Lighthouse: Supplying ventilation to Denmark's tallest residential building

- Home

- Insights

- Ventilation insights

- Lighthouse: Supplying ventilation to Denmark's tallest residential building

Discover the ventilation solution we devised for Lighthouse – Denmark’s tallest residential building – and how we worked with the project’s contractors to make their job as straightforward as possible.

For over 60 years, Dantherm has been at the centre of innovative, efficient residential ventilation units across Europe – and particularly in our home country, Denmark. With strict regulations on energy efficiency, emissions and indoor air quality, the ventilation solutions used in residential buildings must be exceptional.

This was especially important in the construction of Lighthouse, Denmark’s tallest residential building, housing close to 400 apartments. Making sure that all homes received ample fresh air all year round, kept energy costs down, and met the contractors’ exact expectations required a sophisticated solution.

Discover how we adapted our mechanical ventilation units to deliver the optimal solution for this standout structure.

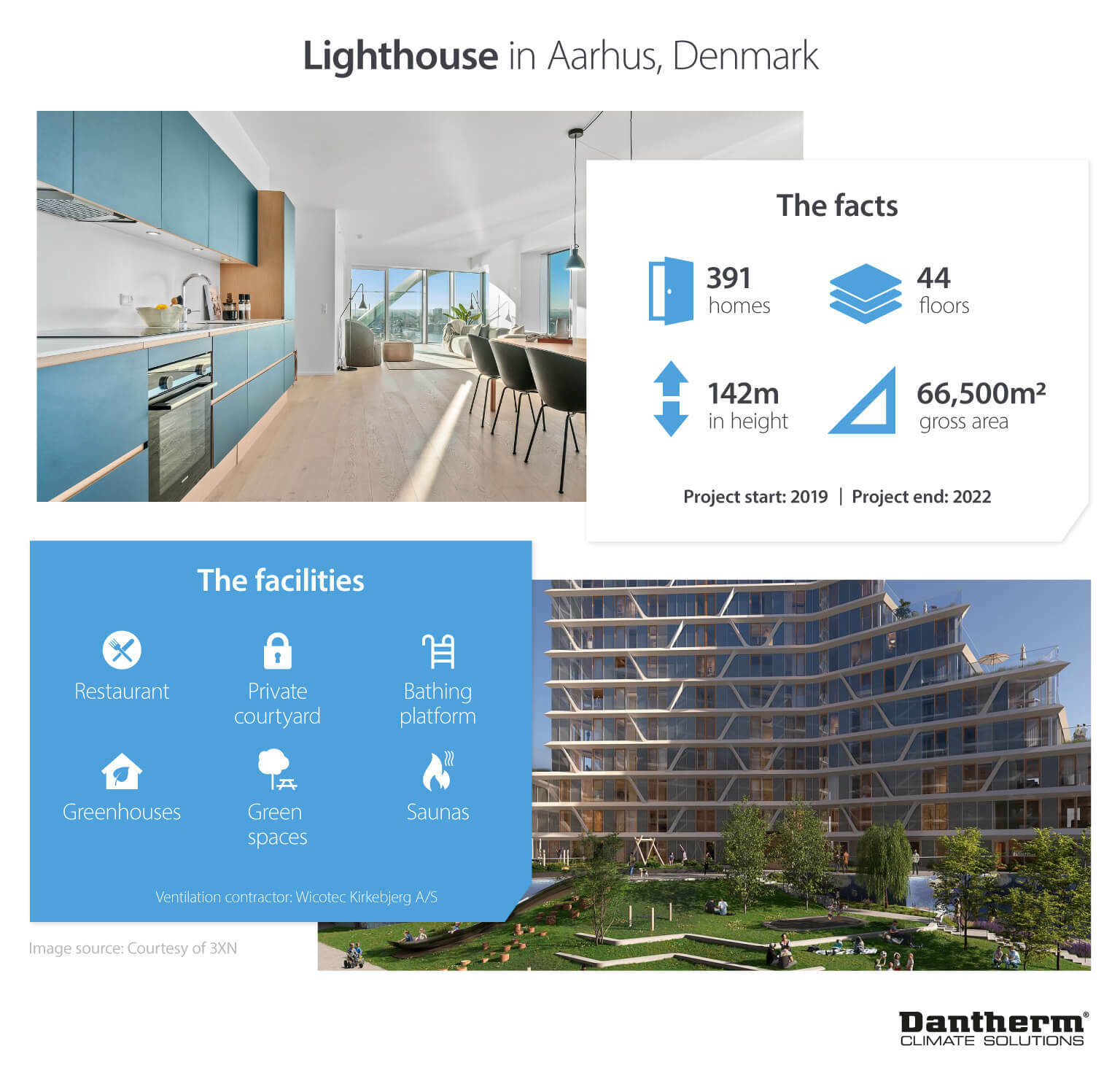

Introducing Lighthouse

Lighthouse, fittingly named due to its beautiful surroundings at the tip of Aarhus, is Denmark’s largest residential building, with its main tower, Fyrtårnet, standing at 142 metres tall.

Built between 2019 and 2022, Lighthouse promises its residents idyllic, bright and stunningly designed homes overlooking the sea. With a restaurant at the summit, a bathing platform at the foot, and a private courtyard on-site, this is a prestige building in every sense of the word.

With “wellness” woven into the fabric of Lighthouse, an effective ventilation system was of paramount importance…

Choosing Dantherm

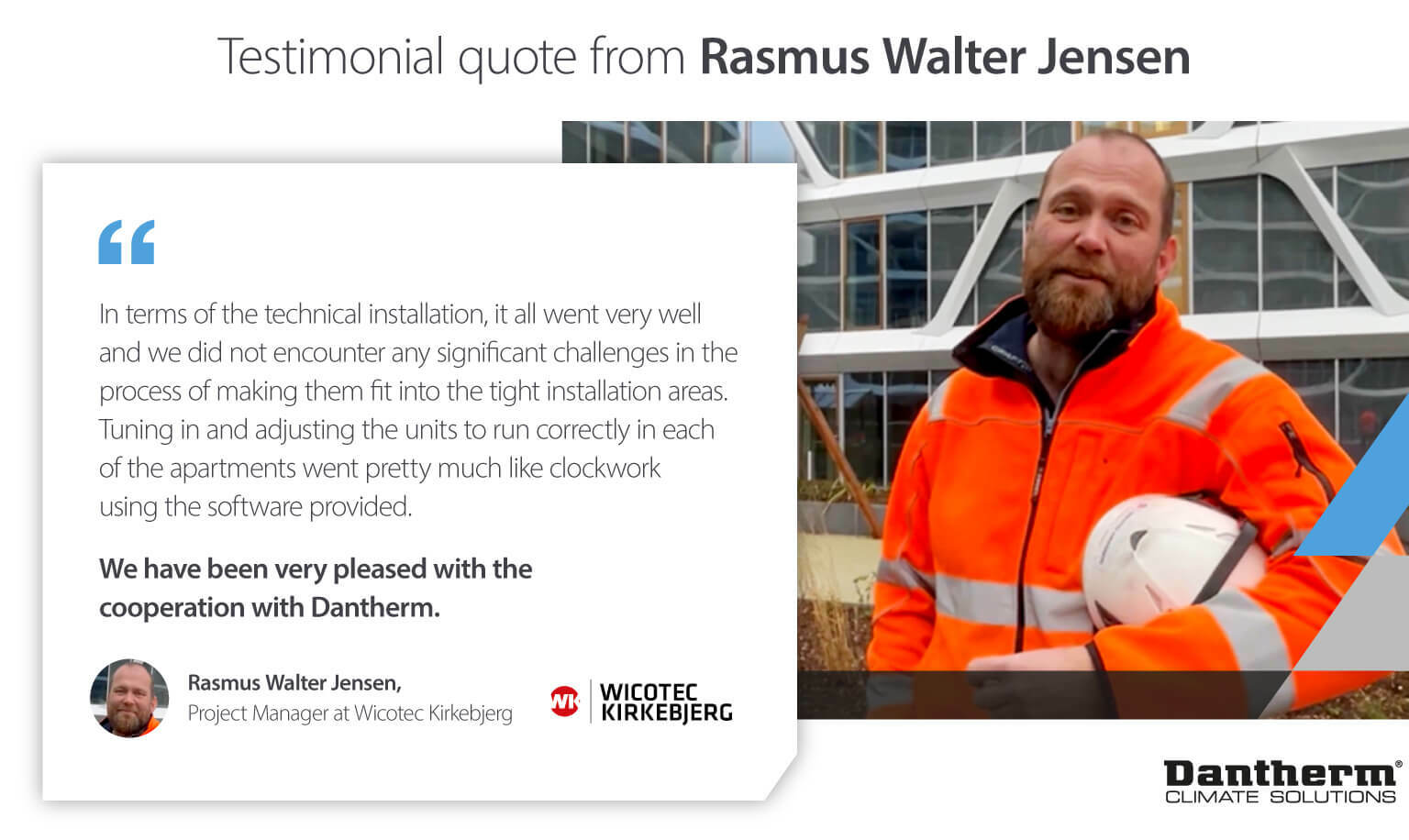

The contractor engineering company in charge of plumbing, electrical installation and ventilation for the Lighthouse project, Wicotec Kirkebjerg – a subsidiary of Per Aarsleff, one of the world’s largest infrastructure groups – initially had another manufacturer in mind when tendering for the project.

However, they soon discovered our solutions at Dantherm offered a superior technological edge over their original choice. Among the reasons they switched include:

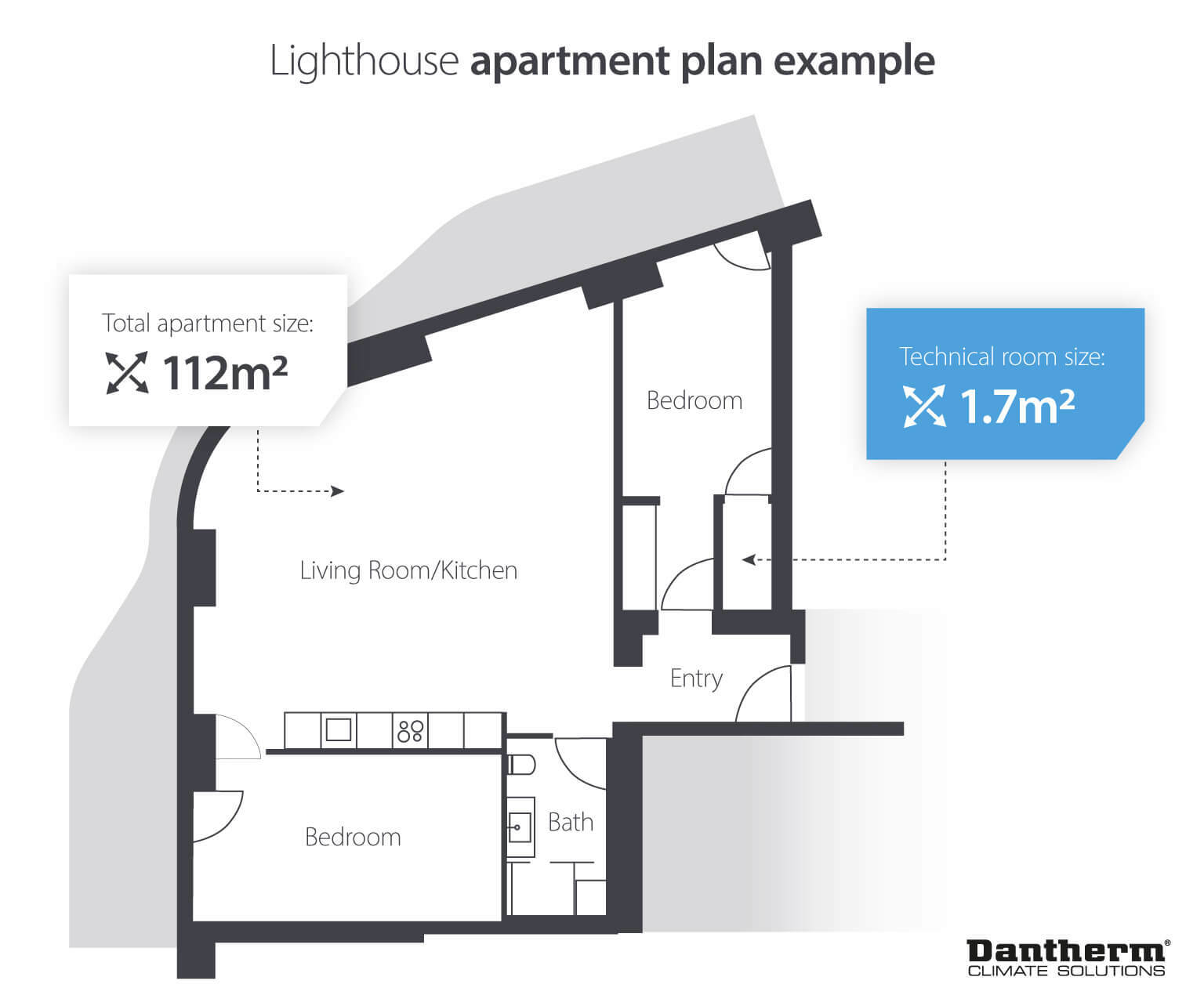

The space-saving potential of our units delivers exceptional air flow to Lighthouse’s apartments while comfortably fitting into compact technical rooms

Our units’ unique ability to connect the supply duct to the base, rather than all ducts being connected via the top, allows for even more space to be saved, cutting down building costs

The superior software behind our residential ventilation units ensures the optimal amount of fresh air is provided at maximum efficiency, from humidity sensors to our Potentialfree Damper Control (PDC)

Our secure Fire Protection Controller secures the building’s decentralised ventilation system against the risk of fire spread

Furthermore, our ability to adapt and evolve our units to meet precise specifications was crucial to this project. Thanks to our leading in-house development facilities and the forward-thinking insight of project managers like Søren M. Kamstrup, we adjusted wherever required to meet expectations.

Our commercial residential ventilation solutions

There are numerous factors that made the HCV 400 PRO P2 the perfect choice for Denmark’s tallest residential building:

Strong air flow

Firstly, despite being compact, fitting in a 60cm x 60cm cupboard, the HCV 400 PRO P2 provides up to 240m3/h air flow – over 60m3/h more than the original ventilation system proposed.

Heat recovery

The powerful heat recovery of our residential ventilation systems makes them among the most energy-efficient available. Our innovative heat exchangers deliver up to 97% heat recovery – far beyond the 80% threshold set by Denmark’s building regulations.

Buildings spend less on energy, structures are preserved for longer, greenhouse emissions are reduced, and the wellbeing of occupants is protected. In buildings the size and breadth of Lighthouse, this can generate substantial long-term savings.

In addition, all units are connected to the kitchen exhaust. Systems increase the ventilation when this is activated, and the excess heat from cooking is reused via the heat exchanger.

Find out more about the benefits of heat recovery ventilation.

Humidity sensors

As part of this project, all ventilation units were delivered with built-in humidity sensors so that they can automatically recognise changes in humidity, and adjusts the fresh air output accordingly.

Free cooling potential

In the summer, indoor temperatures will often exceed outdoor temperatures – especially with the prominence of windows and natural lighting in the Lighthouse apartments.

The HCV 400 P2’s ‘free cooling bypass’ lets in cool night air on hot days to help maintain comfortable temperatures with a special option of increasing the airflow to maximize efficiency. This is a much more energy-efficient and eco-friendly approach than air-conditioning.

Customisable set points

Both the humidity sensors and free cooling bypass are automatically activated through customisable set temperature and humidity points. Once these are met or exceeded, they immediately take effect to keep operations efficient and conditions comfortable.

In addition, following a special request of the Lighthouse project, unique set points can be calibrated for summer and winter months. With distinct apartments having different climate requirements at varying times of year, specific ventilation units can be fine-tuned for maximum performance, comfort and efficiency.

Flexible ducting

One of the standout benefits Dantherm’s residential ventilation units offer over competitors is the ability to fit the supply duct to the base of the unit, with the exhaust duct attached to the top.

This, alongside the compact size of our units, made it much simpler to fit these in each apartment’s technical rooms. As a result, technical rooms could be built smaller, creating more space in the apartments and reducing costs.

Furthermore, with multiple units sharing a common exhaust duct, this reduced ducting compared with a ‘traditional’ ventilation system meant Wicotec Kirkebjerg saved on material costs.

Potentialfree Damper Controller (PDC)

A final standout feature of Dantherm’s residential ventilation units is our Potentialfree Damper Controller (PDC). As increases in air flow can lead to drafts and greater noise, a PDC opens and closes valves to direct air flow, minimising the presence of drafts and noise.

Want to learn more about our residential ventilation units? Explore the sustainable solution we devised for The UN17 Village.

Beyond the HCV 400

The above features, combined with Dantherm’s market-leading expertise, made the HCV 400 PRO P2 the perfect fit for Lighthouse. However, with several apartments in the building only covering a 52m2 area, even this system was too large for some.

HCC 360P2 and RCV 320

In these instances, we found fitting alternatives in the HCC 360P2, able to be installed on ceilings to take up minimal space, and the RCV 320 – our very compact, ingenious solution. Between these three units, we met and exceeded the parameters set by Wicotec Kirkebjerg.

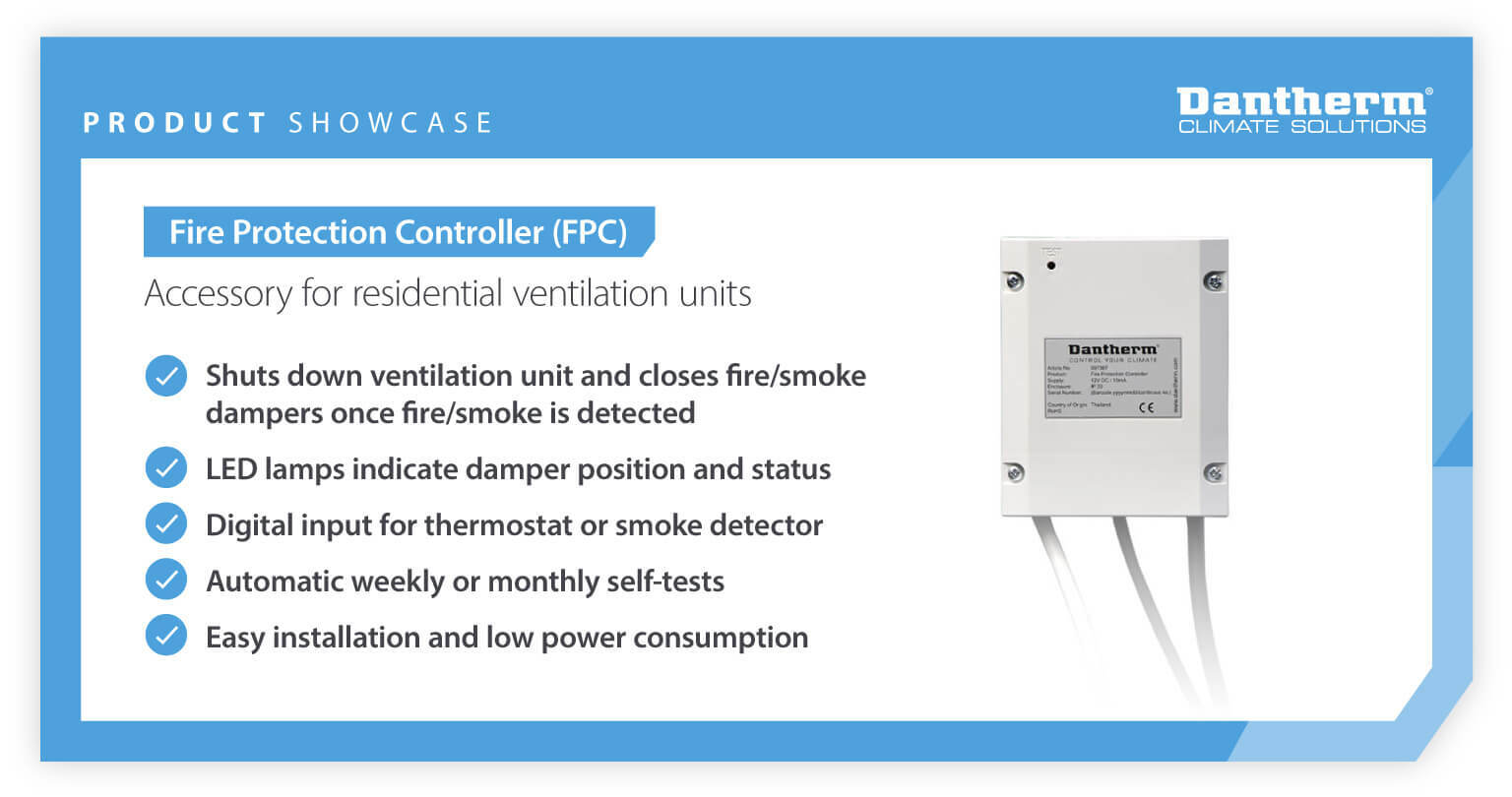

Fire Protection Controller (FPC)

In addition, our Fire Protection Controllers (FPC) eliminated the risk posed by fire. With communal exhaust ducts connecting multiple apartments’ ventilation units, fire and smoke could easily and rapidly spread between apartments without effective safety measures in place.

The FPC removes this threat, automatically closing fire and smoke dampers when fire is detected, removing the possibility of this spreading through the shared exhaust duct.

Going the extra mile

While the technological edge of Dantherm’s units was key to the successful completion of the Lighthouse project, working right alongside this was our team’s end-to-end dedication to supporting our customers in any way we can.

At the outset of this project, we worked closely with Wicotec Kirkebjerg’s advisors to understand their expectations, and outline exactly how we needed to adapt our solutions to meet and exceed these requirements.

From there, we were actively in communication with their team as we configured our units, and were on-site to help make installation as straightforward as possible:

Plus, our PRO units are specially designed to make these easy to handle on-site. This includes straightforward delivery on pallets with minimal packaging, reducing the cost and ecological impact of disposing waste.

Our technical understanding, unrivalled commitment and dedication of professionals like Brian Juul, our technical sales specialist at the heart of coordinating this project, drive us to always go the extra mile for our customers.

If you have enjoyed this case study, and would like to know more about our residential ventilation solutions ahead of an upcoming project, get in touch with us today using the form below.

Related products

Featured insights

Discover why heat recovery is vital to buildings reducing their CO2 output long term.

How we provided a truly sustainable, efficient and effective ventilation system for NREP.

Explore our top tips to minimise energy loss by using residential ventilation with heat recovery.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.