How to prepare evaporative coolers for the winter season

- Home

- Insights

- Cooling insights

- How to prepare evaporative coolers for the winter season

Maintaining evaporative cooling units is simple, but many people fail to prepare them for the winter months, which can significantly reduce their effectiveness, and in extreme cases render them unusable.

Most air-conditioning and cooling takes place in the summer months, except for the industries that generate high temperatures indoors from their production processes. The latter scenario can see evaporative cooling harnessed way into the autumn-winter months and often right through.

But for everyone else that largely relies on cooling only in the summer months, correct maintenance during the device’s downtime is still critical.

Why is correct maintenance important?

Aside from its core function of cooling, Biocool’s evaporative coolers ventilate and renew the interior areas with 100% exterior air, a necessity in many businesses for both summer and winter months. This function ensures quality and aerosol-free air that also maintains the correct levels of CO2 in the interior areas.

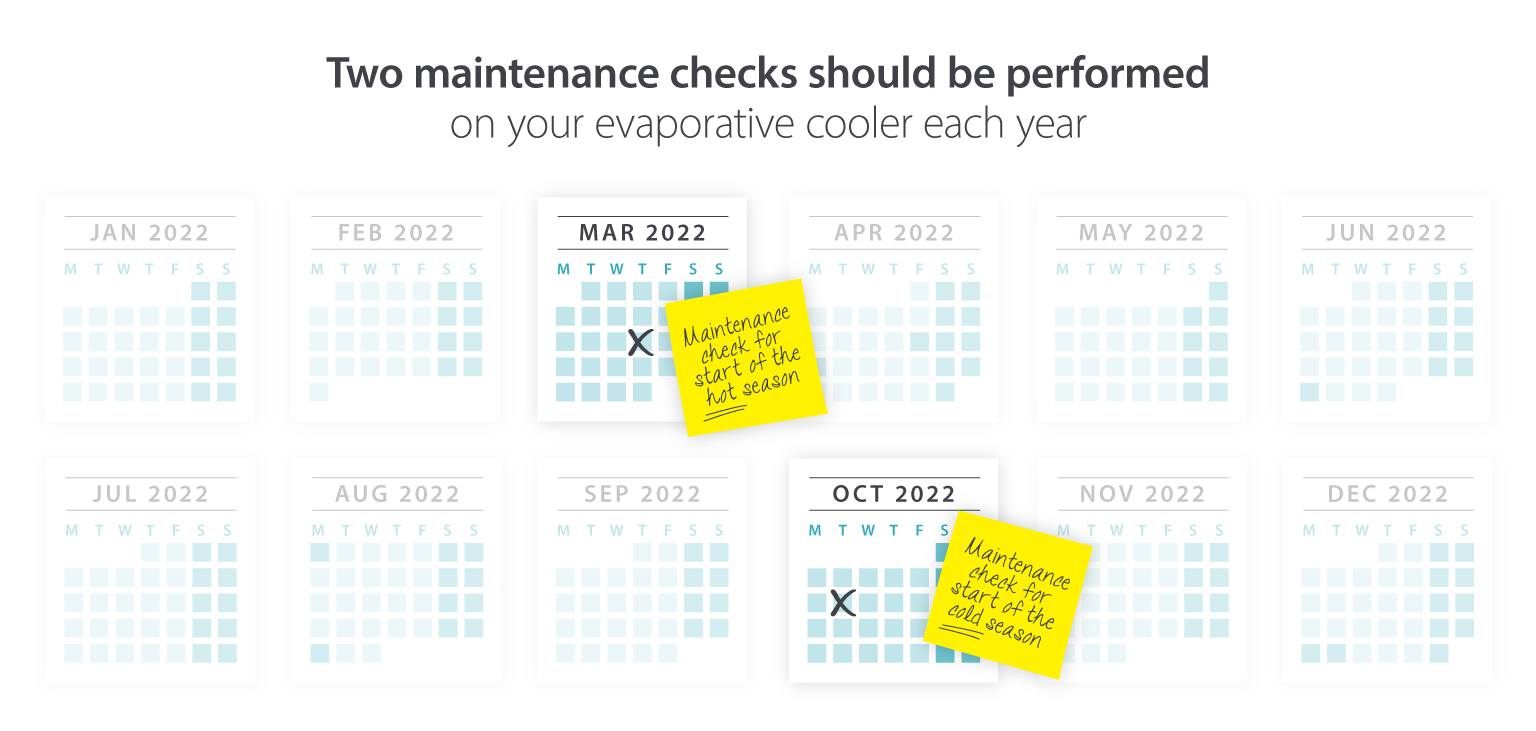

Because the units play such a key role in keeping environments cool, comfortable and healthy, it’s important that they function as well as possible, for as long as possible. We recommend two annual maintenance checks for units, one at the beginning of the summer and one going into the winter months.

In highly polluted environments or where the operation of the equipment is prolonged, we strongly advise that maintenance be performed more frequently (at least every 3 months).

Failure to maintain units correctly can lead to serious consequences including:

Leaks inside the facilities

Loss of up to 48% of cooling efficiency

Component breakages and costly repairs due to lack of proper maintenance

During the colder winter months (when your evaporative cooler is likely not in use), it is possible for the water that remains inside the unit to freeze around particular components.

If not checked at the beginning of the hot season, this frost may have caused noticeable damage to the inner workings of your evaporative cooler. If this damage is not addressed, the units may malfunction when used more regularly, reducing performance and eventually leading to costly repairs.

Similar to the problem above, over time, harsh outdoor conditions (rain, snow, pollution, etc.) can cause mineral deposits to build up inside the evaporative cooler.

Like freeze damage, these deposits can gradually damage and corrode components within the unit, reducing its performance, operating life cycle, and requiring expensive repairs (or perhaps requiring the entire unit to be completely replaced).

All this is solved with correct maintenance of the equipment closing once the season of use ends.

Your guide to evaporative cooler maintenance for the winter season

Maintenance helps to ensure the system is running as it should be and prevents costly, time-consuming issues from arising.

By following the guidance in this article, you will be able to:

Prevent water from entering the installations

Detect clogged filters inside the evaporative system

Prevent damage to mechanical components due to poor quality supply water

Obtain maximum effectiveness and performance of the air-conditioner

The maintenance of Biocool evaporative air-conditioners is very economical compared to traditional air-conditioning systems that require a compression cycle.

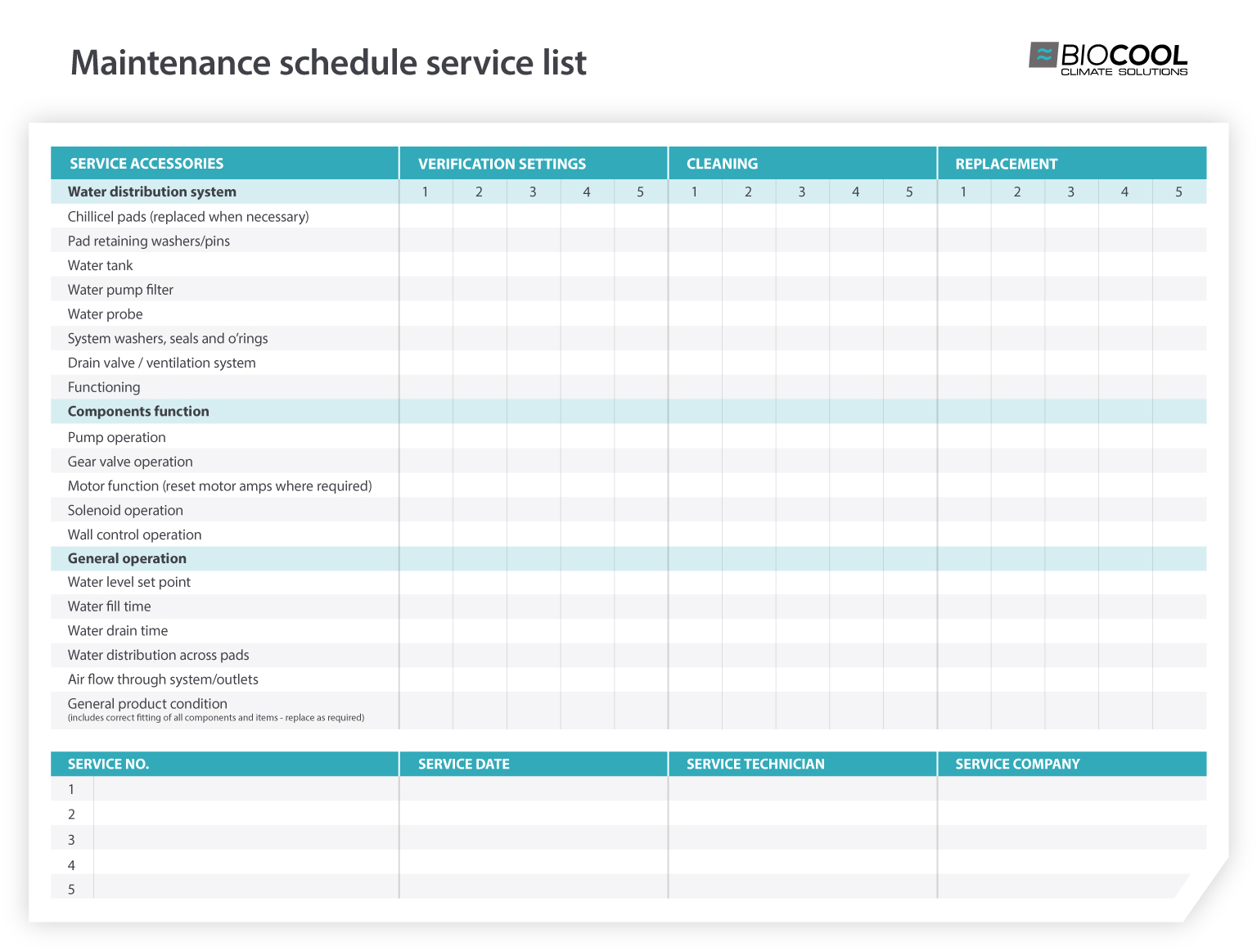

A maintenance schedule is essential to guarantee a correct review of the equipment and that work is carried out, meaning the cooler will operate effectively for many years.

Here is an example maintenance schedule to use as a basis:

Does maintenance differ between portable and fixed coolers?

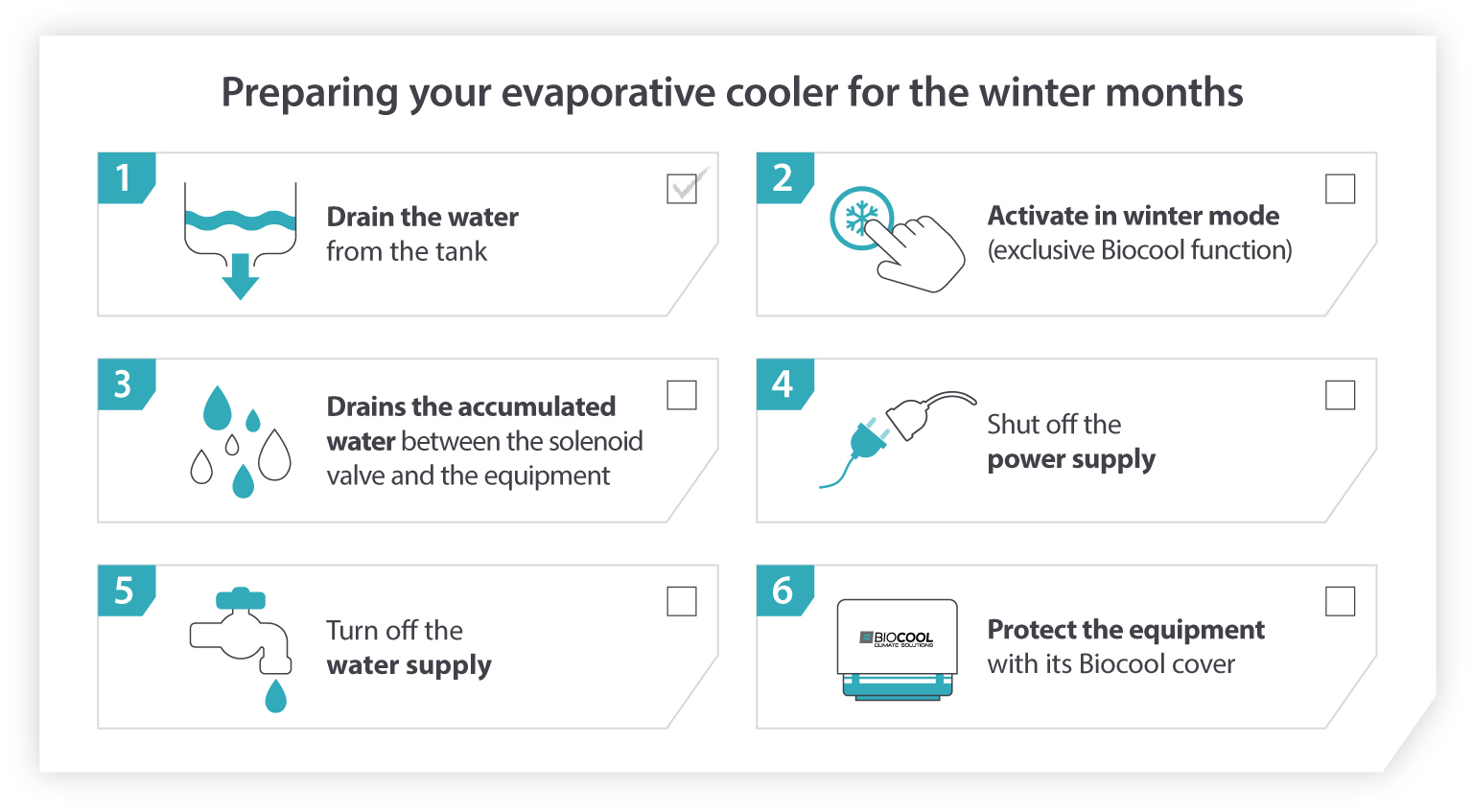

Maintenance is very similar in both cases. It consists of leaving them empty of water, clean, disconnected from power supplies and covered to better preserve them during their disuse.

Biocool fixed evaporative coolers have a winter mode, which facilitates their maintenance during closure as well as correct conservation during the time they are unused. In addition, it avoids the ‘chimney effect’ during winter, which consists of cold air entering the interior area, causing discomfort and low temperatures.

In addition, the placement of covers for both fixed and portable equipment ensures their correct conservation during the period of non-use and simplifies maintenance once its use is resumed, because the units will not be exposed to as much dirt.

The importance of winter preparation can’t be underestimated

If you want to ensure your unit remains at optimal efficiency and stays working harder for longer, follow the steps we’ve outlined in this article. We take great pride in having created coolers that stand harsh conditions and the test of time for over 20 years.

Don’t wait any longer, start getting your evaporative cooler winter-ready today. Still have questions? Get in touch using the form below.

Related products

Featured insights

Be perfectly prepared for the summer with our top maintenance tips

The multi-purpose power of Biocool’s evaporating cooling systems.

Why clean air flow is good for business

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.