Oil-fired vs gas-fired portable heaters for construction sites

- Home

- Insights

- Heating insights

- Oil-fired vs gas-fired portable heaters for construction sites

In this article, we discuss the differences between oil-fired and gas-fired portable heaters, where each type is most suitable, as well as the benefits and drawbacks of each type of unit.

Construction is a year-round responsibility. Even when conditions are wet, or the cold weather arrives, building work pushes on to keep teams on track and projects on schedule.

To create a productive, comfortable and warm environment for workers, many building sites utilise direct-fired gas and oil heater units. However, it is not just employees that need heat to work effectively – machinery and materials can freeze overnight and be rendered unusable until defrosted.

To meet the precise needs of your operations, there is no ‘one-size-fits-all’ heating solution. Throughout this article, we aim to give you all of the information you need to make the right purchase.

What is a gas-fired portable heater?

A gas-fired heater is a type of device that burns canister gases, such as a propane-butane mixture, to generate a large amount of heat energy efficiently and effectively.

While the byproducts of gas combustion, CO2 and water, have a moderate impact on the environment, the moist air pumped out is not ideal for drying construction materials, such as wet concrete or fresh plaster.

What is an oil-fired portable heater?

An oil-fired portable heater works similar to gas in that it burns fuel to generate heat. However, the type of combustible used is different – instead of gas, these units use oil.

As well as being more expensive, the byproducts of oil combustion – CO2, trace amounts of CO, sulphur and nitrogen oxides – have a greater impact on the environment. Despite this, these heaters are ideal for improving drying processes, as the hot air produced contains fewer water molecules than LPG or natural gas fuels.

Furthermore, indirect-fired heaters generate completely dry air, as these keep warm air and combustion products completely separate.

Why are these units ideal for construction work?

Direct oil and gas-fired heaters are ideal for construction sites as they are often portable, meaning they can be positioned wherever needed. As well as that, the energy produced by burning these fuels is considerable – even a small unit can produce enough heat to warm an area large enough to carry out work.

While electric heaters are better for the environment and produce no harmful byproducts, the smallest 230V outlet commonly available on-site can only power a 3.3kW unit.

On the other hand, a gas or oil heater can use the same electrical outlet to power the fan and controls. This means they have the ability to generate much more power from the chemical energy of the fuel used – in the case of Master heaters, this can be anywhere from 10kW up to 225kW.

The differences between direct oil and gas-fired portable heaters

When considering what type of temporary heating device is ideal for your worksite, it is important to understand the applications each technology is best suited to. Reliability, performance and cost-effectiveness are also factors that will influence which choice is best for you.

Oil vs Gas: Cost-effectiveness

Construction projects are large, complicated jobs with potentially thousands of moving parts. With so many facets to manage, how do you ensure work remains within budget? One way you can do this is by minimising the costs associated with day-to-day operation.

Direct gas heaters are often more cost-effective to run when compared to oil heaters, as the fuel itself is sold at a lower cost. Additionally, because these units are simpler in construction, the buy-in is typically smaller than that of an oil alternative.

As an added benefit, the output of a gas heater can be adjusted with a valve. Variable power allows one unit to be adapted to smaller and larger spaces and avoids the excessive heating costs that occur with oversized units. In the case of our BLP 103ET heater, the power can range from 57kW to 103kW

Alternatively, while oil-fired heaters are more costly to purchase and operate, oil is more commonly used for other machinery on construction sites. As a result, this fuel may be more readily available to power your heating units, making this an overall more cost-effective option compared to acquiring gas canisters for use exclusively in your heaters.

Oil vs Gas: Applications

As construction sites develop over time, the needs in relation to workers and construction also change. A direct-fired or infrared heating solution during Phase 1 of a project may not be suitable for Phase 2.

Direct oil-fired heaters produce warm air together with the products of combustion, so they have an efficiency close to 100%. This makes them ideally suited to drying wet construction materials, like plaster, concrete and for other places without restrictions, due to either people staying there, or specific materials that can absorb foreign odours.

For use in enclosed spaces, an indirect oil-fired heater is essential because these units prevent the emission of CO2 and other harmful byproducts of these combustible materials.

Conversely, gas-fired heaters (which in the construction industry are almost exclusively available as direct-fired) produce warm, but moist air. While not ideal for drying, these units produce heat at almost 100% efficiency, making them an optimal solution to keep some materials warm and workforces comfortable.

However, because this fuel is highly flammable, colourless and heavier than air, LPG or natural gas heating units cannot be used underground for health and safety reasons. In these situations, an indirect oil-fired heater will often be the most practically suitable.

Oil vs Gas: Reliability and maintenance

On construction sites, workers rely on critical equipment to do their job. But, when disaster strikes and machinery breaks down, delays can quickly snowball and disrupt existing timetables. To avoid costly stoppages, a reliable heater is needed.

More often than not, direct oil-fired heaters are made of more components, and this may negatively affect reliability, as more components increase the likelihood that a piece of equipment could break down. When it does come time to conduct maintenance on your oil heater, the added complexity may increase the expertise and time required to keep units operational.

Gas heaters, on the other hand, are typically simpler systems. With fewer moving parts, there is less chance for individual parts to break down and cause issues. In addition to this, the basic construction could expedite maintenance when it comes time for an inspection.

Oil vs Gas: Performance

While the performance of both types of units is largely similar, there are a number of other related considerations to bear in mind for each type of technology.

Direct oil-fired heaters are more complex machines – these additional pumps, filters and fuel tanks add extra weight to these units. While still man-portable, the heavier oil-filled heaters rely on wheels to move around. This may limit the flexibility of larger units of this technology – especially up and down flights of stairs.

Conversely, gas heaters are simpler and lighter as the fuel cylinders are supplied separately. This means that units can be picked up and transported with a handle – suitable for sites full of rugged terrain. Despite this, it is important to remember that larger gas tanks - or more aggregated gas cylinders – are needed for powerful heaters in order to prevent them from emptying too quickly and freezing.

Other heating factors to consider

Although both types of construction heaters have their own advantages and drawbacks, there are a number of other factors to consider when deciding the right solution for your worksite.

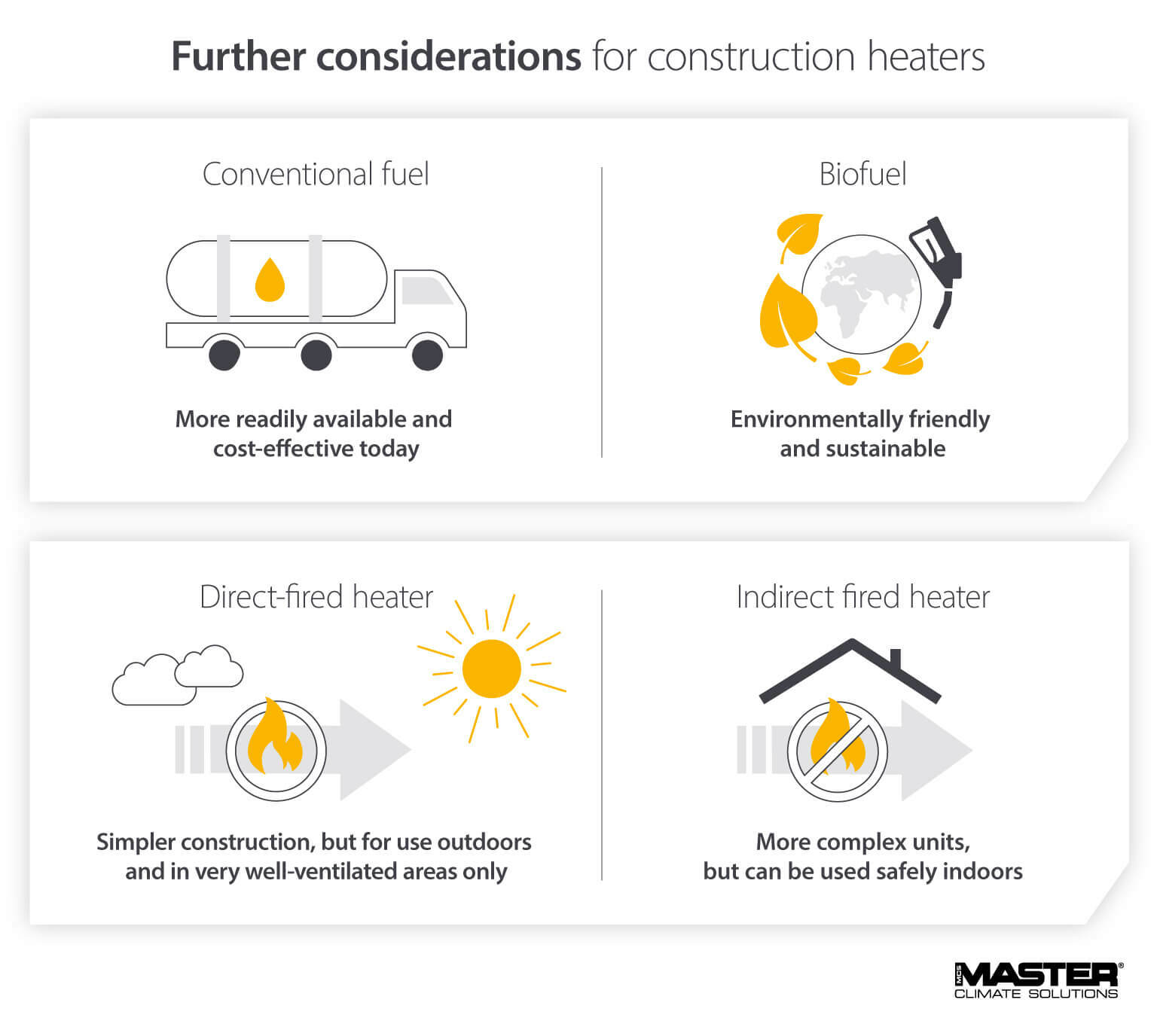

Direct or indirect fired heaters?

Both oil and gas-fired heaters come in direct and indirect variants. To ensure you are operating safely and effectively, it is important you choose the right type of unit.

Both types of heaters need a sufficient supply of fresh air for a proper combustion process, which consumes oxygen from the air.

Additionally, the hot air produced from direct-fired heaters contains all of the products of combustion, such as CO2. Although this is perfectly suitable for use outdoors, and in well-ventilated areas like shell buildings, the build-up of harmful pollutants indoors can make employees feel unwell.

Indirect-fired heaters, on the other hand, separate warm air and combustion products through a heat exchanger and chimney. Therefore, hot air pumped out is pollutant-free - ideal for use indoors.

It should be noted that gas-fired indirect heaters are rarely found on construction sites, due to the higher safety requirements associated with gas fuel.

Biofuel or conventional fuel heaters?

As a growing number of countries aim to reduce their carbon footprint, strict new regulations are emerging that may prohibit the use of certain fossil fuels in the coming years.

In response, at Master we are beginning to embrace sustainable new fuels, such as HVO 100, by launching a new hybrid range in 2022 that can use both conventional and eco-friendly fuels. From 2023 onwards, our range of heaters will pivot to use only biofuels.

With imminent change looming, ensure you are making the right purchase to future-proof your investment.

Total site heating or spot heating?

The size of the area you need to heat is another factor to consider before deciding on a particular heater. If you need to heat a large space, a more powerful unit, such as the indirect-fired oil heater, BV 290 (capable of delivering up to 85kW heating power), will be necessary to ensure the temperature is well-maintained.

However, if you only need to keep specific spots well-heated, such as to dry a plaster wall or provide a comfortable resting space for workers in a large space outdoors, an oil-fired infrared heater like the XL 61 (17kW power) can deliver heat fast and exactly to where it is required without any air movement. This can be more energy-efficient depending on your on-site needs.

Which type of heater is best suited for me?

We hope this has shed some light on the key differences between oil-fired and gas-fired heaters, the roles they are best suited to, and the benefits and drawbacks of both. With this information to hand, you can help make an informed decision for your next project.

Master are perfectly positioned to deliver effective, sustainable and portable oil and gas-fired construction heater units. No matter the weather, our solutions can work to improve your experience for staff on-site at a lower cost to both your bottom line and the environment.

Construction projects around the world trust Master as a reliable manufacturer because our range of gas and oil heating systems are:

Easy to operate

Construction sites are a melting pot of expertise, knowledge and backgrounds. To ensure anyone can safely and effectively operate our heaters, we have designed our range of heating solutions, such as our BLP 33ET, to be as easy to use as possible. The heater does not require complicated configuration - everything important is explained with clear pictograms - just plug and play.

Because building projects are so large and complex, reducing the time wasted configuring heaters saves your team valuable time. Although a few minutes every day seems negligible, this can quickly build up, especially over the course of several years.

Built to last

We understand how important reliability is to the profitability of your operations, which is why our construction heaters are built with high-quality materials throughout. Units, like our B 100, come fitted with a stainless steel combustion chamber, as well as a thermally protected motor, to extend the operational life of your unit for years to come.

By creating products built to operate in and withstand rugged environments, we aim to reduce costly downtime on-site. As an added benefit, longer-lasting products allow your organisation to get more value out of every purchase, boosting your return on investment.

Backed by a unique 3-year limited warranty

Lastly, even though our temporary heaters operate within harsh construction environments, we still offer a 3-year limited warranty on all Master products. This keeps our customers protected in the unlikely event our heaters encounter an issue.

If you want to learn more about our full range of heating solutions, get in touch with our team today using the form below. Our experts are ready to help you find the ideal solution for your needs.

Related products

Featured insights

Flooding is inevitable in winter. Learn how portable heaters can help speed up the drying process of affected buildings when outside conditions are at their worst.

Become the go-to supplier for construction and water damage restoration

High volumes of heat right where you need it and at low cost

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.