Insulation drying – taking a negative approach to deliver positive results

- Home

- Insights

- Humidity control and drying insights

- Insulation drying – taking a negative approach to deliver positive results

Here we explore how negative pressure drying works, the benefits this approach offers in terms of greater control and reduced risk of contaminating the air, and why the Aerial AERCUBE® is the standout drying solution for all forms of water damage restoration claims.

With energy prices rising, the need and demand to insulate buildings is set to soar to drastic levels. This appears to be a sensible attempt in driving down the costs of controlling the climate within properties.

While these modern insulation methods deliver great savings and reductions in carbon emissions, they can go on to encounter issues during extreme weather events such as floods or severe storms.

Due to the nature of these insulated constructions, traditional water drying methods such as condensation drying and air movement are incapable of drying the structure without the assistance of specialised drying solutions such as the Aerial AERCUBE®. When water permeates the cavity walls, mould and bacteria can build up, causing potential health hazards, as well as contributing to structural damage.

Insulation within walls, floors and ceilings can be dried using positive pressure drying methods or negative pressure drying.

What is the difference between positive pressure drying and negative pressure drying?

Positive pressure drying blows dry air into spaces and forces water to come to the surface. This can aerosolise any contaminants hidden within the subfloor or cavities and move them into the air, putting inhabitants at risk.

Negative pressure drying – also known as vacuum pressure or suction drying – sucks the water out of insulation layers. The liquid water is separated and the moisture-laden air flow is passed through multiple filters – removing harmful contaminants such as mould, dust, and bacteria.

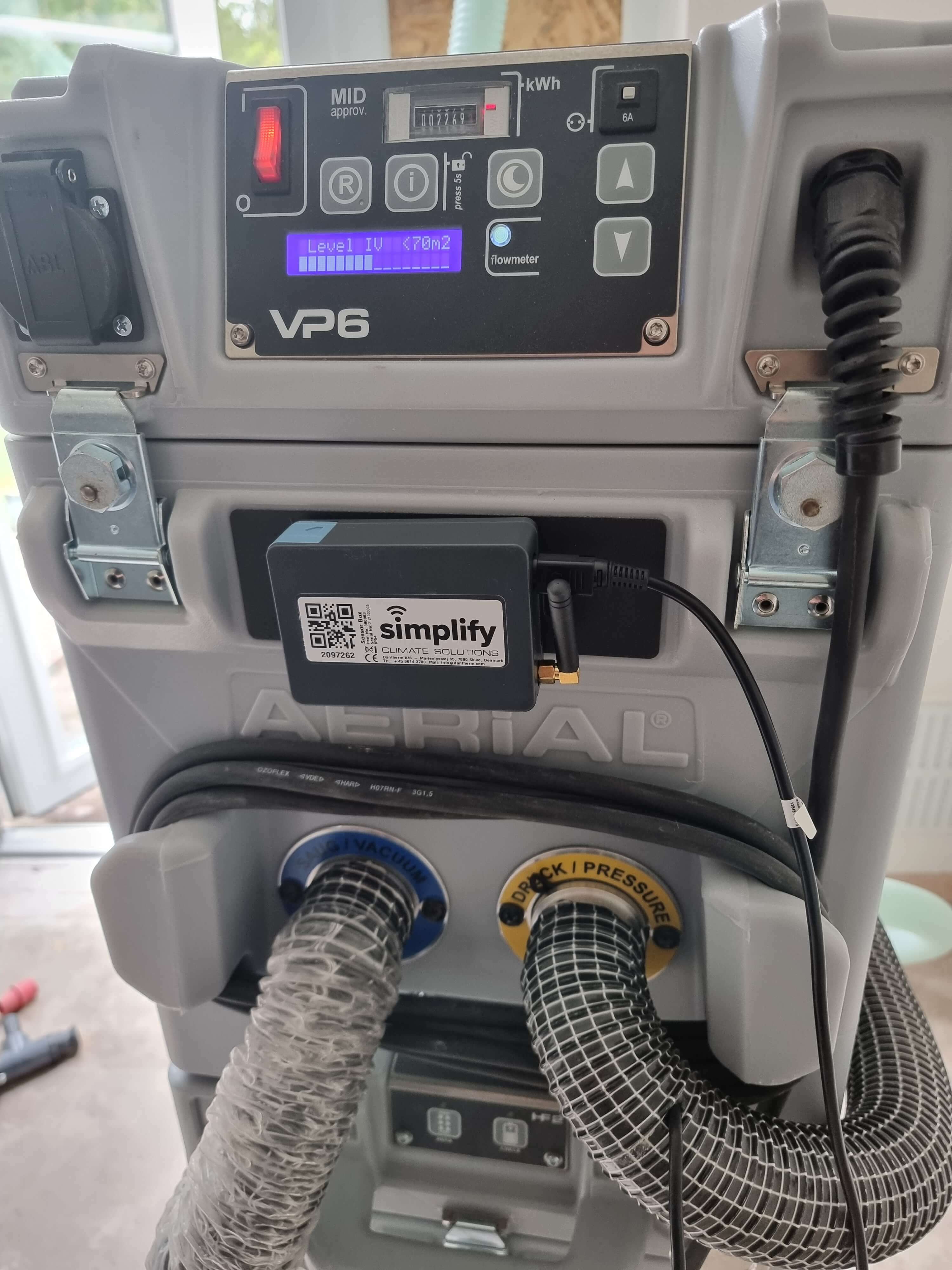

The Aerial AERCUBE utilises negative pressure technology for fast, targeted drying.

Introducing the Aerial AERCUBE water drying system

Most insulated buildings will be built using vapour barriers which prevent or minimise the movement of water (and water vapour) through the layers of the building construction.

Whilst these barriers are great at stopping moisture from getting in, they are somewhat problematic for a drying company when they need to get unwanted water back out of a structure quickly and efficiently.

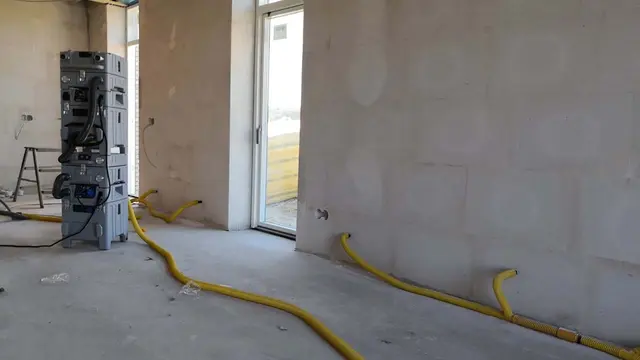

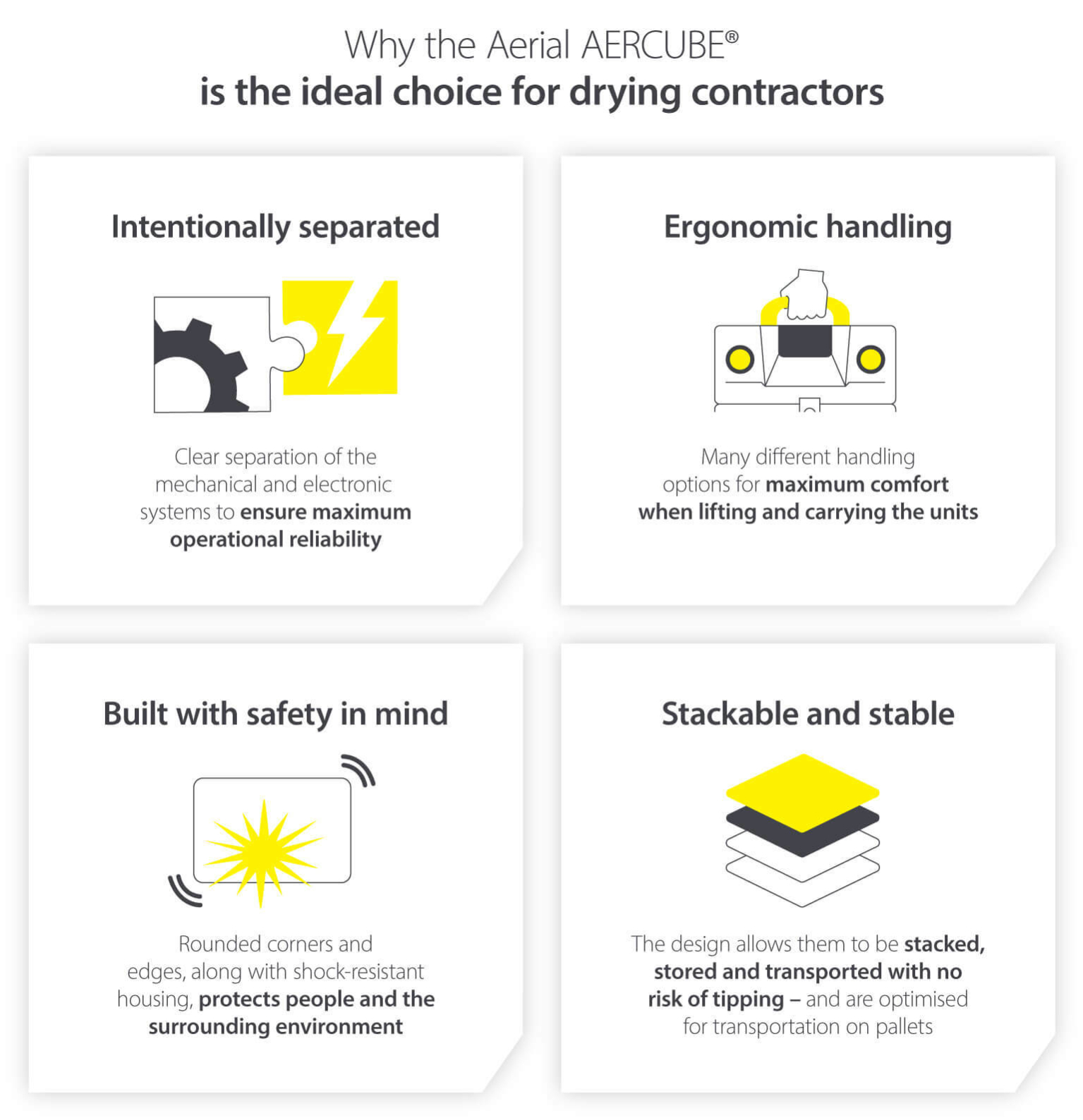

AERCUBE is a vacuum-based drying solution that is specifically designed to target the wet insulation layers held within walls, ceilings, and floors following an escape of water within the construction – minimising the amount of strip-out and reinstatement work required from a construction company.

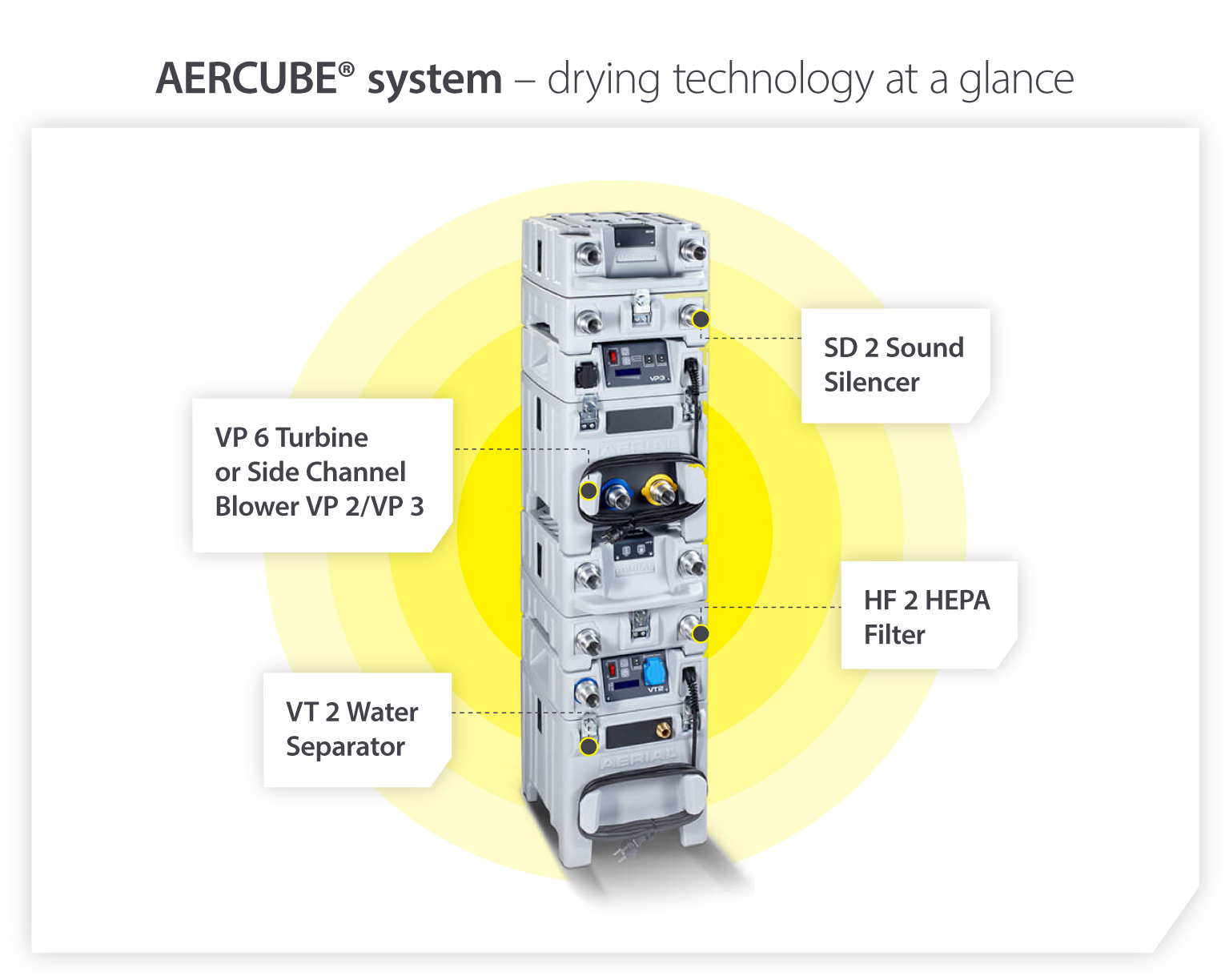

The engine of the AERCUBE is either a side-channel blower or 4-stage turbine which creates a suction force that can be used to extract wet air from within the targeted area.

How does the Aerial AERCUBE work?

What are the benefits of suction drying instead of pressure drying?

The main reason for using a suction-based drying technique is because it offers an unrivalled level of control over the air flow throughout the drying process.

Following a flood or a long-term pipe leak, there is a high possibility of mould and bacteria being present within the interstitial spaces of the construction, such as the insulation layers or within wall cavities.

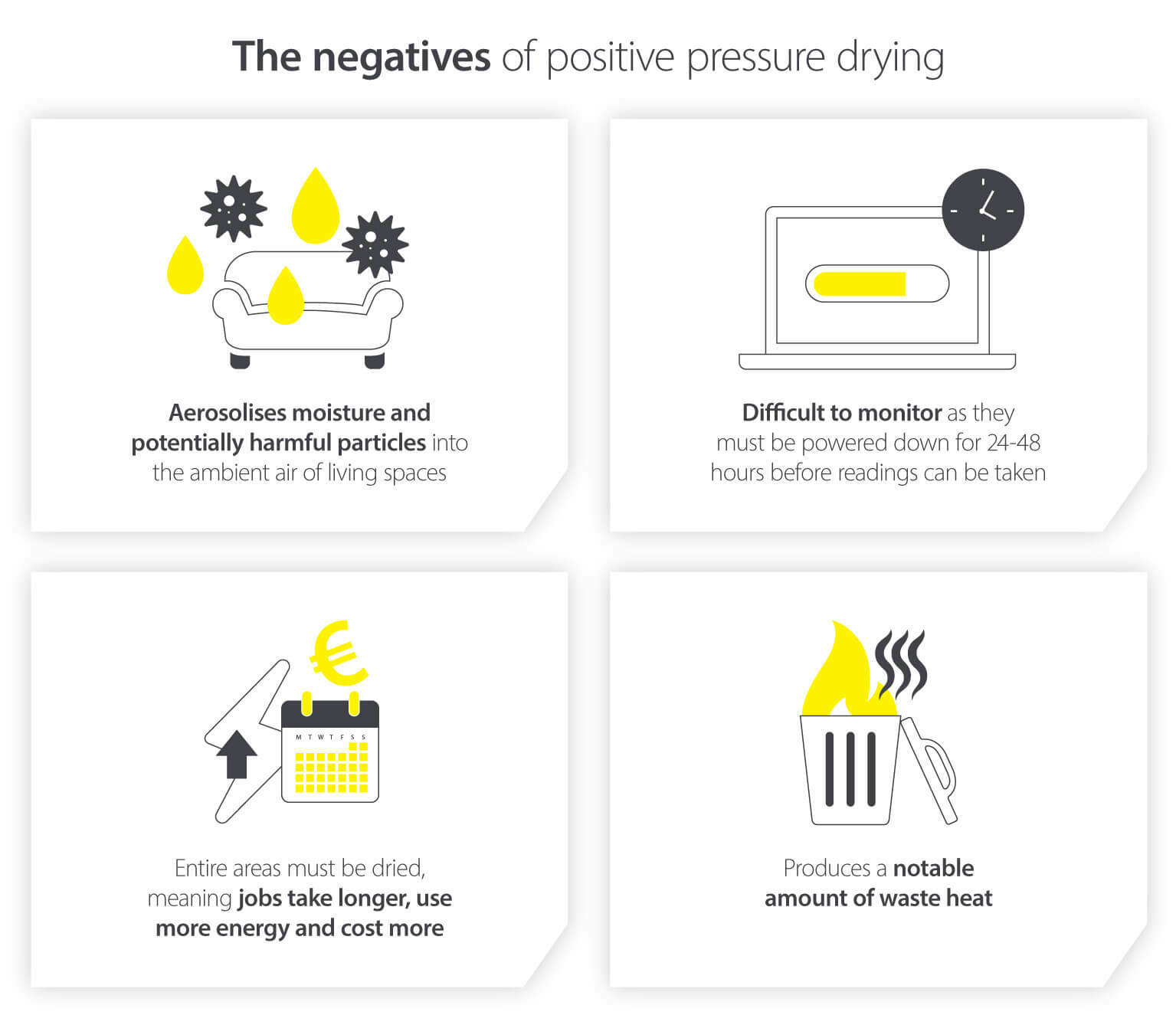

Positive pressure drying is still commonly in use throughout the UK, but there are several reasons why it isn’t widely adopted across the rest of Europe.

How positive pressure and negative pressure differ in application

Positive pressure drying: cross-contamination

Historically, contractors would use a positive pressure drying solution which forced high-pressure air flow into the construction which then vented back out into the room, carrying moisture with it. Unfortunately, this air flow also carried any harmful materials that were hidden in the construction, potentially aerosolising them into the ambient air of the living space.

Other contaminants such as insulation fibres and silica dust also have the potential to be blown into the air and add additional cross-contamination risks.

Negative pressure drying: cross-contamination

AERCUBE uses vacuum pressure and features multiple levels of filtration to remove the risks of cross-contamination.

Starting with the water separator at the base of the tower, the Aerial VT 2 filters out large particles such as insulation and concrete debris from the air flow whilst also removing liquid water which is then purged to a drain in the building.

The moisture-laden air is then passed through a G4 pre-filter and H13 HEPA filter to remove any harmful materials such as dust and mould spores from the air flow, ensuring that they never risk being transferred from the hidden areas of the construction to the living space.

The AERCUBE can also be fitted with an active carbon filter to remove any nasty odours from the contaminated airflow, minimising the risk of those smells torturing the inhabitants of the building.

The filtered air is now safe to be exhausted back into the living space where it can be processed by conventional drying equipment such as a condensation dehumidifier or vented directly outside of the building using a 38mm or 50mm hose.

Positive pressure drying: climate control

Another constraint of positive pressure drying is that this kind of drying system creates a lot of waste heat, mainly from the energy used at the turbine or side channel blower.

In a well-insulated construction, this waste heat can quickly lead to internal temperatures reaching levels above 35°C, resulting in equipment switching off due to operating temperature limits or dehumidifiers losing performance and energy efficiency.

These issues are made worse in the summer months, when drying technicians already face challenges managing internal temperatures during drying.

Temperature control poses other challenges for a water damage technician – with many screed floors being sensitive to sudden changes in temperature, which can cause cracks to appear and result in costly repair works.

Negative pressure drying: climate control

Once again, suction drying offers a solution to this typical constraint faced by a drying contractor, as the waste heat generated by the engine of the system can be vented outside of the building along with the wet air from the construction.

Alternatively, the waste heat can also be utilised during the colder winter months, providing water damage technicians with a way to increase ambient temperatures and maximise the efficiency of their drying equipment.

AERCUBE provides the technician with a flexible and adaptable solution to seasonal drying challenges.

Positive pressure drying: monitoring

Monitoring the progress of your insulation drying is a critical component of a successful project since this style of drying is typically more expensive than conventional building drying, whilst also consuming more kWh of energy per day.

Positive pressure installations can often be quite difficult to monitor as they typically need to be powered down for 24-48 hours before readings can be taken – at which point a decision can be made as to whether to continue drying or sign the project off as being completed. This downtime carries a cost for all stakeholders of the project.

Negative pressure drying: monitoring

Suction drying allows contractors to continuously monitor the drying process using systems such as remote monitoring, with the contractor simply placing temperature and humidity probes in the hoses that carry air from the insulated construction.

The reason this works well is because the contractor isn’t abnormally heating the building materials when using a suction-based solution and this allows normal measurements to be taken continuously with no interruption to the drying process and no downtime.

These measurements can also inform the decision-making process for a technician as to whether they should power down equipment remotely, saving significant amounts of electrical power per day and reducing the overall carbon footprint for the claim.

Positive pressure drying: a targeted approach

A pitfall of positive pressure is that the entire area needs to be targeted to enable sufficient pressure to be built up in the construction – increasing drying times, using more energy, and costing significantly more.

Negative pressure drying: a targeted approach

Suction drying provides a targeted approach to drying an insulated construction, as the technician can place the suction hoses in the identified wet areas and focus all of their efforts (and energy) on the affected sections of a building.

In many cases, the water damage can be confined to a small section of a much larger area.

Negative vacuum drying in action: a residential care home case study

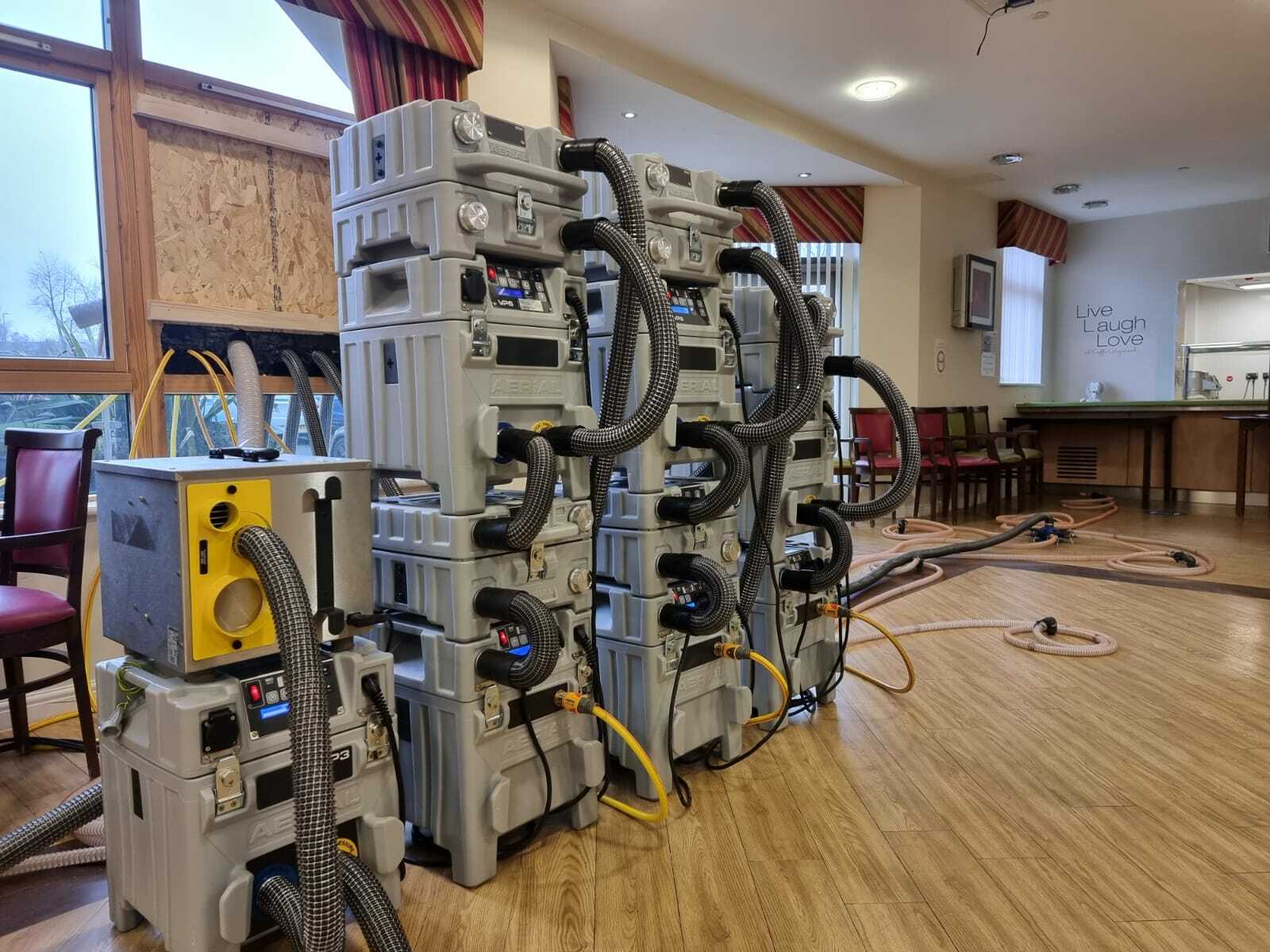

A care home in South Wales suffered an escape of water in 2021 which affected the insulated concrete slab across the entire ground floor of the property.

The property was an active nursing home and the tenants could not be moved out due to medical reasons, COVID-related issues and rehoming costs. A plan was put in place to dry the property using Aerial AERCUBE alongside traditional drying equipment.

A suction-based (negative pressure) drying approach was chosen as it allowed the contractor to target-dry specific areas of the building in different stages. This afforded the nursing home the flexibility to close down sections of the building and relocate activities from one area to another without disrupting residents.

If positive pressure drying technology was used in this scenario, the water damage restoration process would have heightened noise levels, increased indoor temperatures and contaminated the living space with potentially hazardous particles from wall cavities.

As well as compromising the comfort of those living and working inside the property, positive drying could also present a greater risk to the health and wellbeing of occupants, especially those more vulnerable.

Final thoughts on suction and negative pressure drying

After two years of living with the impact of COVID-19, we are all far more aware of air quality and what we are breathing in than ever before — whether it be dust, mould, bacteria or harmful materials such as silica and asbestos.

With this in mind, the ability to employ a suction-based drying technology such as the Aerial AERCUBE will become an even more critical part of a drying contractor’s toolkit, alongside Aerial dehumidifiers to accelerate the process.

If you would like to learn more about structural drying, water drying solutions or the key features of the Aerial AERCUBE®, get in touch by completing the form below.

Related products

Featured insights

Learn why pressure drying is a critical tool moving forward to dry out today’s insulated buildings.

Discover how to determine the most effective Aerial drying solution based on your needs.

Top tips for drying out buildings

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.