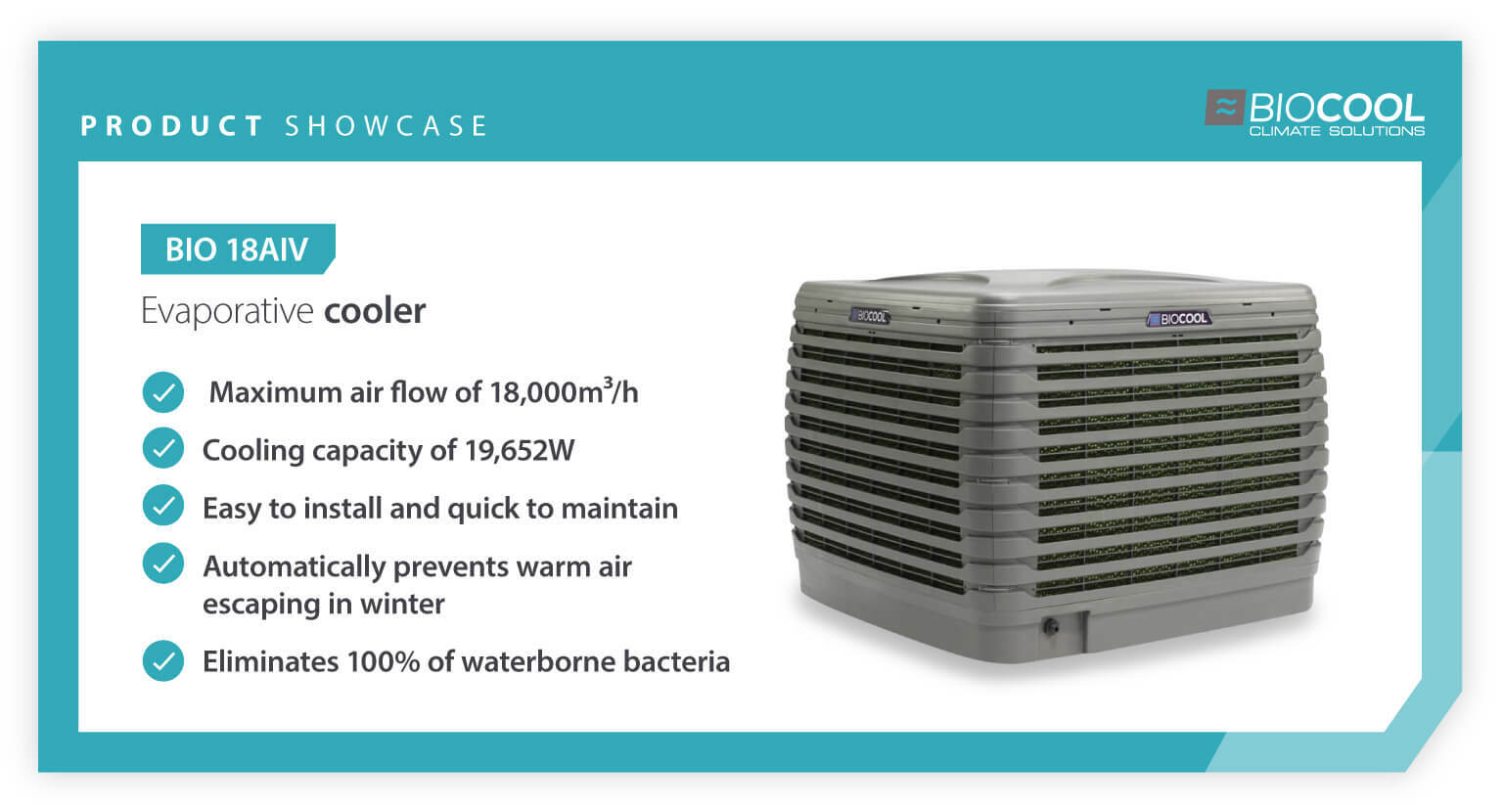

Both conventional air conditioning systems and evaporative cooling systems were considered, but after assessing the needs of their space it was determined that the BIO 18AIV evaporative cooler was the best fit for the project.

After one week of assessment and one month of installation, a total of 36 units were deployed throughout the factory in two phases.

Paired alongside these units were several Smart City Cooler controllers, which provide on-site humidity and temperature control.

These devices allowed the Biocool engineers to remotely configure systems, detect problems, and train the client in how to use their coolers.

What was the outcome of this project?

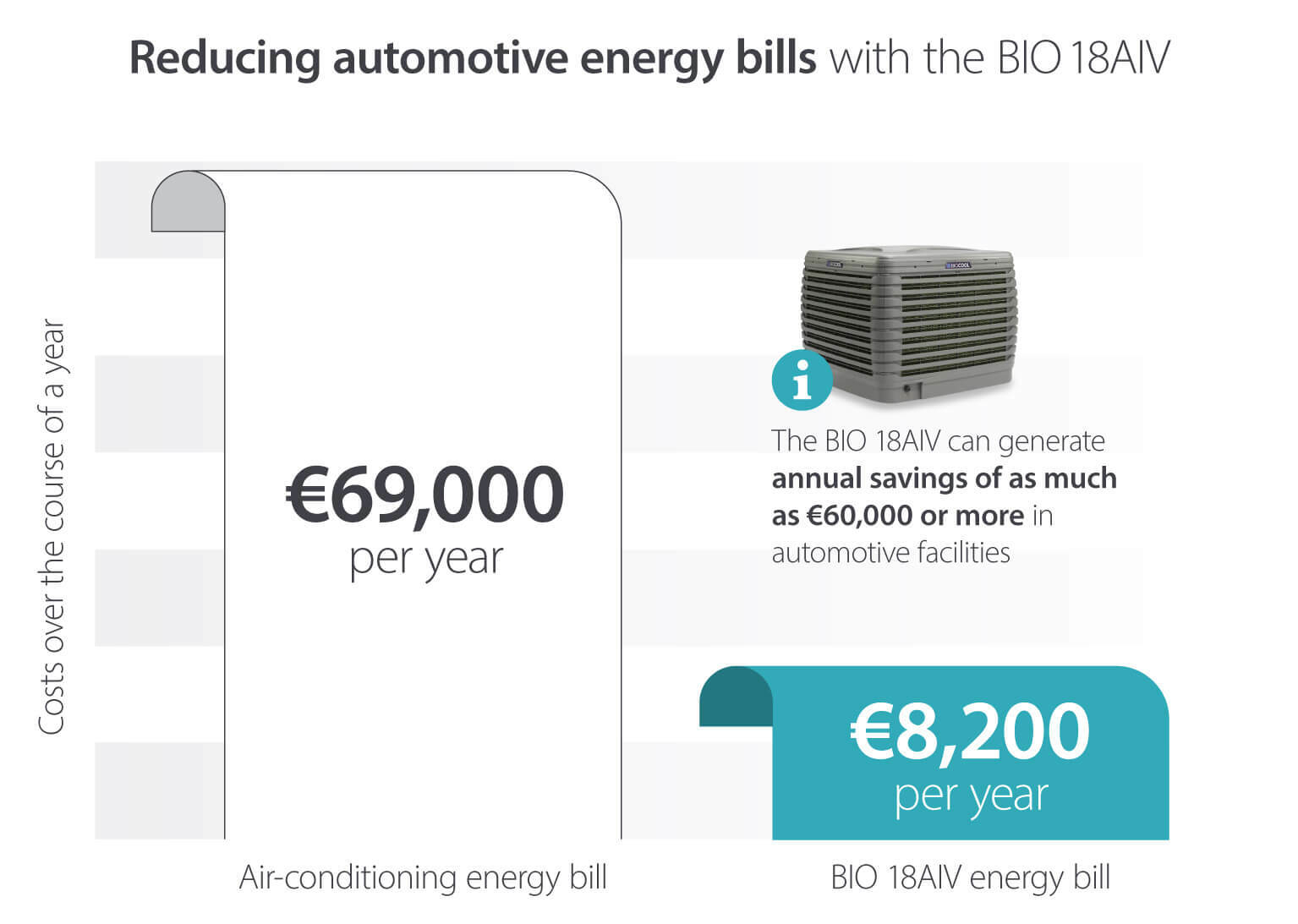

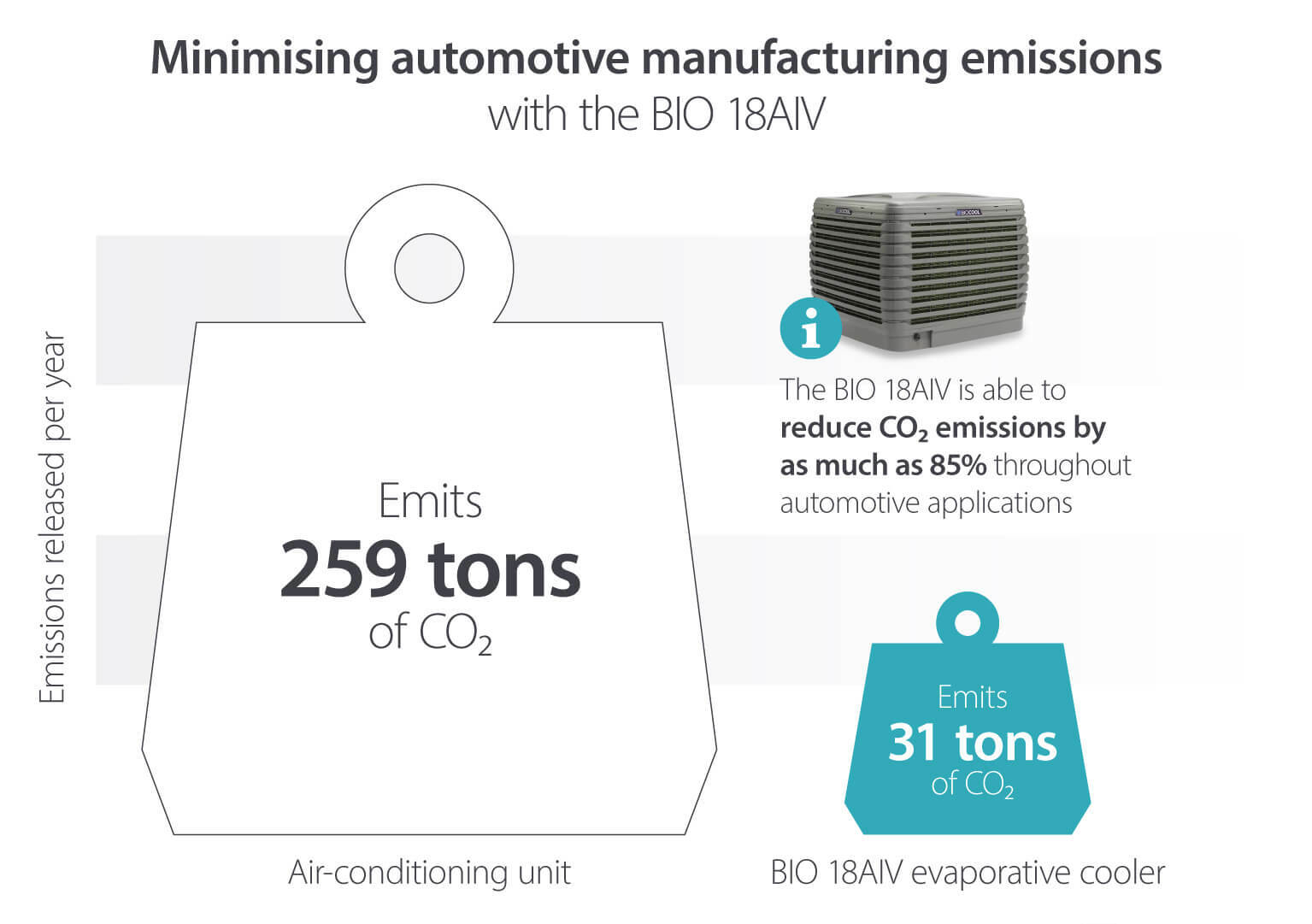

The result of the project has been very positive. Not only are the units helping maintain optimal conditions inside the facility all year round, but it is also helping the car manufacturer limit their energy bills.

Beyond the impressive cost savings this technology has generated, the BIO 18AIV is working to minimise the emissions of production in a big way.

Bring a new level of efficiency to your facility

Although evaporative cooling represents one of the most efficient and cost-effective ways to cool large industrial spaces, not every evaporative cooler is built to the same standard.

In order to have a meaningful impact on the amount of energy your facilities use, and the emission they generate, it is crucial to work with a trusted manufacturer.

With more than 20 years of experience, and a proven track record delivering climate control that generates results, Biocool is the go-to provider for efficient, sustainable and durable commercial air cooling systems.

To learn more about the BIO 18AIV, as well as our full range of evaporative cooling solutions, get in touch with one of our experts today by completing the form below.

Related products

Featured insights

Stay ahead in the automotive industry with evaporative air cooling

Learn how evaporative cooling helps workers overcome the risks of high heat loads.

See the capabilities and benefits of evaporative cooling over alternative methods.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.