The need for tailored air handling solutions in pharmaceutical settings

- Home

- Insights

- Cooling insights

- The need for tailored air handling solutions in pharmaceutical settings

In this article, we explain why bespoke air handling is a necessity across pharmaceutical sites, and how Dantherm’s expertise allows us to educate clients and install technology that delivers meaningful results for years to come.

What climate control challenges do pharmaceutical facilities face?

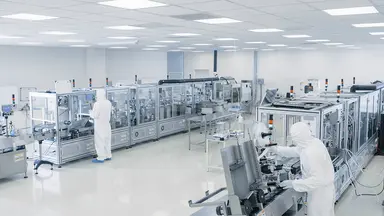

Whether it is a scientific laboratory, a pharmaceutical packaging line, a medicine production factory or a storage centre, precise and effective commercial air handling solutions are a necessity in practically every pharmaceutical and scientific setting.

This is because the goods created and stored in these settings are held to a very strict standard, necessary to guarantee the efficacy of the product and the safety of the consumer.

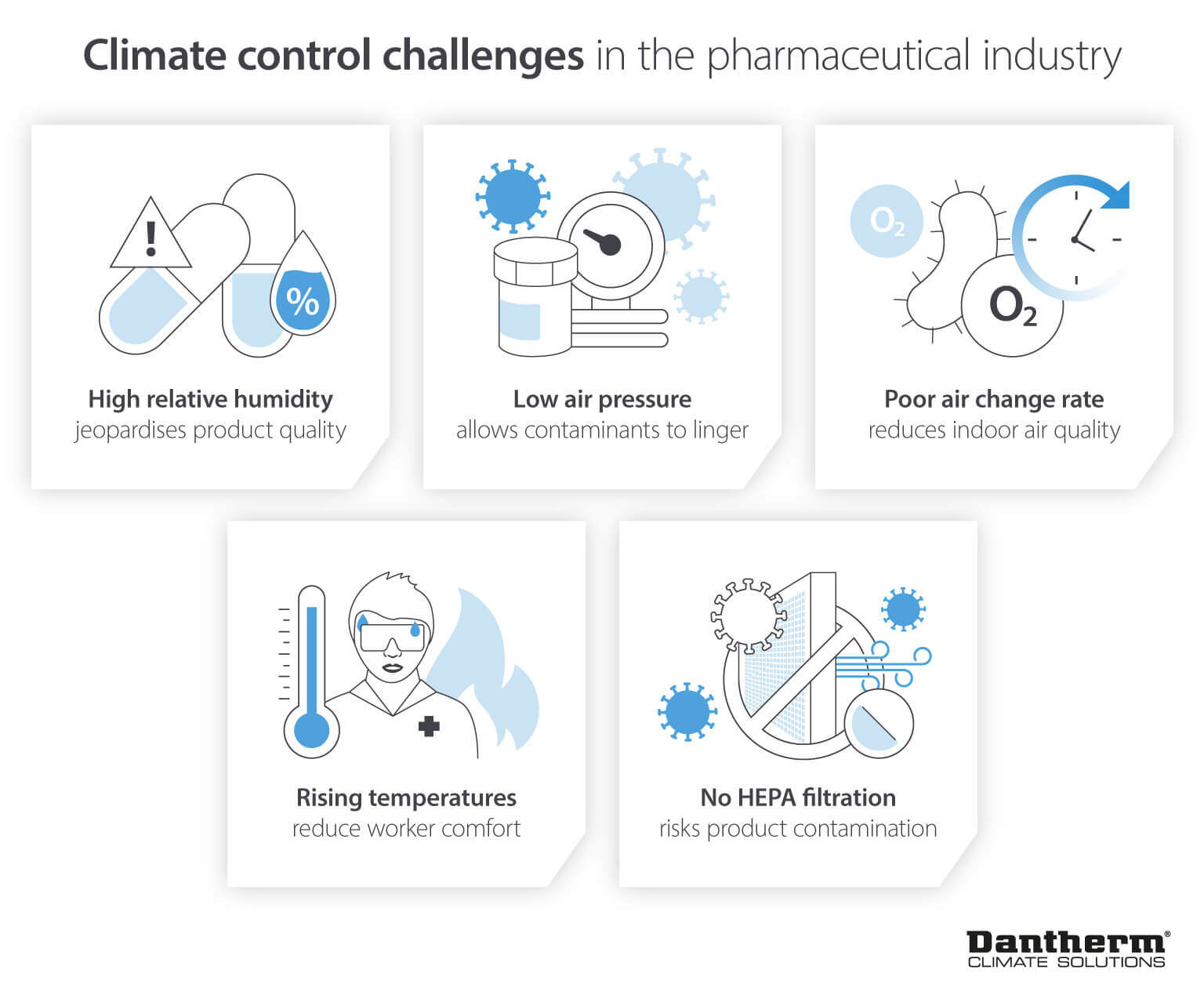

Relative humidity

Without technology able to regulate relative humidity, hygroscopic materials will readily absorb moisture from the air, causing powders to become sticky and unfit for purpose. Packaging becomes at risk of cosmetic or physical damage as it absorbs more and more moisture.

Temperature

Chilled moulds become a target for condensation as high relative humidity air condenses on cold surfaces, leading to product defects.

Air change rate

Without a way to deliver the necessary amount of air changes per hour, or introduce clean filtered air into these precise settings, the hygiene of facilities can be compromised and the risk of product contamination increases.

Air pressure

In addition, units incapable of providing sufficient volumes of air can create negative pressure zones, allowing unwanted infiltration of contaminants from outside of the controlled environment and increasing the risk of cross-contamination.

The consequences of failing to meet a facility’s needs

If any of these elements are not adequately controlled, facility conditions can fluctuate and compromise the quality of products. Manufacturing can be brought to a halt and result in entire batches being discarded – an incredibly costly and disruptive mistake.

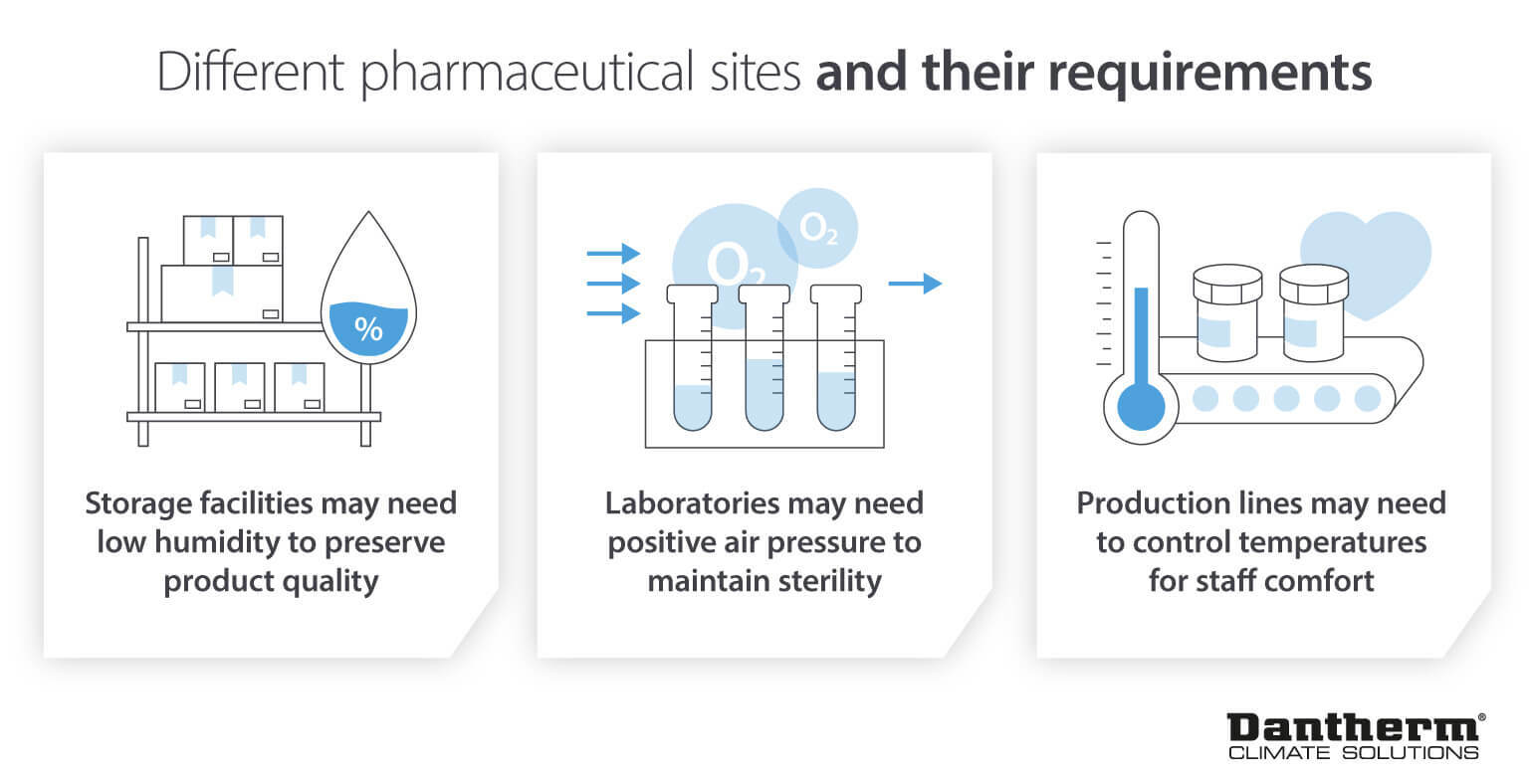

To exacerbate these difficulties further, distinct spaces in these facilities have different requirements. Depending on what is produced, the size of a facility, the external climate and other factors, the needs of a building will vary enormously.

Fulfilling your facility’s needs, then, requires a built-for-purpose commercial air handling solution. One designed to your unique specifications and backed by a trusted manufacturer.

As climate control experts, our team at Datherm have the knowledge to deliver meaningful results and exceptional value. In fact, pharmaceutical sites have relied on our solutions for more than 40 years.

Why bespoke air handling units are the optimal solution

As noted above, the distinct requirements of each pharmaceutical site and the repercussions of poor climate control make purpose-built air handling units essential in these facilities.

But the value of bespoke systems goes beyond maintaining ideal conditions in these meticulous settings. Built-for-purpose technology plays a key role in minimising energy consumption.

Taking strides toward a cleaner, greener future cannot only help reduce operating costs, but also improve sustainability – a topic that holds greater value for consumers and legislators with every passing year.

In our experience, sustainability is an area ripe for improvement in the scientific and pharmaceutical industry. We often see sites that rely on effective, inefficient setups to deliver the required performance. Some common examples include:

Air handlers that deliver full fresh air to facilities 24/7, even when unnecessary

Decades-old systems unable to generate the efficiency of modern equipment, with drops in performance often going unnoticed

Units that do not harness sustainable heat recovery

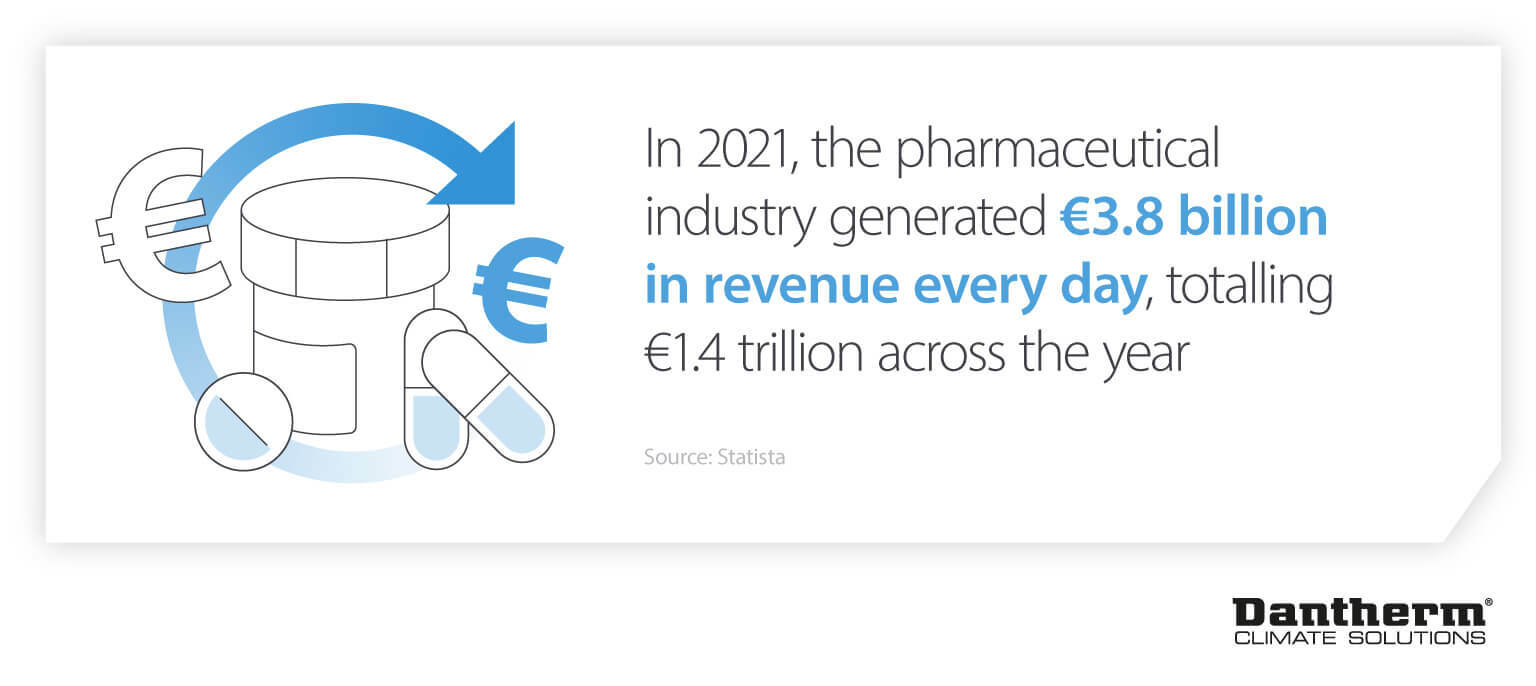

The prevalence of over-specified configurations likely contributes to this sector’s excessive energy consumption, as data suggests that pharmaceutical facilities worldwide spend over €1 billion on energy annually, and emit 55% more emissions than the automotive sector.

To establish the right balance between the needs of a pharmaceutical setting and its energy consumption, tailored commercial air handling solutions deliver the exact amount of airflow required in an area and include specific features that limit energy waste.

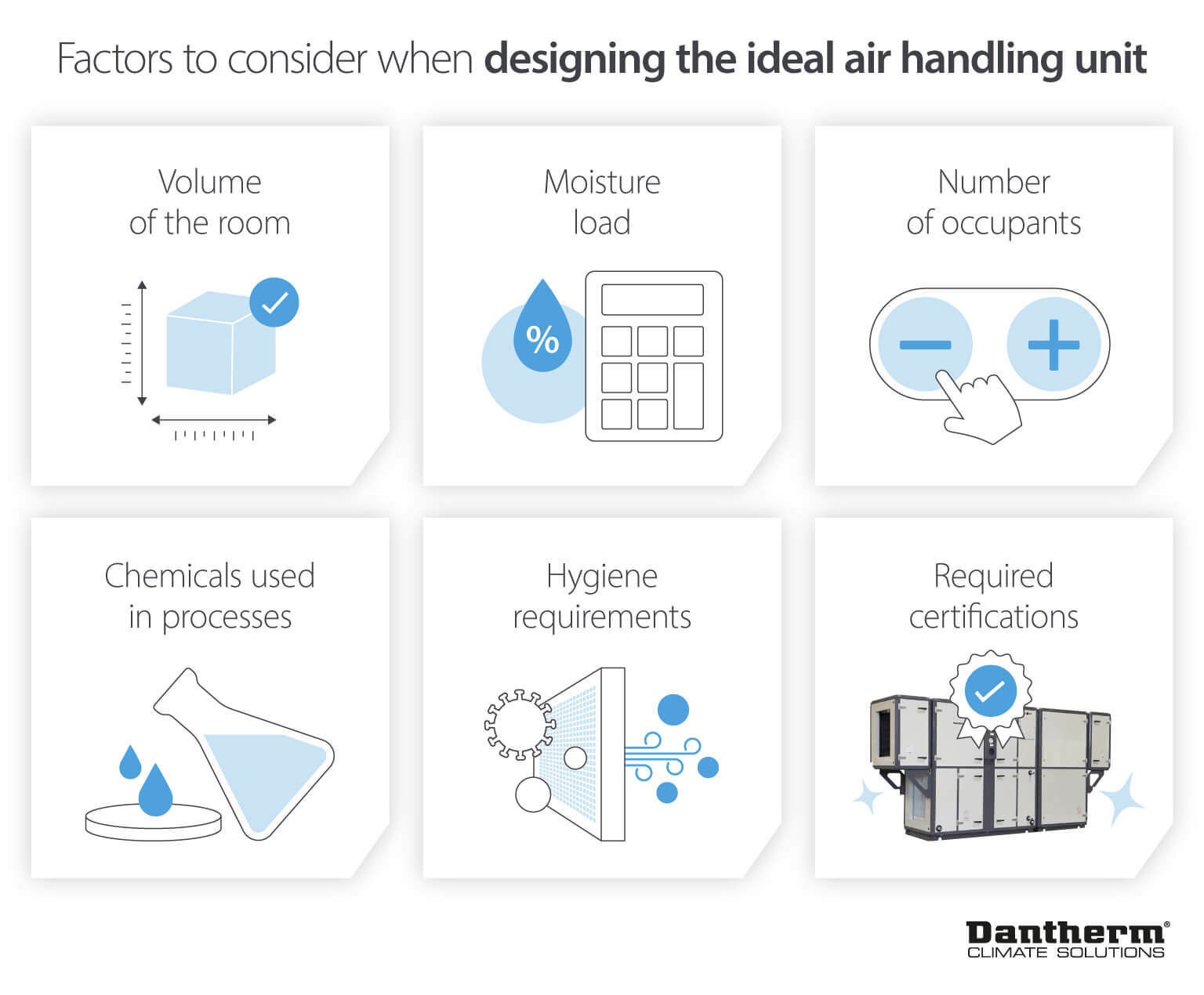

In any project, our expert technicians will consider internal and external conditions, seasonality and more key factors to deliver the strict performance required, while minimising ongoing costs:

The value of expertise in pharmaceutical climate control

There is no ‘one size fits all’ solution when it comes to efficient and effective pharmaceutical climate control. From unique features and materials to the dimensions and layout of the system – every air handling installation will have its own nuances and specificities.

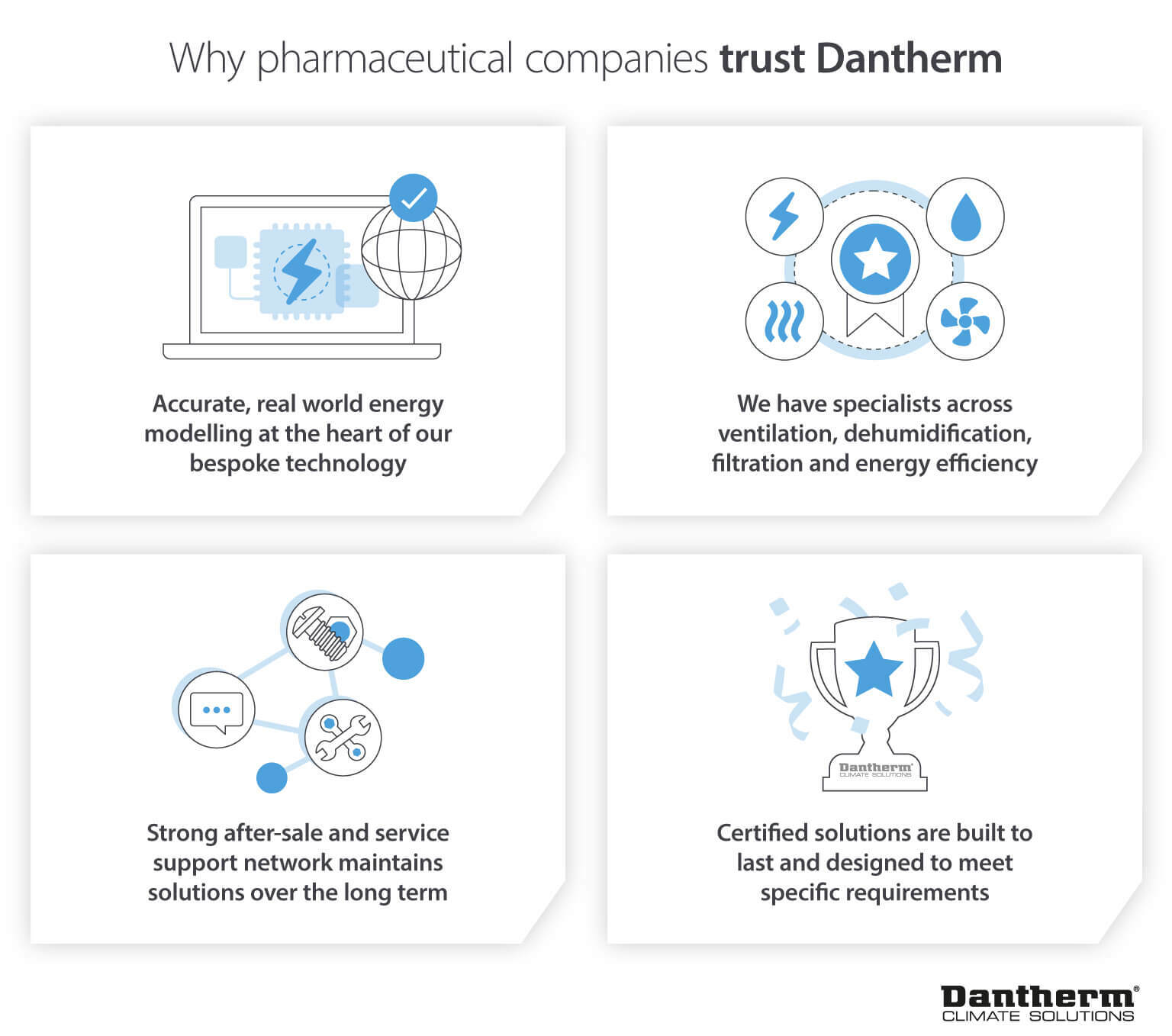

That is why it is important to employ a specialist manufacturer able to guarantee that the specific requirements of your project are catered for. One that not only has vast experience, but certified technology at its core.

With decades of experience designing and providing fit-for-purpose air handling technology for laboratories, pharmaceutical manufacturing plants and stores, we create solutions that deliver meaningful results.

Whether it is sizing a unit to meet specific building regulations, or employing a distinct selection of components to deliver the desired amount of hourly air changes, we are uniquely positioned to fine-tune air handling systems for any scenario.

Talk to the experts

Meeting the stringent standards of pharmaceutical products is a difficult task, but a necessary one in order to keep work running smoothly and production profitable.

Although commercial air handlers can manage all elements of the indoor climate, relying on an off-the-shelf system in these unique settings is unsustainable. To deliver the right performance and limit energy waste, built-for-purpose systems are key.

Working with Dantherm gives you access to industry-leading knowledge that can guarantee your parameters are met, your running costs are slashed, and costly downtime is kept to a minimum.

If you are looking to design and install air handling systems unique to your facility, speak to our team to benefit from our trusted advisors and our exceptionally engineered products.

Related products

Featured insights

Regulating humidity levels for pharmaceutical production

The importance of keeping the atmosphere clean

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.