The importance of sustainable food industry climate control

- Home

- Insights

- Humidity control and drying insights

- The importance of sustainable food industry climate control

With the need for sustainable agriculture and food production growing each year, here we discuss how the right climate control solutions can play a key role in enhancing sustainability and reducing this industry’s impact on climate change.

Sustainability is increasingly sought-after in all aspects of life, and in fewer places is this more fitting than in agriculture and food production. Global food production has a powerful influence on our environment today and, unless changes are made, will have unwanted consequences on our futures.

From farmers producing the raw ingredients that feed the world every day, to those processing, transporting, storing and selling food for the masses, every link in the food production chain is being compelled to make their activities more environmentally friendly. When it comes to sustainability, the situation is truly ‘farm to fork’.

Here we will outline the challenges and problems the food industry faces in relation to climate change, and how effective agriculture climate control solutions can help those in this industry progress in a more sustainable, efficient way.

Why is sustainability so important in the food industry?

The EU defines sustainable development as “development that meets the needs of current generations, without compromising the ability of future generations to meet theirs”.

This is particularly relevant to the food production industry, which provides the food we eat, supports millions of livelihoods, and manages a large share of the landscape.

However, many facets of conventional food production, be it in growing and livestock management, to supplying food to supermarkets across the globe, do not have the long-term viability that our planet requires. The food industry is facing a wide range of pressures, including:

Finite resources and dependence on fossil fuels

An ever-expanding population

The health consequences of poor diets, especially in developing countries

Decreasing biodiversity, putting pressure on our food chains

Water shortages in parts of the globe

The increasing urbanisation of potential farming areas, resulting in a lack of land space

Soil degradation, reducing its viability for growing different types of food

With the importance the world places on agricultural productivity, there is understandably a great deal of urgency placed on making this as viable as possible for the long term. The EU’s common agricultural policy (CAP) has ambitions to mitigate the impact the industry has on the climate, soil quality, biodiversity and other areas. Similarly, the UK government is committed to reducing greenhouse gas (GHG) emissions across the economy by at least 80%.

These challenges, and the commitments made by global bodies, demonstrate how pressing the issue of sustainability is in the realm of food production.

How does the food industry contribute to climate change?

Research conducted by the University of Illinois determined that food production worldwide accounts for approximately 37% of global greenhouse gas emissions. It is also estimated to contribute 17.3 billion metric tonnes of carbon dioxide each year – 19 times more than the commercial aviation industry.

This is comparable with The Intergovernmental Panel on Climate Change (IPCC) Special Report on Climate Change and Land in 2019, which estimated agriculture alone is directly responsible for 8.5% of all GHG emissions – primarily methane, nitrogen dioxide and carbon dioxide – with an additional 14.5% coming from land-use change.

There are numerous elements that contribute to the substantial carbon footprint that conventional agriculture and food production systems leave, including:

Livestock production

Pesticides

Manure and chemical fertilisers

Large quantities of water

Ploughing of soil

Food wastage

Deforestation

Food transportation (domestically and internationally)

Energy costs of machinery

Each of these factors can have a notably negative impact on the environment, and accelerate the process of climate change. This in turn causes further problems for the agriculture industry – as climate change occurs, suitable land, water availability, biodiversity, etc. suffers, making it even more difficult for the food production industry to meet ever-growing food demands.

In short, improving the sustainability of food production is vital not just for the long-term success of the industry – it is critical for the future of our planet as a whole.

How climate control solutions can support sustainability in the food industry

So, what role can climate control technology play in creating a sustainable future for the food industry? By creating truly controlled environments, these solutions can make a telling difference at all stages of food production.

Controlled environment agriculture (CEA)

The area where climate control solutions stand to make the biggest difference to the food industry is in the development of controlled environment agriculture (CEA). This approach is widely considered to be the future of farming worldwide, enabling the production of plants, fruits, crops and more in any setting, at maximum efficiency.

In a nutshell, CEA is indoor farming – creating facilities where produce can grow and thrive in sealed, fully controlled environments. This could be a converted barn or farm building, to warehouses, storage containers and tunnels. There are even CEA facilities housed underground.

In these settings, everything plants need is provided artificially and in exact quantities. Water, heat, humidity, fresh air, light, CO2 – everything is supplied at the optimal amount for specific crops. This helps to ensure maximum yields, efficient growth, and the highest quality produce. Furthermore, as they are kept indoors, there is no risk of outside contamination (including E.coli) or the need to use pesticides.

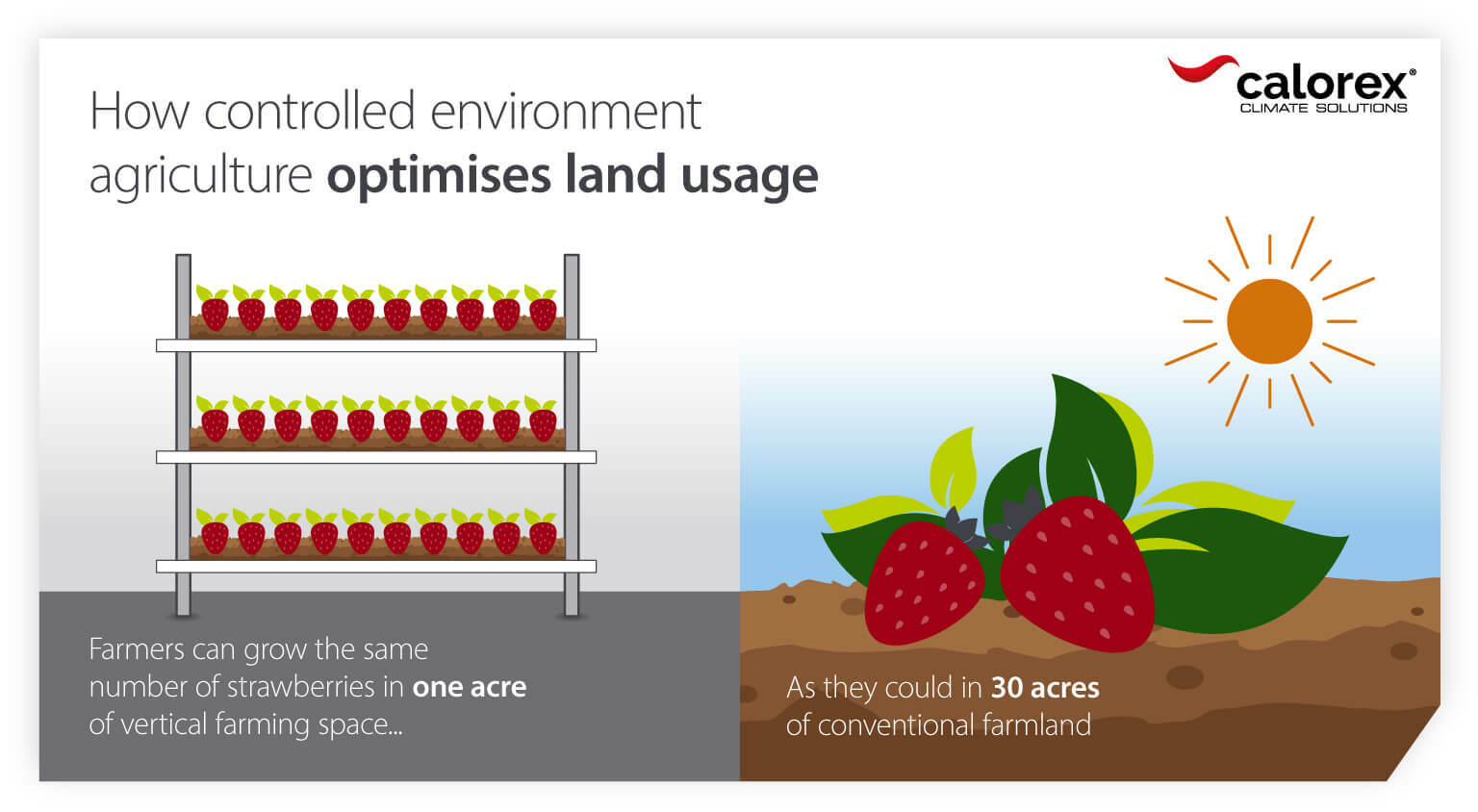

The most obvious saving is in land usage. For example, if you are growing strawberries, conventional farming would require 30 acres to produce the same amount as one acre of vertical farming space.

CEA is game-changing for the sustainability of agriculture. There is significantly less need for heavy machinery, herbicides and fertilisers, all notable contributors to GHGs. Water resources are tracked, so are never overused – CEA requires between 70%-95% less water than conventional farming. Many crops can even be grown without soil, gaining their nutrients from other means.

But the benefits do not end there. As CEA can feasibly occur in any controlled indoor environment, this can facilitate locally grown, quick-to-market produce, in the exact quantities nearby supermarkets, grocers and vendors require. This localisation of the food industry will reduce the negative impact transportation has on the supply chain, and the need to use preservatives or wax coatings to keep produce consumer-ready.

In short, food can be locally sourced throughout the globe, even in highly urbanised areas, the major problems of food prices and wastage are addressed, and produce is healthier, sustainable and of a higher quality, which will enhance food security.

Farmers in Saudi Arabia already apply CEA to grow fresh produce in places where the outdoor climate and heatwaves make this impossible. Farmers that adopt this approach, converting existing buildings into these controlled settings, will be playing an active role in combating climate change worldwide.

Of course, the incredible future presented by CEA would not be possible with agriculture climate control solutions. Dehumidifiers, heaters, coolers, ventilation units – all are critical in creating the ideal indoor environments that crops require to grow and deliver optimal yields.

Throughout the Dantherm Group, we are working closely with those at the forefront of CEA in Europe, adapting our existing solutions to help farmers create the ideal settings to produce their crops in a productive, efficient and sustainable way.

Storage of seed and feed

While we believe that CEA will be the largest area where climate control systems will support the food industry moving forward, their capabilities do extend even further. For instance, in the storage of seed and feed for livestock farming.

Technology such as dehumidifiers and ventilation systems can help tackle the problem of condensation in areas where seeds, animal feed and other important materials are stored. Without this in place, a great deal of this could go to waste, or need to be replaced more frequently, which comes at an economic cost and a sustainability cost.

By using the right climate control solutions, seeds and feed can be stored in conditions that will keep them in good quality for longer, helping to indirectly improve the sustainability of livestock farming.

In addition, climate control technology also helps genetic engineers who are actively researching and developing new types of seed create the exact environments that these seeds will be expected to grow in. This helps ensure that when the seeds are mass-produced, they will deliver the intended results.

Crops and grain storage

Silos provide bulk storage for a variety of industries, such as crops, grain and other foodstuffs in the agricultural sector. However, these environments, if not correctly controlled, can leave the raw materials inside susceptible to spoilage due to condensation, mould growth and more.

By applying suitable dehumidifiers, the humidity within silos can be regulated all year round. This helps guarantee that no moisture damage affects these products, and they are kept in the best possible conditions before being transported to their next destination.

But, not all climate control solutions are created equal – an inefficient approach may result in energy unnecessarily going to waste, which can cause a noticeable drain on costs and sustainability. Calorex’s decades of expertise enables us to guide customers towards the most appropriate, efficient solution according to their budget.

Food processing

Many aspects of food processing and production require the surrounding conditions to be optimal to deliver the highest quality product at maximum efficiency. A few examples include:

Confectionery

As many ingredients, particularly sugar, used in confectionery are hygroscopic (they absorb water from the atmosphere), high humidity can cause sweets to clump together during production or grow mould during storage.

An effective dehumidification solution would maintain the humidity at a suitable level, so the sweets can be produced as efficiently as possible, and stored for longer periods without any drop in quality.

Dry-ageing meat

When animal products, such as beef or pork, are dried out to create jerkies, this is heavily influenced by the environment surrounding it. Too moist and the wrong types of bacteria could infect the meat. Too dry and it will occur too quickly, reducing the flavour of the final product.

Having a dehumidifier in place to maintain the humidity at the ideal levels both streamlines this process and results in the best quality outcome. This prevents unnecessary wastage and allows more to be done in a shorter window of time.

Cheese ripening

When the amount of moisture in the air is left unregulated during cheese ripening or storage, factors such as mildew, the rotting of rind and the growth of putrefying bacteria can all lead to product going to waste.

By maintaining the relative humidity (RH) during this process between 75% and 95%, this will help preserve the quality of the cheese.

In addition, for food production factories that are already embracing clean energy, such as the use of biomass boilers, dehumidifiers help maintain the correct conditions for the storage of wood pellets used in these boilers.

The exceptional energy efficiency of Calorex’s climate control products come to the forefront here, helping ensure that our customers receive the most sustainable, cost-effective solutions built around their requirements.

Warehouses and cold storage

Food wastage is a prevailing problem in the efforts to make this industry as sustainable as possible:

While much of this waste can be addressed in future with the introduction of CEA, right now ensuring that food is stored in optimal environments can help address this prominent issue. By extending the shelf-life of food products kept in warehouses and cold storage, this can limit the amount that goes to waste on a daily basis.

Dehumidifiers help maintain the conditions inside a cold store or freezer by reducing defrost cycle times and by creating a safe working environment, minimising the build-up of ice on floors, ceilings and on produce. They also help eliminate fogging outside cold stores and freezer doors.

Through this, warehouses and cold storage can play their role in addressing food waste, which in turn may leave a huge positive impression on the sustainability of the food industry as a whole.

Food delivery

A final way that climate control technology can support the food industry is in food delivery. With online food delivery growing with every passing year, particularly in the delivery of ready-made meals from restaurants, this is placing a priority on housing the cardboard boxes these meals are typically delivered in.

As a hygroscopic material, cardboard is very susceptible to moisture, meaning that if humidity is not controlled where it is stored, it can become unusable. To ensure that these are kept viable for as long as possible, allowing companies to handle this sustainably, dehumidifiers offer a powerful advantage.

Can agriculture climate control solutions help with climate change?

Determining ways to make the agriculture and food production industry more sustainable will be a critical factor in our planet’s future. It is a matter of the utmost economic, social and environmental importance, and we hope this article has helped illustrate exactly why.

Climate control solutions can play a key role in making this essential industry more viable for the long term. From facilitating the development of CEA settings, to making food processing and storage as optimal as possible, this technology will actively support the food industry’s efforts to become truly sustainable in the coming decades.

Through our specific industry knowledge, extensive range of products and process-driven approach, at Calorex we help our customers across the food industry operate at maximum efficiency, cost-effectiveness and sustainability.

For more information about our agriculture climate control solutions, don’t hesitate to get in touch with our team using the form below.

Related products

Featured insights

Explore the benefits that can be unlocked by installing dehumidifiers outside of a cold store or freezer room.

Important reasons to implement an effective climate control system in your facility

Regulating humidity can save you a whole host of problems

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.