Lower your building’s carbon footprint with Biocool

- Home

- Insights

- Cooling insights

- Lower your building’s carbon footprint with Biocool

In industrial and commercial buildings, climate control is essential for keeping temperatures at a safe and comfortable level for staff and visitors. But with tighter regulations, government pressure and better environmental awareness from consumers, we are at a critical time for companies to be investing in eco-friendly solutions. In this article, we’ll be explaining why evaporative cooling is the answer.

Due to the unique types of building, interior configurations and purposes, implementing the most efficient climate control methods in commercial and industrial spaces comes with unique challenges and extra considerations, including cost, safety, practicality and sustainability. For example:

Food production requires hygienic, well-circulated air. Particularly in bakeries, where heat from ovens needs to be counteracted without affecting other processes.

Automotive production is already high in energy consumption and reliant on having space for large machinery and carefully planned production lines. The cooling solution needs to be both cost-effective and unobstructed to production.

Laboratories require highly-controlled environments to ensure the safety and effectiveness of their products. Cooling systems are an integral part of this, and must not introduce contaminants from outside or from other areas of the building.

Plastic and glass manufacture both include heat-intensive processes that require high-capacity cooling. For staff safety, these types of facilities also need to be well-ventilated to expel dust and chemicals from workspaces.

Shopping centres and hotels are responsible for ensuring visitors enjoy a positive experience. The ability to maintain a comfortable climate with fresh clean air will have a significant impact on their revenue.

Gyms can quickly become hot and stuffy, especially in peak hours. Without adequate cooling and ventilation, high temperatures are a hazard.

What are the problems with traditional air-conditioning methods?

While traditional AC can be appropriate in smaller enclosed spaces, like homes and offices, they are often ineffective, inconvenient or unsuitable for the configuration of the types of building commonly found in the commercial and industrial sectors.

While every cooling solution should be unique to its environment in order to achieve maximum efficiency, a traditional AC system will fall short in commercial and industrial buildings for the following reasons:

Energy efficiency

For air-conditioning to be effective, spaces need to be well-sealed. The loading bays of warehouses, large doors and windows that are constantly opening in factories or entrances to shopping centres with high footfall mean cool air will quickly escape, requiring more energy to replace.

Practicality

More so in industrial spaces, the ducting and installation required for fixed air conditioning units can take up space that is required for working areas, storage, machinery or vehicles. In the case of commercial buildings accommodating visitors, cumbersome vents and ducting can affect their experiences and the presentation of carefully designed building interiors.

Environmental impact

Especially in a building where heat-intensive processes are being carried out, a high cooling capacity is needed in specific areas. The hotter the environment, the more energy is required for an AC unit to achieve a safe and comfortable temperature.

Global warming

Air-conditioning units already use a lot of electricity when running constantly at a high capacity. In addition, units that use refrigerants contain chemicals that absorb heat from the environment. As these turn from being a cool liquid to a gas, and then back to a liquid, heat is released outside. In older units using CFS gas, this has a significant effect on global warming. Over 200 countries have signed an agreement to ensure that these units are no longer produced.

Reliability

Technical systems and complex ducting means that replacement parts and repairs can be both costly and time-consuming. Plus, the consequences of a refrigerant leak will also have a significant impact on the system’s carbon footprint.

Environmental regulations worldwide, including The European Green Deal, are putting more pressure on companies and property owners to invest in efficient cooling methods for their facilities. For many, this will mean a move away from traditional mechanical cooling systems and towards cleaner technologies.

What’s the alternative?

Evaporative cooling units rely on scientific principles that were developed thousands of years ago and have been integrated with state-of-the-art technology for modern applications.

To achieve its exceptional environmental friendliness, evaporative cooling uses the natural process of evaporation to lower the temperature of indoor, outdoor and partially open spaces. Here’s how it works:

As water evaporates, particles with the highest energy leave the moisture first, leading to a drop in temperature. Evaporative cooling systems take advantage of this natural process to cool down a space:

A fan draws hot dry air across cooler pads which absorb water from a reservoir.

When the hot air crosses the cooler pads, the water molecules on the surface evaporate and lower the air temperature inside the system.

This fresh air is circulated around a building, forcing hot stale air outside.

What makes evaporative cooling units so environmentally friendly?

The hotter the environment, the higher the capacity

Because evaporative coolers use warm air to harness the cooling power of evaporation, they have a higher cooling capacity as the temperature increases - increasing their ability to cool without using extra energy.

Zero CO2 emissions

Because just a blend of air and water is used by evaporative coolers to lower the temperature, no CO2 is emitted from these units.

Lower energy consumption

Electricity is only needed to power a pump and a fan, which means evaporative cooling units consume 80% less energy on average than conventional air conditioning systems.

Less wasted cooling

Without the need for vents and ducting, portable evaporative cooling units can be more easily placed in the areas where they are needed most, instead of wasting energy cooling empty spaces.

Less invasive installation

With a relatively simple construction, evaporative cooling units are quick and easy to install in comparison to complex mechanical units. And, in the case of mobile units, no installation is required at all.

Zero waste

Since no chemical treatment of the water is needed to cool the air, the water inside the unit can be reused, generating zero waste and minimising the environmental impact.

Cleaner air

Instead of recirculating stale air, evaporative cooling units maintain their efficiency while the space is kept 100% ventilated. This helps remove particles, dust, microorganisms and odours from the atmosphere.

For some context on how the benefits of evaporative cooling compare with traditional air-conditioning systems, the table below shows a comparison between a Biocool evaporative cooling unit and a standard AC in a 3,000m² warehouse in Madrid.

AC | BIOCOOL | ||

ENERGY CONSUMPTION PER YEAR | 224,400 kWh | 29,040 kWh | |

TOTAL CO2 EQ EMISSIONS (TON) PER YEAR | 156.98 | 10.16 | |

- Savings in electricity costs € compared to AC: €19,536/year; -87%

- Reduction of equivalent CO2 emissions: 146 Ton CO2 Eq/year; -93.56%

Further evidence of the environmental benefits of evaporative cooling over air conditioning across large industrial spaces can be seen in the calculations below, stating the amount of energy and CO2 emissions that would be saved if Biocool units were introduced in the Spanish Industrial Park and the European Industrial Park:

THE SPANISH INDUSTRIAL PARK:

70,486,366.67 tons of CO2 equivalent/year would cease to be emitted into the atmosphere

94,316,552 MWh per year would stop being consumed

THE EUROPEAN INDUSTRIAL PARK:

734,232,986.1 tons of CO2 equivalent/year would no longer be emitted into the atmosphere

982,464,083 MWh per year would stop being consumed

Evaporative cooling is better for business

Some of the most renowned industrial production facilities have already installed Biocool evaporative cooling units in their facilities. These groups are not just benefitting from the reduced running costs of these greener solutions, but they have also enhanced their reputations in an increasingly environmentally-conscious landscape.

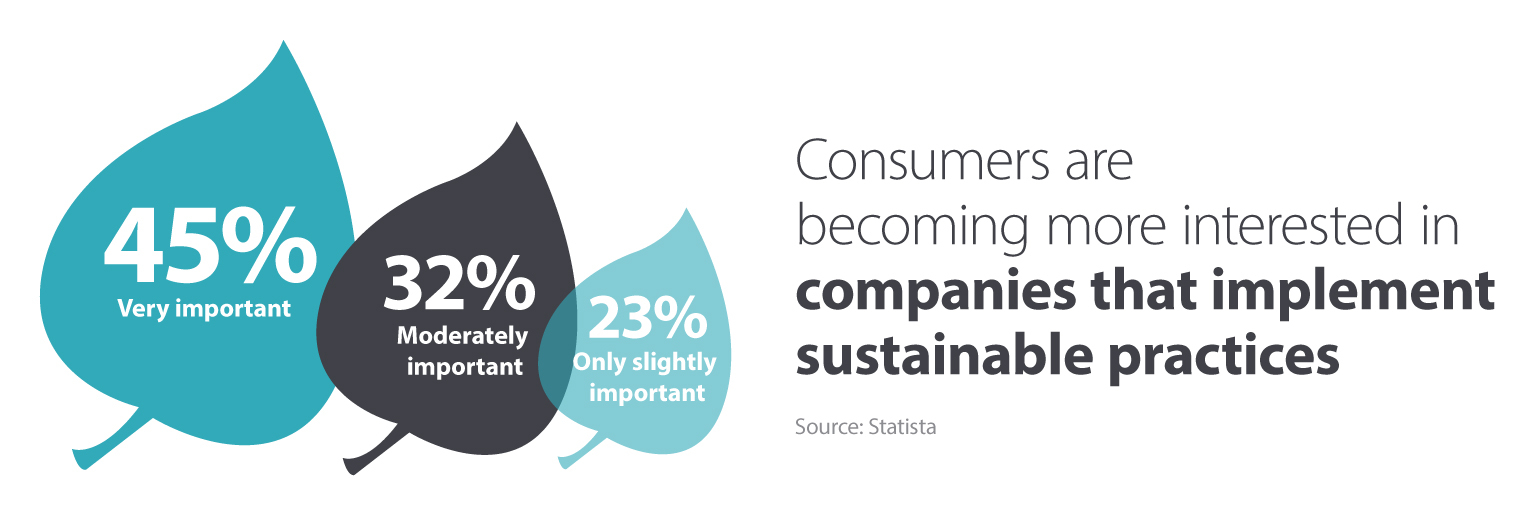

Global warming is a key concern for more and more consumers across the globe, and the ethical practices of businesses are under the spotlight more than ever. In fact, research by Statista found that 45% of consumers surveyed were interested in finding brands that were sustainable or environmentally responsible.

On top of the immediate financial benefits of using evaporative cooling over traditional air-conditioning solutions, the strong environmental message these systems demonstrate to customers can help a business achieve:

- Increased profitability and competitiveness

- A better public image and brand perception associated with positive values

- Better positioning against competitors using outdated, energy-consuming systems

- Increased employee satisfaction and productivity

To learn more about the financial and environmental benefits of evaporative cooling and how to implement this in your building, contact our team of experts via the form below.

Related products

Featured insights

Employing evaporative coolers to protect the health and wellbeing of workers

Why clean air flow is good for business

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.