The essential guide to infrared heaters

- Home

- Insights

- Heating insights

- The essential guide to infrared heaters

Discover the capabilities of infrared heaters, how to operate these units safely and efficiently, and the advantages that can be enjoyed with the right solution.

Whether it’s keeping workers warm, defrosting critical equipment or accelerating the drying process on-site, effective temperature control is core to the efficiency of many commercial operations.

Worker productivity can plummet in the cold

Frost can form and damage vital equipment

Slow drying can impact project timelines

However, creating an economical, reliable and efficient stream of heat is often easier said than done with the cost of fuel and energy rising across Europe and around the world.

To establish a dependable heat source indoors or out without breaking the bank, infrared heaters offer a unique type of technology helping commercial entities save energy and minimise running costs.

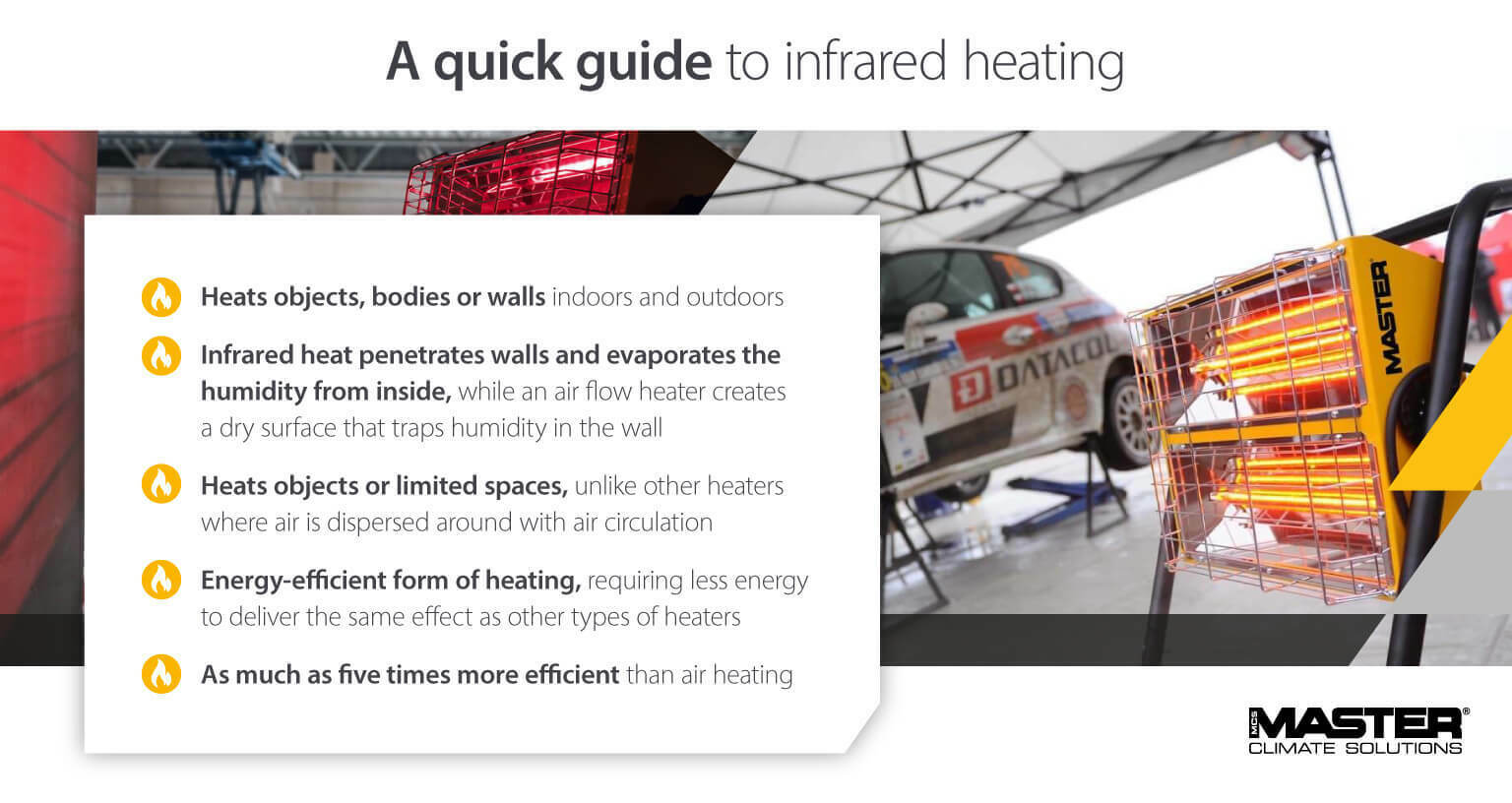

What is an infrared heater?

Infrared heaters harness the power of radiant heat to deliver vast amounts of warmth to precise areas quickly and efficiently.

Unlike more conventional convection heating systems which move the air itself, these types of infrared heaters work by penetrating the atmosphere and warming objects and people directly, much like the sun.

There are two main categories of infrared radiation these types of heaters produce:

Short wave radiation does not heat the air, instead directing all of its heat energy to the objects and people in front of the unit. This process creates no air flow.

Long wave radiation heats up the atmosphere, delivering warmth to the air and surrounding entities. Heat is transferred without moving the air.

As well as the different types of infrared heat, these systems are also categorised by the way they are powered – either by oil or electricity.

How does an oil-fired infrared heater work?

To generate infrared heat, oil-filled heaters such as the DC 61 harness the power of combustion to heat a shield. As the temperature of this panel climbs, the heat the system emits increases.

Although combustible fuels are an effective source of energy, they emit a small quantity of air pollutants such as CO₂, making them suited for use outdoors or in spaces with sufficient ventilation.

How does an electric infrared heater work?

Electric heaters, such as the TS 3A and HALL 1500, work by converting electrical power into radiant heat. To do this, a ceramic heating element is either warmed up, or an infrared light is turned on. This, in turn, emits heat.

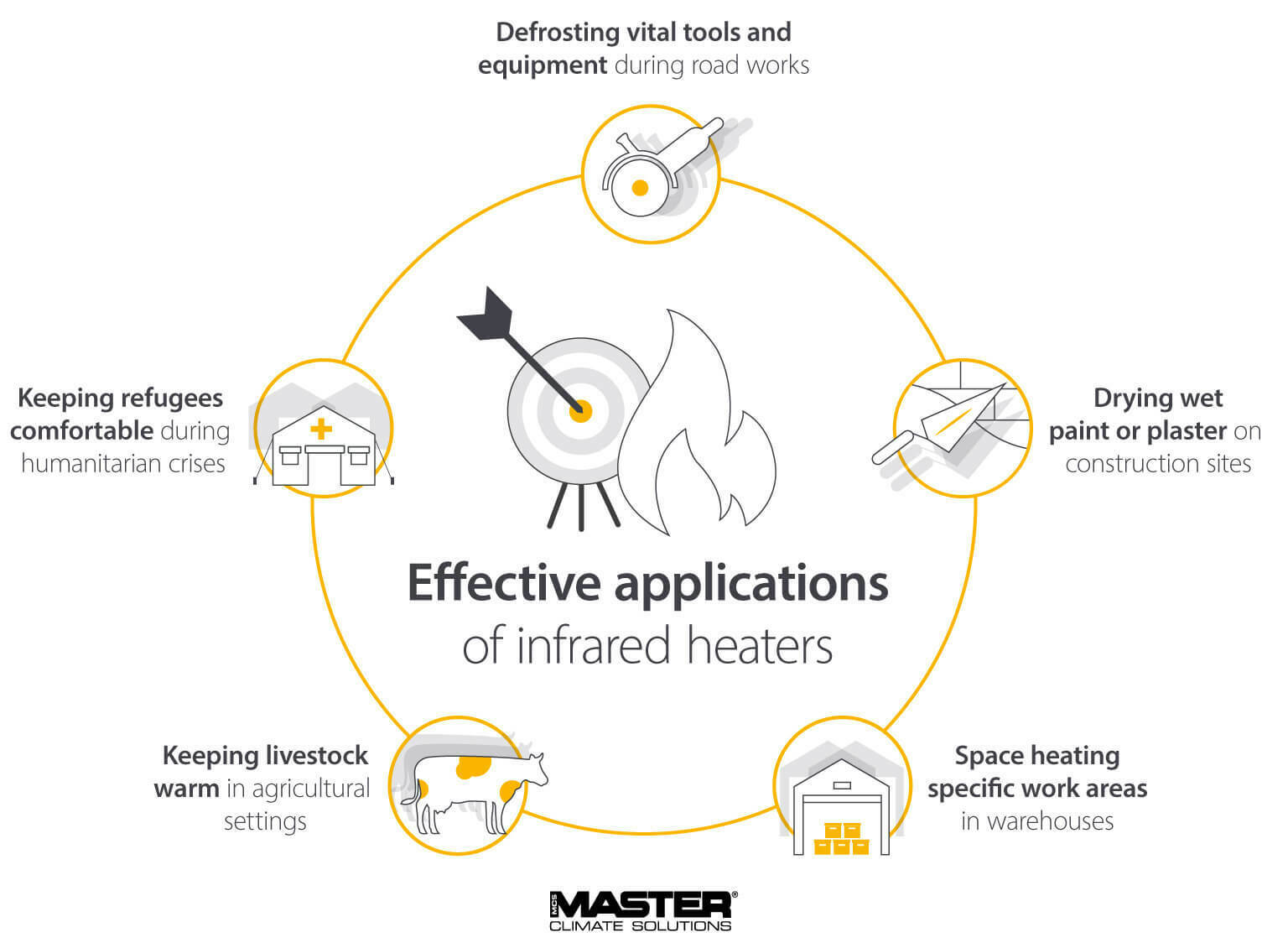

What applications are infrared heaters best suited for?

Because infrared heaters are a unique type of warm air heating system, they are not just ideally suited to space heating, they can be an effective way to warm equipment, dry specific areas and spot heat precise zones. This makes infrared heaters optimal in numerous scenarios, such as:

Why choose an infrared heater?

It is not just the versatility of infrared heaters that makes them the optimal choice for businesses – the unique principle behind these systems offers distinct advantages over more conventional heaters.

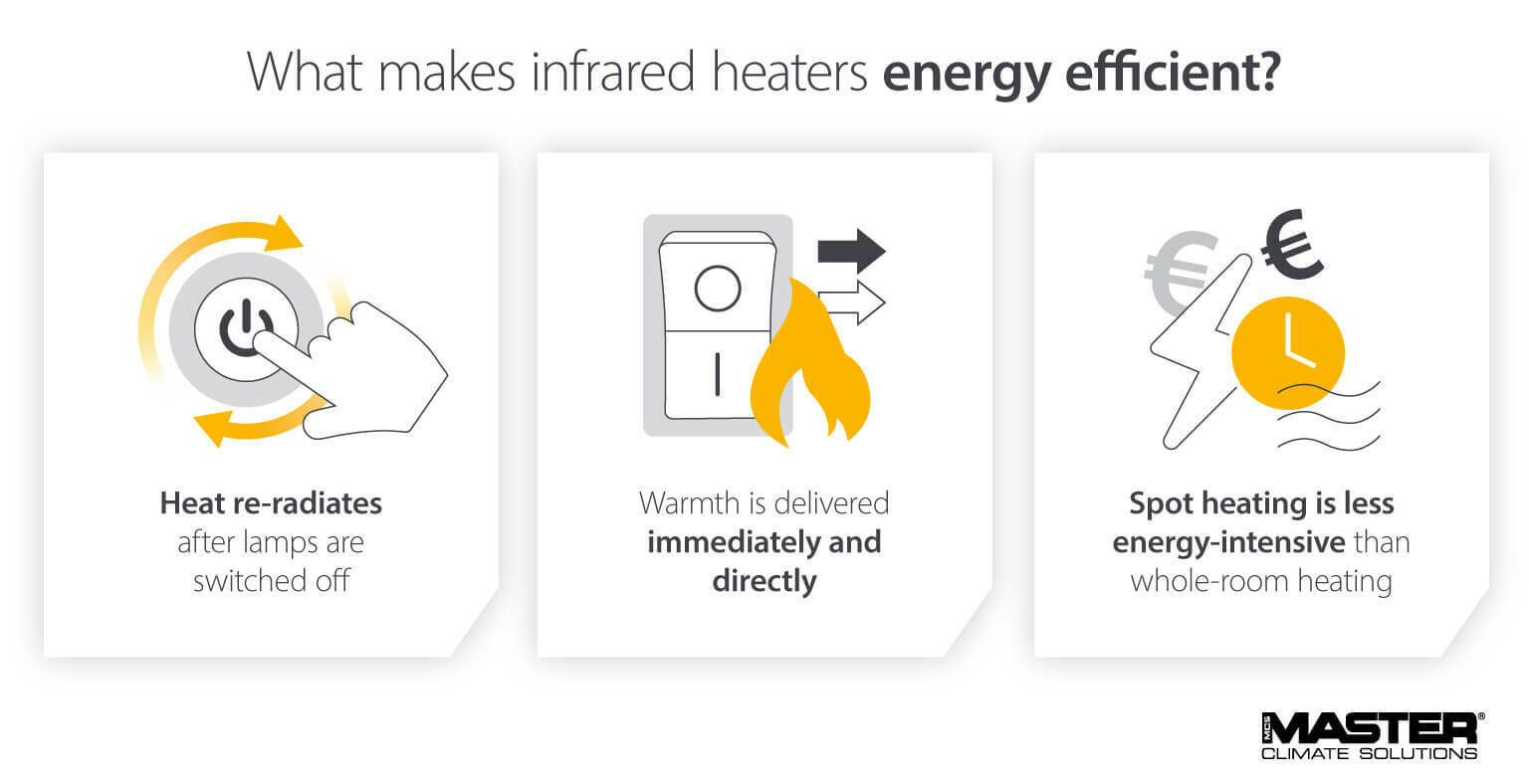

Exceptional energy efficiency

Infrared heaters are able to penetrate the atmosphere and provide warmth directly to people, objects and animals, minimising the energy needed to create comfortable conditions.

As well as being an immediate form of heat delivery, these systems also allow warmth to be re-emitted from heated objects. This helps limit power consumption, as heat energy lingers even when lamps are switched off.

Furthermore, because infrared heaters deliver energy to precise areas, they can double as effective spot heaters. Instead of warming an entire room, the output can be directed to problem areas at a fraction of the cost.

Compact build and high portability

These types of infrared heating systems are also comparatively small in size. In the real world, this is incredibly advantageous as this technology can be deployed flexibly whenever and wherever it is needed most.

The lightweight build and smaller size of these units also make them optimal for use in many environments and scenarios. Whether they must be located on the ground, or elsewhere, infrared heaters are highly adaptable.

Minimal maintenance

Another distinct advantage of infrared heating systems is their robust design and build. With little to no moving parts internally, these types of units tend to be more reliable, creating fewer disruptions to works or services.

As the uptime of infrared units is often high, this also means that the time and resources devoted to machine maintenance can be kept to a minimum, helping reduce their lifetime cost.

Limitations of infrared heaters

Despite providing a range of exceptional advantages, infrared heaters are not the ideal option for every business, site or scenario.

Infrared heaters are inefficient at heating larger spaces, such as entire rooms and buildings

A lack of precise temperature control can make solutions inappropriate for some settings that require exact temperatures

As heat output is focused, these units are not ideal in spaces where people and objects are constantly moving

If infrared technology is not suitable for your scenario, Master heaters cover the full spectrum of heat source technology. From commercial electric fan air heaters to gas-fired solutions, we have a broad range of units to suit any space and requirement.

How to set up and use infrared heaters safely

Although many infrared heaters feature excellent safety precautions onboard, such as overheat protection and anti-tilt switches, there are several considerations to bear in mind when setting up and operating one of these machines:

Commercial infrared heaters can output temperatures as high as 150°C. As a result, it is crucial to keep units at a safe distance from people and flammable materials

Oil-fired infrared heaters emit harmful air pollutants. When using these systems inside, it is essential to establish sufficient ventilation

Radiant heat warms objects and materials directly. To avoid creating an uncomfortably humid environment, avoid heating water sources where possible

When setting up electric or oil-filled heaters, keep cables out of the way to prevent avoidable trips and falls

Securing the unit on even ground can reduce the risk of the unit tipping or falling when in use

To grasp the full scale of safety precautions needed when setting up and operating the various models of infrared heater, it is essential to read the included user manual.

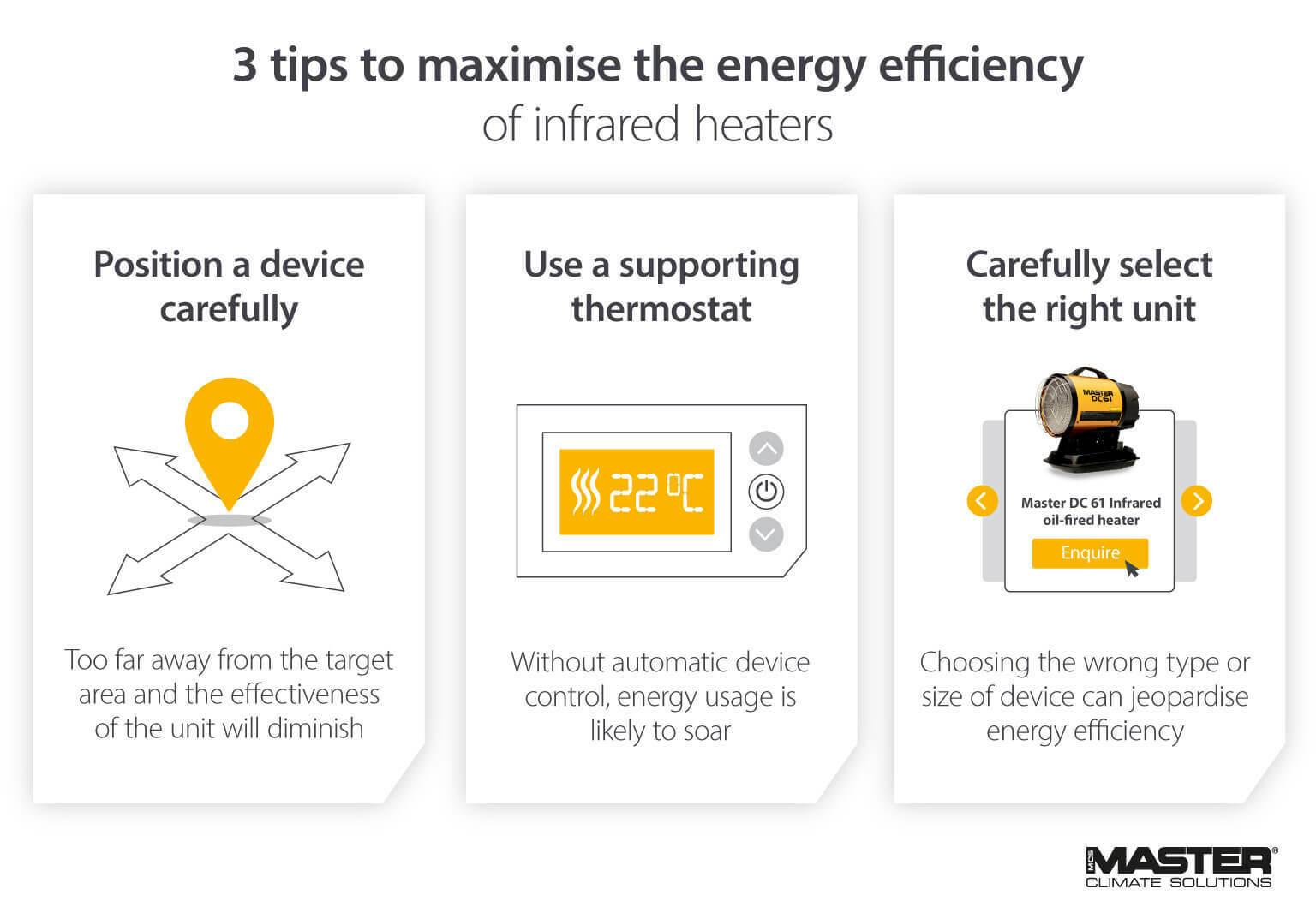

How to maximise the energy efficiency of infrared heaters

Although infrared heaters are exceptionally energy efficient from the outset, the rising cost of energy throughout Europe and much of the world has made maximising every kilowatt crucial. To get the most out of your warm air heating system:

Choose the right infrared heater for your needs

Whether a unit is chosen to dry plaster outdoors, spot heat teams inside or defrost pipework on-site, the role an infrared heater must perform will help determine the size and type of unit best fit for your needs.

Another consideration to acknowledge is the availability of certain power sources. Does your warehouse have a nearby electrical outlet? Can your construction site source enough oil? Understanding what is and is not available will also aid the decision-making process.

Finally, it is important to consider the needs of the workspace. A busy site may prioritise portability, for example, while a factory with pre-set workstations may opt for a larger, wall-mounted heater.

Why Master is the go-to manufacturer for infrared heating

Infrared heaters, in their various forms, are a versatile, efficient and effective source of heat. But, not all solutions are built equally. To drive the best results and maximise energy savings, it is crucial to choose a solution from a manufacturer you can trust.

Master are experts in heating solutions. With over 70 years of expertise, we have not just delivered countless machines to sectors all over the world, we have designed and manufactured a lineup of robust, reliable and efficient infrared heaters.

As well as an unrivalled commitment to quality, Master is the go-to provider for effective and efficient heaters because all of our units are backed by an unprecedented 3-year warranty.

In addition, we can support you with your product post-sale with our exceptional network of advice, spares and technicians, all accessible on the other end of a phone.

To learn more about infrared heaters and which solution is ideal for your scenario, get in touch with our team today, or use the form below.

Related products

Featured insights

Ensure that construction heaters are applied effectively and safely by following this helpful guide.

Become the go-to supplier for construction and water damage restoration

Stay warm for less when working in poorly insulated farm sheds

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.