The expert guide on how to heat warehouses and industrial buildings

- Home

- Insights

- Heating insights

- The expert guide on how to heat warehouses and industrial buildings

Responsible for producing and storing a wide variety of products, from pharmaceuticals to raw materials, industrial buildings and warehouses are core to modern commerce.

However, this crucial role can be compromised when the temperatures inside plummet to unsafe or impractical levels.

Below we discuss the importance of heating these spaces, the challenges associated, and why portable heaters are best suited for warehouse and industrial heating.

Why is it important to heat warehouses and industrial buildings?

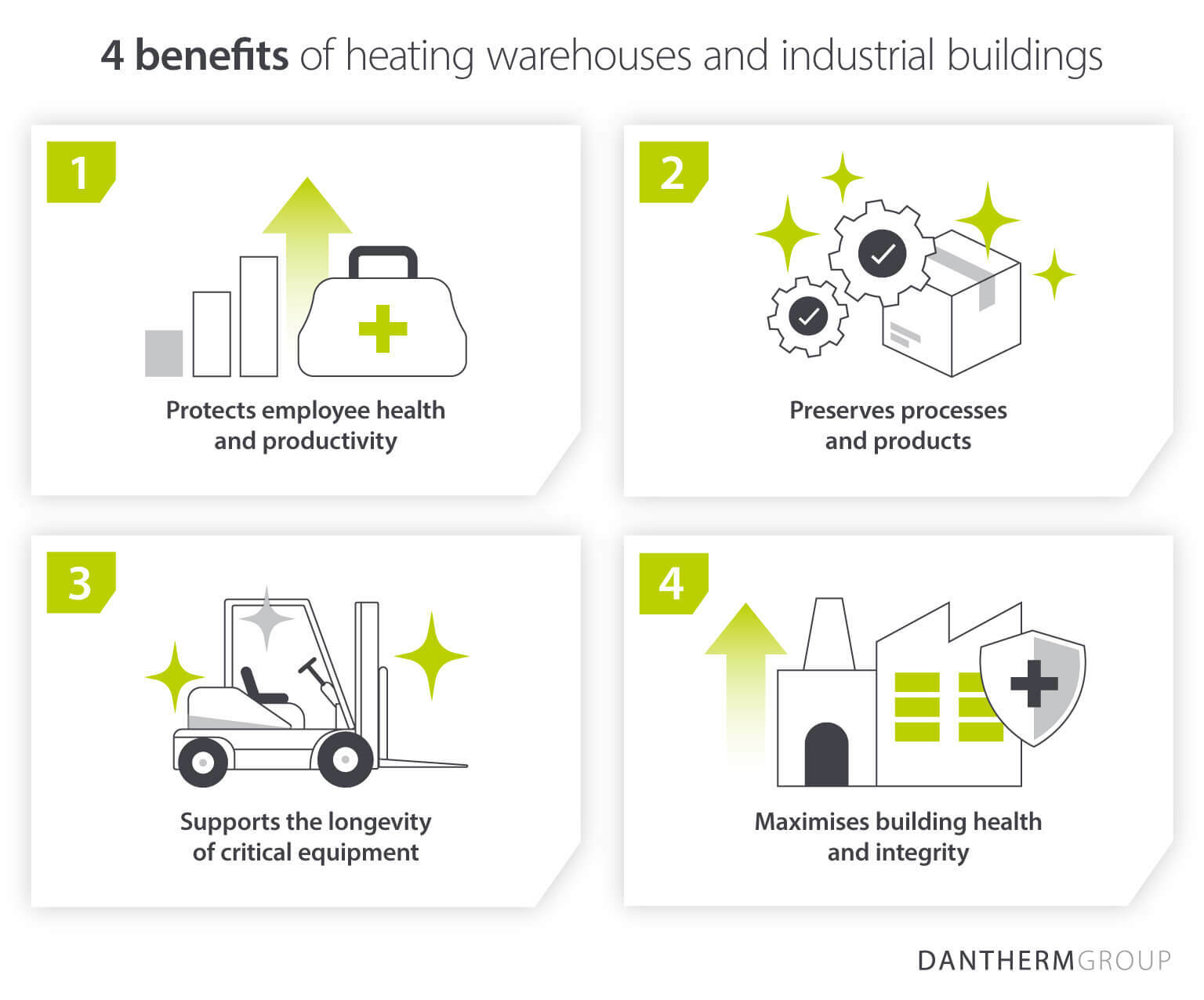

Keeping industrial spaces and warehouses warm and comfortable is crucial. For your teams, your products and your machinery, maintaining ideal conditions during the winter months is key to upholding performance and quality.

First, inadequate interior temperatures create uncomfortable or unsafe environments for employees. At best, this makes routine tasks harder and limits productivity. At worst, it can present a serious health hazard – patches of ice can raise the risk of accidents, while prolonged exposure to the cold increases the likelihood of illnesses.

Because of this, many countries have strict recommendations on legal working conditions. The UK, for example, advises indoor temperatures to be kept at 16°C or above – 13°C if the work involves physical effort. Failing to satisfy a region’s health and safety criteria can result in fines, disqualification or legal action.

Excessively cold temperatures do not only impact employees and their performance, they can negatively affect certain products, such as fruit and vegetables, reducing their shelf life. Metallic items can also begin to corrode when exposed to adverse conditions.

Many warehouse spaces and industrial properties rely on critical equipment to fulfil their duties. And, if temperatures are too cold, systems such as forklifts, ovens and conveyor belts can become damaged or break down entirely, disrupting operations and resulting in costly repairs.

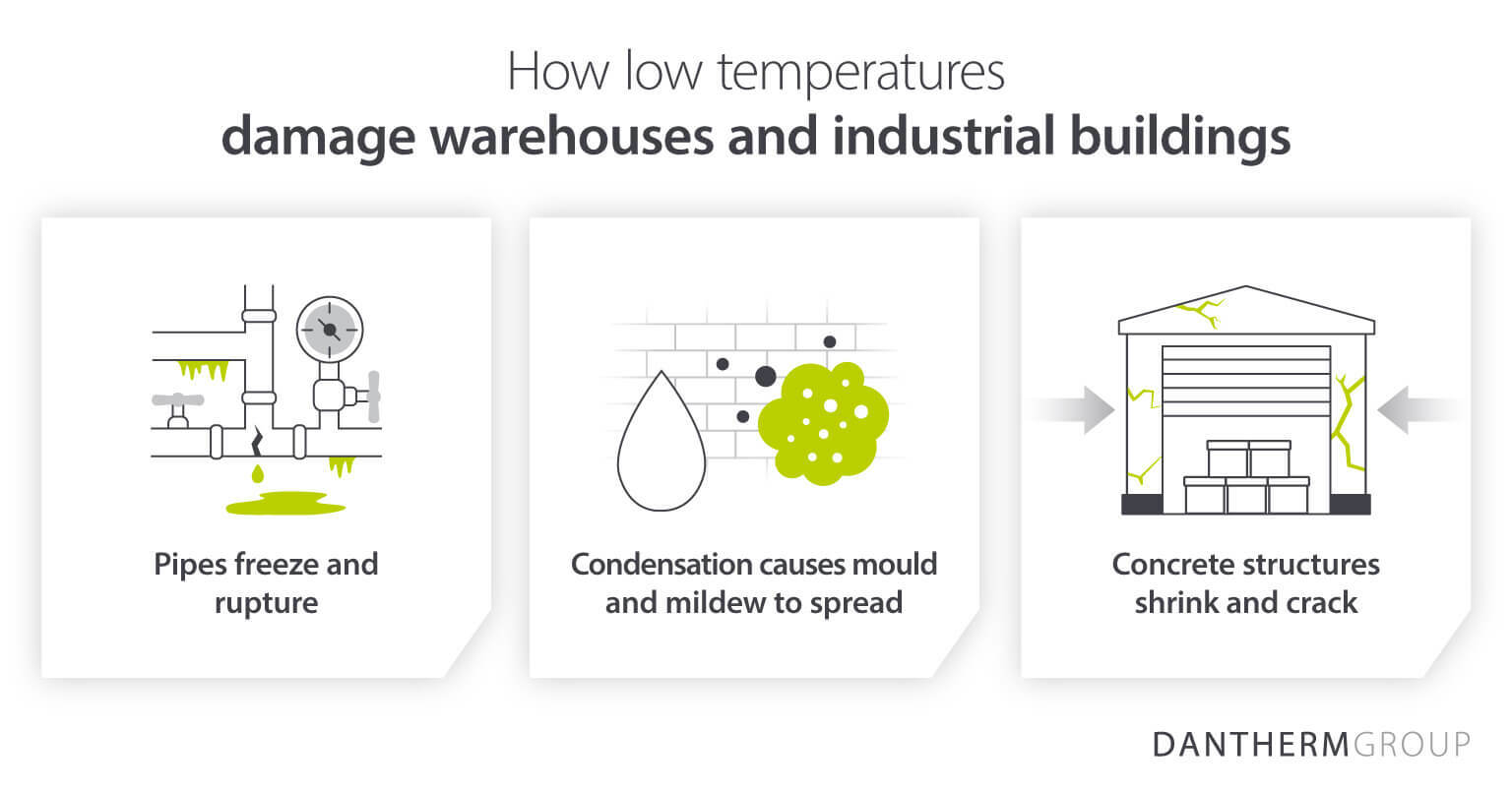

Furthermore, excess cold can damage facilities in a number of ways:

Why is it difficult to heat warehouses and industrial spaces?

Warm air heating is essential to overcome cold warehouses and industrial buildings. However, keeping these spaces at the ideal temperature year-round has its challenges. This is because:

High ceilings trap heat

The average warehouse can be as tall as 14m at its highest point. This presents a problem, as warm air naturally rises, causing pockets of heat to linger near the roof and away from the spaces where it is most needed.

Doors constantly open and close

Warehouses and industrial buildings often have people, items and machinery moving in and out during all hours. When loading bays, doors and windows are opened, warm inside air can easily escape.

These environments have flexible heating demands

Not every warehouse and industrial hall will need consistent temperatures year-round. Often, heat output is required in specific zones, for a certain period of time, adding to the complexity of industrial warehouse heating.

As an example, more heat may be needed in areas with less insulation. Well-insulated spaces, on the other hand, retain this valuable energy for longer.

Warehouses and industrial buildings are getting bigger

The average size of European logistic facilities is increasing. Growing spaces add to the cost and difficulty of warehouse heating, as bigger floor areas need more warm air, as well as dedicated solutions to guarantee even heat distribution.

Industrial spaces are poorly insulated

The EU is home to more than 12 million commercial buildings, approximately 50% of which are over 40 years old. With potentially millions of warehouses and industrial spaces relying on decades-old insulation, warm air may be difficult to retain in these dated facilities.

How to heat warehouses and industrial buildings

Establishing the ideal climate in warehouses and industrial settings is difficult. However, by using professional portable heaters, commercial facilities can unlock a number of key advantages:

Why portable heaters are ideal for industrial and warehouse heating

Although there are many types of conventional warm air systems available, portable heaters stand out as the technology of choice for heating industrial spaces for several reasons:

Portable heaters are cost-effective

As well as being more affordable to purchase than large conventional furnaces and boilers, portable heaters are flexible, and able to reduce running costs by delivering efficient heating where required. They are also simple to service and maintain, further reducing the long-term expenses of ownership.

Heat can be delivered where needed

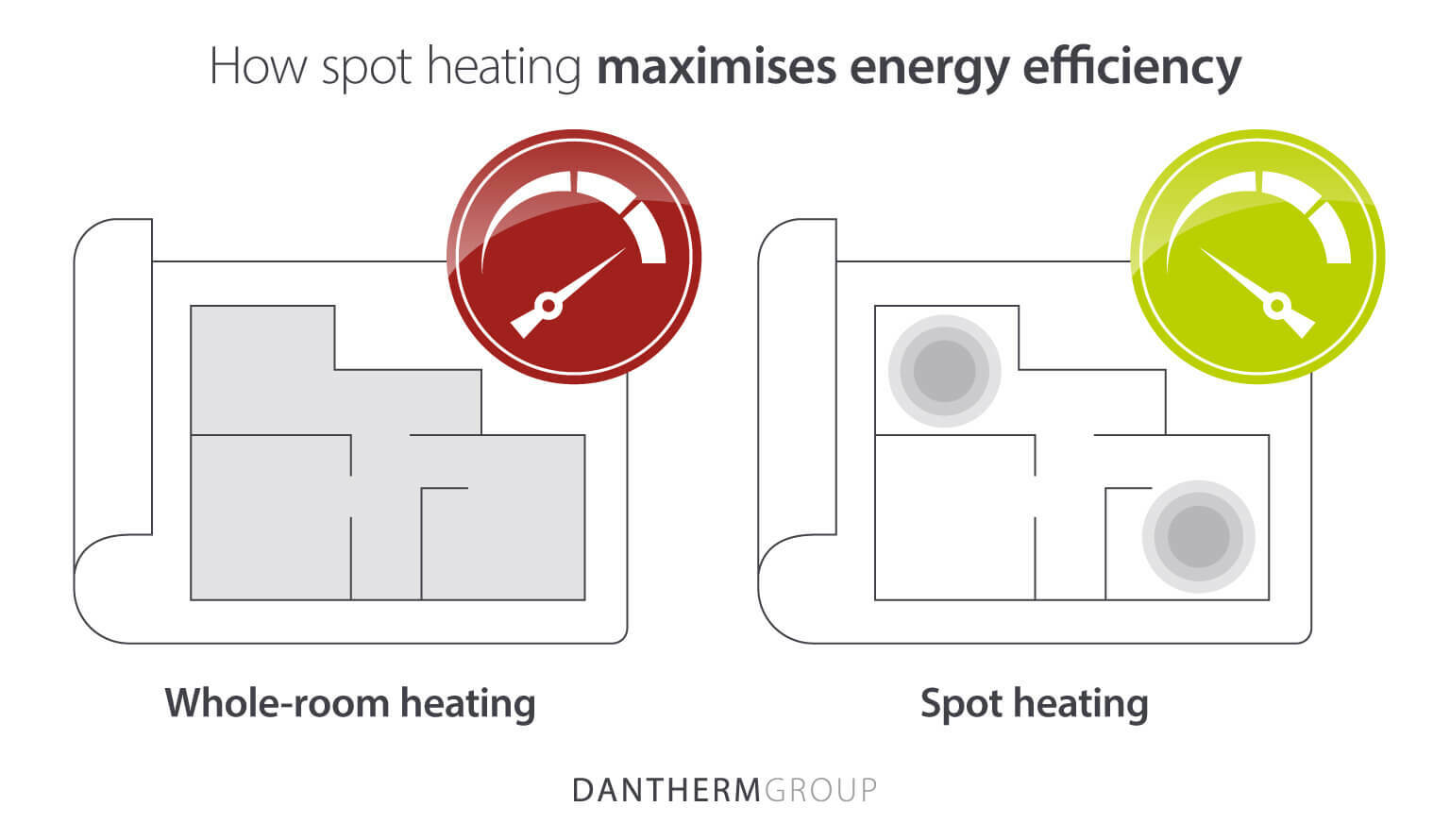

Warehouses and industrial buildings are large spaces. Instead of spending valuable time and money heating every corner of a facility, portable industrial heaters allow businesses to spot heat the areas they need – maximising energy efficiency and comfort.

Systems are instant and easy to use

Portable heaters are not only flexible to deploy, they are easy to set up and use, delivering heat wherever required almost instantly. Plus, no specialist training or qualifications are needed to operate these solutions, allowing heaters to be effectively used by teams either temporarily or permanently.

Units are fit for any application

Gas or oil heaters. Direct and indirect systems. Electric air heaters. Infrared units. Portable heaters are available in a variety of sizes and types, able to suit practically any environment or task – from keeping workers warm during the winter, to protecting critical warehouse equipment from frost damage.

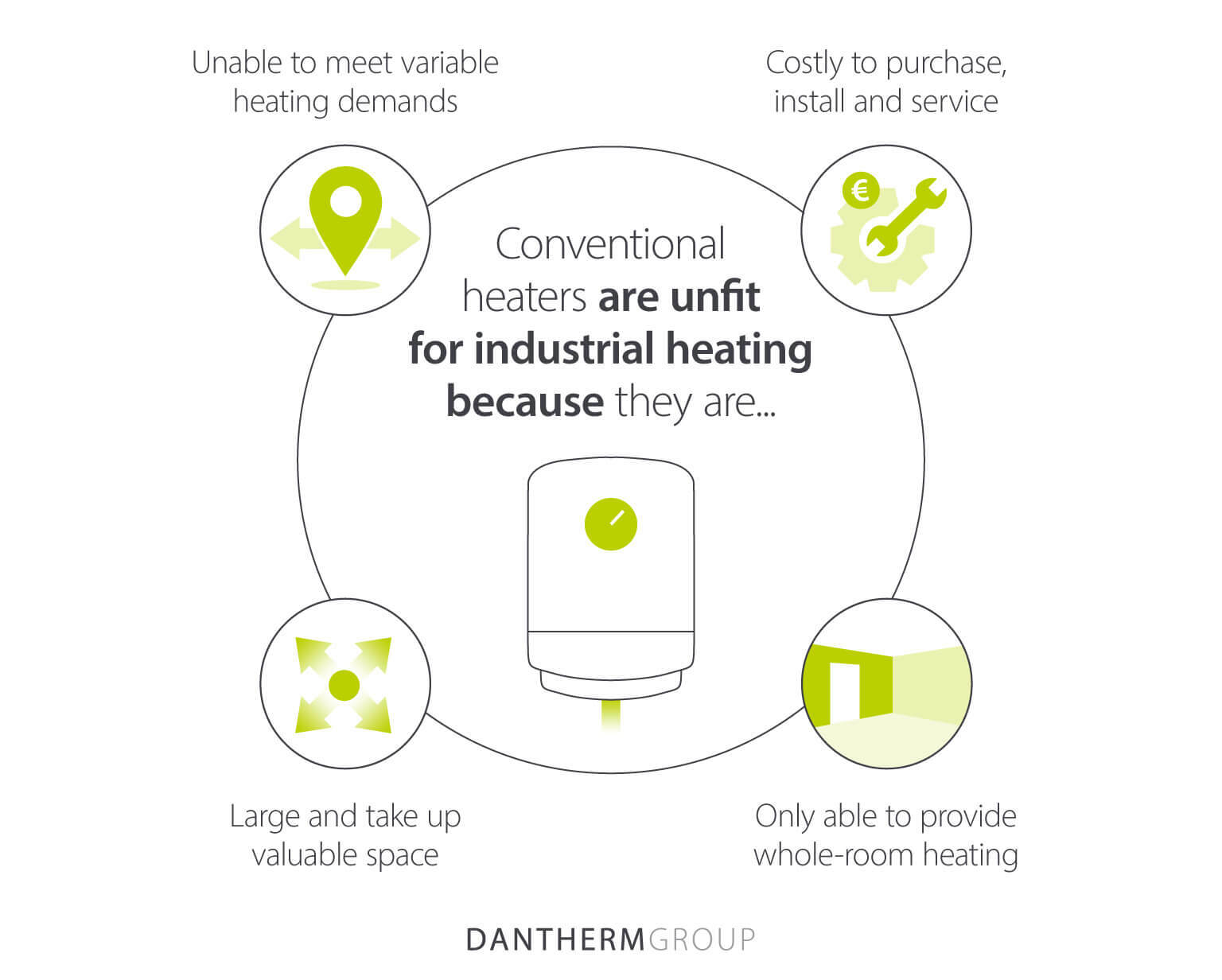

Drawbacks of other heating systems

While traditional heating systems, such as furnaces and boilers, can provide heat effectively, they are not the most practical or cost-effective solution for industrial and warehouse heating:

How to choose the ideal portable heater for your space

Portable heaters are core to efficient and effective industrial and warehouse heating systems. However, not every system will be able to provide the ideal blend of savings and performance you require in your facilities. To select the optimal unit for your environment:

Consider the ideal type of heater

There are several different types of warm air heaters, each of which work in different ways and are suited to separate tasks:

Electric heaters plug into power outlets to produce moderate volumes of warm and clean air, ideal for warming small and medium-sized indoor spaces

Direct gas and oil-fired heaters burn diesel, natural gas or BioFuel to emit large amounts of unclean radiant heating efficiently – great for large, well-ventilated areas

Indirect gas and oil-fired heaters also use combustibles, but produce warm air cleanly at a slight cost to efficiency – ideal for big but less well-ventilated workspaces

Infrared heaters harness electricity or oil to produce vast amounts of radiant heating – useful for spot heating people and equipment

Choose the right sized system

As well as selecting the optimal type of radiant heater, it is also important to consider the heating capacity required. Does a small staff room need warm air? Are there sizeable zones in the manufacturing process that demand high temperatures?

Select a unit able to meet the precise demands of your space. A warm air heating system too small may require multiple units to produce the desired temperatures, reducing efficiency. Conversely a solution that’s too large can overheat spaces, compromising comfort and energy usage.

Speak to the experts

No two warehouses or industrial spaces will need the same size, type and quantity of solution to meet their requirements. To achieve the best performance and savings, it is important to consult trained experts to advise on the devices that will fulfil your goals.

Dantherm Group: European leaders in industrial and warehouse heating

With climate control heritage stretching back to 1954, Dantherm Group is the European leader for efficient, sustainable and durable portable heaters.

We are more than manufacturers of market-leading technology – our support network of advice, spares and technicians makes us the supplier of choice for industrial and warehouse heating projects all over the world.

For help choosing the ideal portable heater for your project, or for more information and advice on heating large industrial facilities, get in touch with our team today.

Related products

Featured insights

Read our crucial introduction to the purpose, benefits and operation of commercial infrared heaters.

High volumes of heat right where you need it and at low cost

Which heating solution is the right choice for your circumstances?

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.