Keep productivity flowing with targeted dehumidification

- Home

- Insights

- Humidity control and drying insights

- Keep productivity flowing with targeted dehumidification

Excess humidity can present a number of problems for water management facilities. As saturated air enters the building, cold pipes, containers, walls and underground spaces are likely to be affected by the build up of condensation. This, in turn, can lead to cracks appearing in the building, damage to equipment, slip hazards for staff and the risk of mould and mildew growth.

Due to the low temperature of water carried through pipework, and the fact that many parts of a water management facility are often underground, indoor temperatures are rarely higher than 18°C. This means that warm humid air that enters the building will condense when it comes into contact with the cold surfaces inside the facility.

While temperature can be difficult and expensive to regulate, the use of targeted dehumidifiers can help remove excess moisture from the air and help prevent condensation in the most vulnerable areas of a water management facility.

4 ways dehumidifiers can help a waterworks run efficiently

#1 Prevent corrosion

Water droplets left on pipework and equipment will soon lead to the deterioration of important components that are vital for the smooth running of a facility. For example, when rust forms on shut-off slide valves and check valves, there are more likely to be delays during general maintenance and, more worryingly, problems during emergency situations.

#2 Protect electrical components

Ensuring that sensitive remote data transfer and electronics components remain free from moisture will not only increase the lifespan of expensive equipment, but also reduce the risk of malfunctions and help avoid false alarms.

#3 Prevent structural damage

In addition to cosmetic damage such as flaking paint and stained walls, moisture can seep into the structural elements of a building, causing efflorescence (the phenomena where soluble salts and other water dispersible materials come to the surface of concrete and mortars) as well as mould growth, which can cause irreparable damage.

#4 Ensure a safe working environment

Mould and mildew can become a danger to people as well as the structure of a building. As it spreads, mould will release toxic spores into the atmosphere, posing a serious health risk to staff working at the facility.

How dehumidifiers work

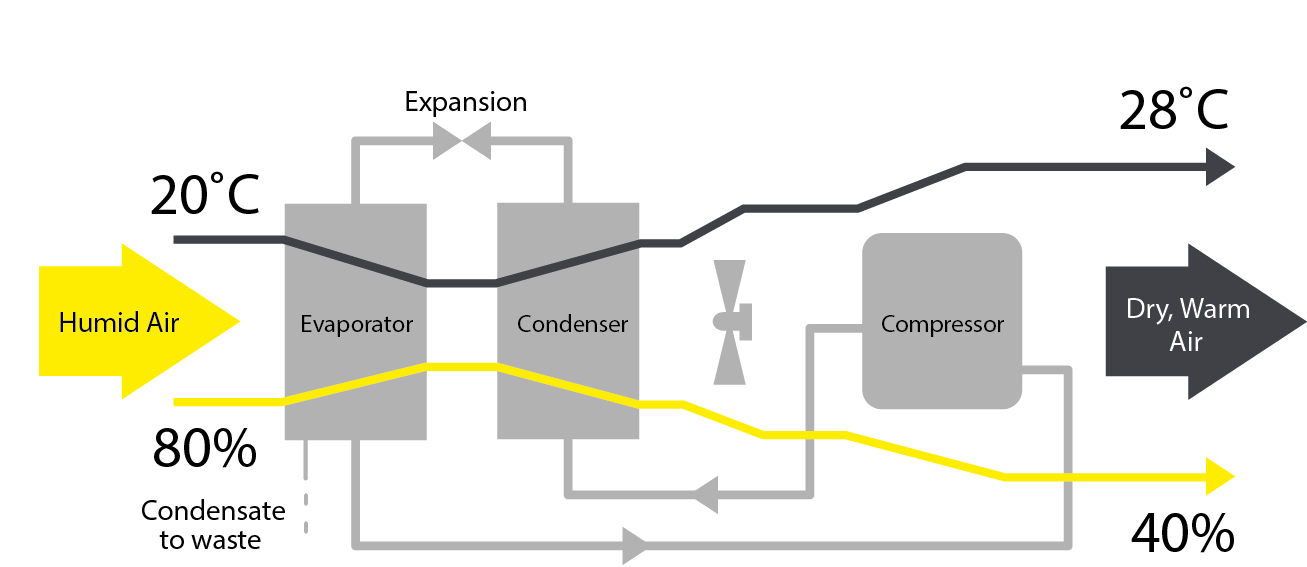

Portable refrigerant dehumidifiers come in various shapes, sizes and capacities. However, they all use the same core principles to control moisture levels in the atmosphere.

A refrigerant dehumidifier consists of a fan, a cooling unit and, if required, an outdoor air intake. The cooling unit includes an evaporator, a condenser, and a compressor.

As humid air flows over a cold coil inside the cooling unit, the water in the air becomes condensation. A refrigerant in the cooling unit then evaporates at low pressure and low temperature, before being condensed at high pressure and high temperature.

Damp air is drawn into the dehumidifier and across a refrigerated coil

The air is cooled below its dew point, condensing the water vapour

Latent heat energy is recovered and re-used

Cooled air passes across the condenser and reheated

The warm dry air is then returned to the room at the required humidity

Water management facilities across Europe have placed their trust in Dantherm Group products to remove harmful moisture from the atmosphere. To find out how your waterworks facility could benefit, and to learn more about the dehumidification systems available, don’t hesitate to get in touch with our team via the form below.

Related products

Featured insights

Maintaining the right humidity levels in waterworks

All you need to know about controlling the humidity levels in waterworks

Expert advice for your next project

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.