Preparing and maintaining your portable heaters for the winter season

- Home

- Insights

- Heating insights

- Preparing and maintaining your portable heaters for the winter season

The last thing you want is to enter the coldest months of the year with a portable heater that is broken or ineffective. Here we offer our expert advice to properly store and set up your heater to take on the bitter winter weather.

A chill in the air. Frost at your footsteps. Your breath clearly visible.

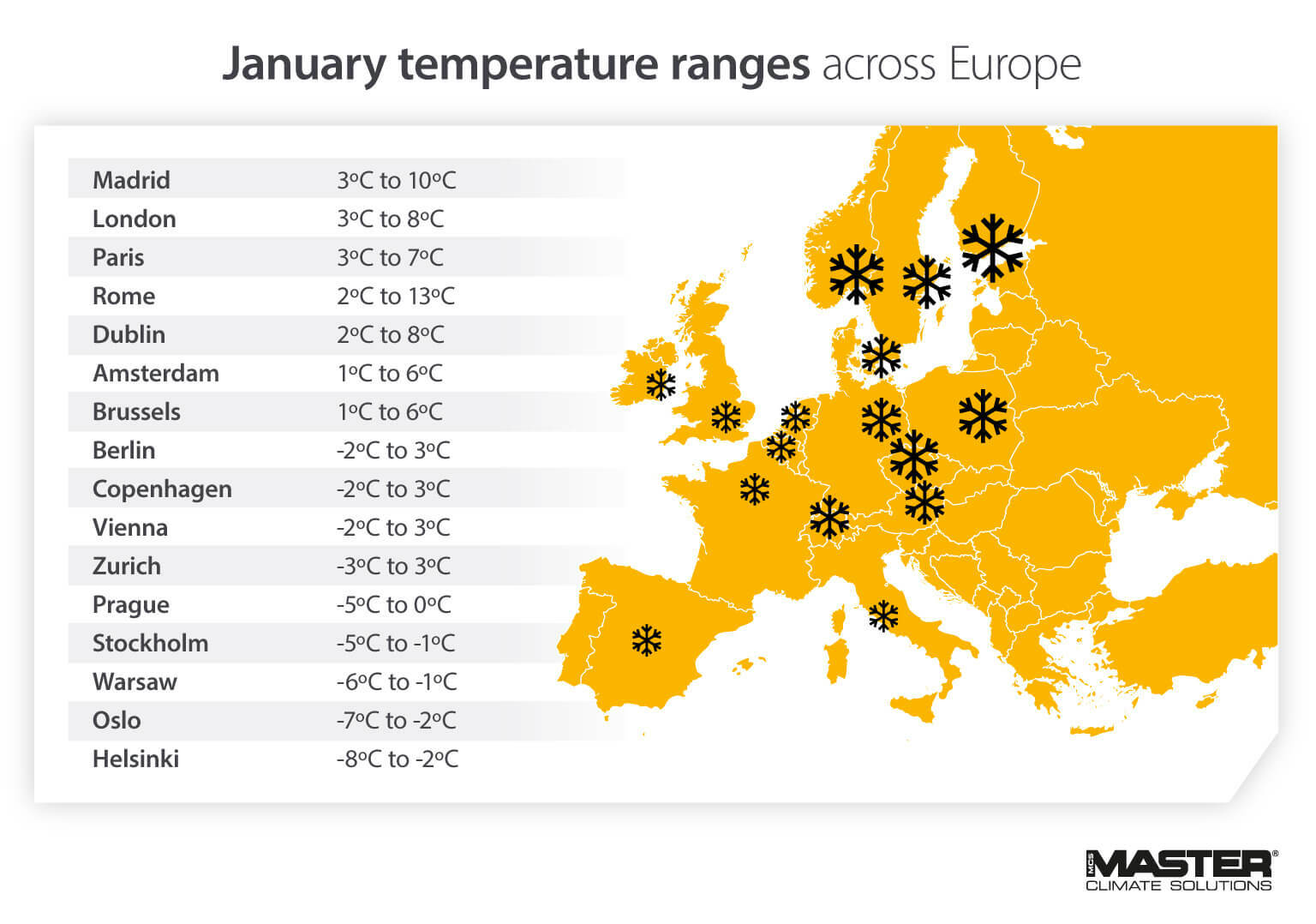

When the winter months arrive, you need heating systems you can depend on. Plummeting temperatures across Europe place a high demand on reliable, consistent heating in all environments – particularly outdoor or spacious settings such as construction sites, factories, warehouses and agricultural buildings.

At Master, our commercial portable heaters help customers across the globe keep the cold at bay, so people, animals and equipment stay comfortable, safe and healthy at all times of year. But to ensure that they receive this much-needed warmth whenever required, it is crucial units are correctly stored, checked and maintained.

Below we outline our essential steps to prepare your portable heaters ahead of winter, so there are no unwanted surprises when you switch them on.

Why is it important that your heater is prepared for winter?

While portable heaters are utilised all year round, they are most heavily relied upon in winter. Temperatures are significantly colder, and consistent exposure to this, especially in open or airy environments, can have serious consequences:

Dangers to the health of people and animals, such as hypothermia

Equipment and devices can freeze or perform inefficiently

People’s motivation, productivity and concentration drop

Heaters combat these conditions and keep temperatures comfortable – but only when they are functioning properly. If you fail to check and prepare your heater prior to the winter months, your risk of breakdowns grows substantially.

This is bad news, as you’ll need to either order a replacement or arrange servicing. This is not only costly, but the waiting times during winter are typically much longer – leaving you, your employees and others in a tough situation until a solution is found.

Our advice for preparing different types of heaters for winter

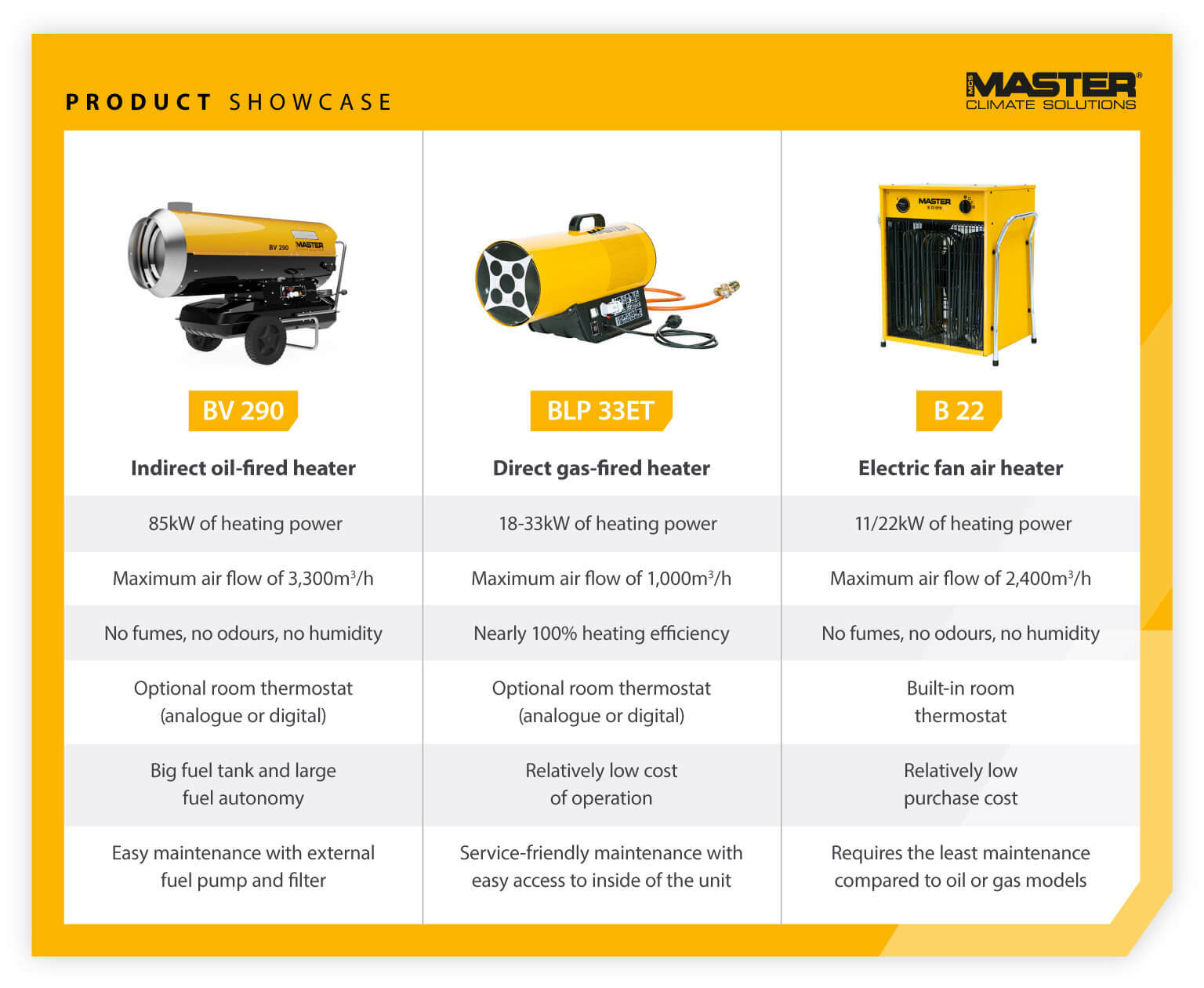

Want to avoid these expensive mistakes? Here are our top maintenance tips to get the three primary types of portable heater – oil-fired, gas-fired and electric – ready for the winter season.

Where to start?

The basis of any service work, irrespective of the type of unit, is to clean dirt from the body of the unit, otherwise, it can impede diagnostics and get into sensitive areas of the unit during service work.

If the appliance has been cleaned after the previous season, but not protected from dust and rain, this must be done anyway.

Oil-fired heaters

Oil-fired heaters use oil-based products, be it diesel or BioFuel, to generate large amounts of heat energy efficiently and effectively.

First, you should always read the operating manual of your specific unit. This will give you important details for preparing, maintaining and operating your portable heater safely, including:

Never use an oil-fired heater in areas with petrol, paint solvents or other highly flammable vapours

Set up and use these heaters in open, well-ventilated areas, with the purpose of introducing fresh air from outdoors

Take care of proper chimney installation to extract the fumes outside

Use dedicated flexible tubes only with indirect oil heaters designed for air ducting

Avoid fire hazards by placing the hot or functioning heater on a flat, level surface

Revisiting the manual every time you use a heater helps guarantee you are using it as intended, and are never leaving anything to chance. After this, there are several important checks you should perform:

Check the power supply wire is not broken or damaged

Check for dirty filters (output, intake, fuel, etc.) and either clean or replace these if necessary – we would advise cleaning or replacing filters at least once per year

Review and clean the fuel tank at least once a year ahead of the winter season

Check the condition of the nozzle, combustion chamber, heat exchanger, electrodes and other components for any signs of damage or wear

Finally, you will want to test the heater in late summer or early autumn. This gives you time to address any issues you spot and perform proper maintenance work before the rough winter weather arrives.

Gas-fired heaters

Gas-fired heaters also use fuel to generate heat energy, but instead utilise canister gases to produce this, such as propane-butane mixtures.

Once again it is advised to read the operating manual. This not only gives you specific guidance pertaining to a heater, but also important advice for safe operation, such as:

If you smell gas, switch the heater off immediately, close the gas cylinder, disconnect the mains plug and contact aftersales assistance

Always position the gas cylinder in a protected position behind the appliance – the heater should never face the cylinder

Ensure the heater has access to a continuous supply of fresh, outdoor air – good airing is supplied when the room volume is measured against heat capacity, using the formula of 1m3 for every 100W of power

Once you have reviewed the manual and taken any necessary actions, you should then proceed to:

Check the power supply wire is not broken or damaged

Check for dirty filters (output, intake, fuel, etc.) and either clean or replace these if necessary – we would advise cleaning or replacing filters at least once per year

Check the tightness of fittings with soapy water – if any bubbles are formed around a fitting, this indicates a gas leak

Fit appropriately sized gas cylinders – 30kg cylinders are recommended up to a heating capacity of 33kW, and over this level you will need to use cylinders with greater capacity

Using the right-sized gas cylinders is crucial to optimal performance. If there is a lack of gasification of the fuel, your heater will not deliver the heat output expected. If you need help determining what size cylinders to use, consult the operating manual or speak to an expert.

Again, it is recommended to test the heater in the weeks and months prior to winter to give you time to identify and resolve any problems.

Learn more about the differences between oil-fired and gas-fired heaters.

Electric heaters

Electric heaters do not require any additional fuel source to generate heat energy beyond access to a nearby plug socket.

Start by consulting the operating manual for any unique guidance and to review important safety rules, such as:

Ensure the heater is supplied from an electricity source that matches the requirements specified on its rating plate

Only use a feeder cable that includes the earth lead to avoid electric shocks in an emergency situation

After this, you will simply need to test whether your portable electric heater is working by plugging it into a suitable mains socket. During testing, take note of the following:

Is it generating the expected amount of heat energy?

Are its heating elements warming up evenly?

Does the heat output cover the whole intended area?

Do you smell any indication of burning?

Is the power supply cable damaged in any way?

The burning smell is important to check for as this can indicate burnt electrical components that should be repaired or replaced, such as relays, contactors, motor windings, connectors and wires.

How should you store heaters before winter?

Effective year-round storage for your portable heaters is just as essential as these pre-use checks. If your heaters are kept for months at a time in an inappropriate location or without taking necessary precautions, this can significantly raise the risk of units being unfit for work when the winter season rolls around.

Fundamentally, you want to store all portable heaters in a dry place that is safe from rain, snow and other external elements. Dry conditions are critical as high humidity or consistent exposure to moisture can have a major impact on their performance:

Corrosion causing components to rust

Moisture damage to electrical components

Formation of sediments in fuel tanks

In addition, it is advisable to ensure that any fuel is removed from oil heaters before they are placed in storage during the warmer months. Any fuel that is left behind can cause damage to components, as well as present an avoidable safety risk in cases of fire.

Should you have heaters serviced and checked by professionals?

If during your inspections or testing you notice any damage or issues with your portable heater, it is important that they are treated at an authorised service centre by specialised personnel.

Remember – user interference during the warranty period for any heater can result in this being voided. Plus, you want to make sure the source of any problem is found and resolved by a trained technician, rather than risk an incomplete or unprofessional job.

Our specialist engineers and support network at Master can provide expert guidance if you identify any issues with your portable heaters. We can conduct any required maintenance work and point you in the direction of the nearest suitable spare parts.

Why Master heaters are trusted worldwide

We hope you find our preparation, storage and maintenance tips for portable heaters useful. During the coldest days of the year, you never want to be let down by your heater, nor face the consequences this will have on people's health, comfort and performance.

But even more than a good approach to preparation, you need to be backed by quality products. Master heaters are designed in accordance with the needs and suggestions of both our customers and service professionals, meaning our solutions are well-thought-out from a maintenance perspective.

Our entire range of oil-fired, gas-fired and electric heaters represents decades of precise engineering and robust manufacturing, to ensure that our units generate effective, efficient heating whenever called upon.

Alongside our wide choice of commercial portable heaters, Master also delivers:

A well-developed network of service points

Exceptional after-sales service

3-year limited warranties

Spare parts available for at least 10 years

For more information about our unrivalled heating systems, get in touch using the contact form below.

Related products

Featured insights

Discover how to choose the most appropriate heating solution for your construction project.

BioFuel is here – are you ready for change?

Become the go-to supplier for construction and water damage restoration

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.