How to create healthy air conditions in industrial spaces

- Home

- Insights

- Cooling insights

- How to create healthy air conditions in industrial spaces

The industrial sector is a broad and fast-moving business. Every application and type of building varies greatly, and so do the characteristics. This means that climate control can be a challenge. Here we explore how to overcome it…

When producing any type of product in a factory or industrial setting, there are 2 key priorities:

The wellbeing, safety and productivity of employees

Ensuring the quality of production processes and final output

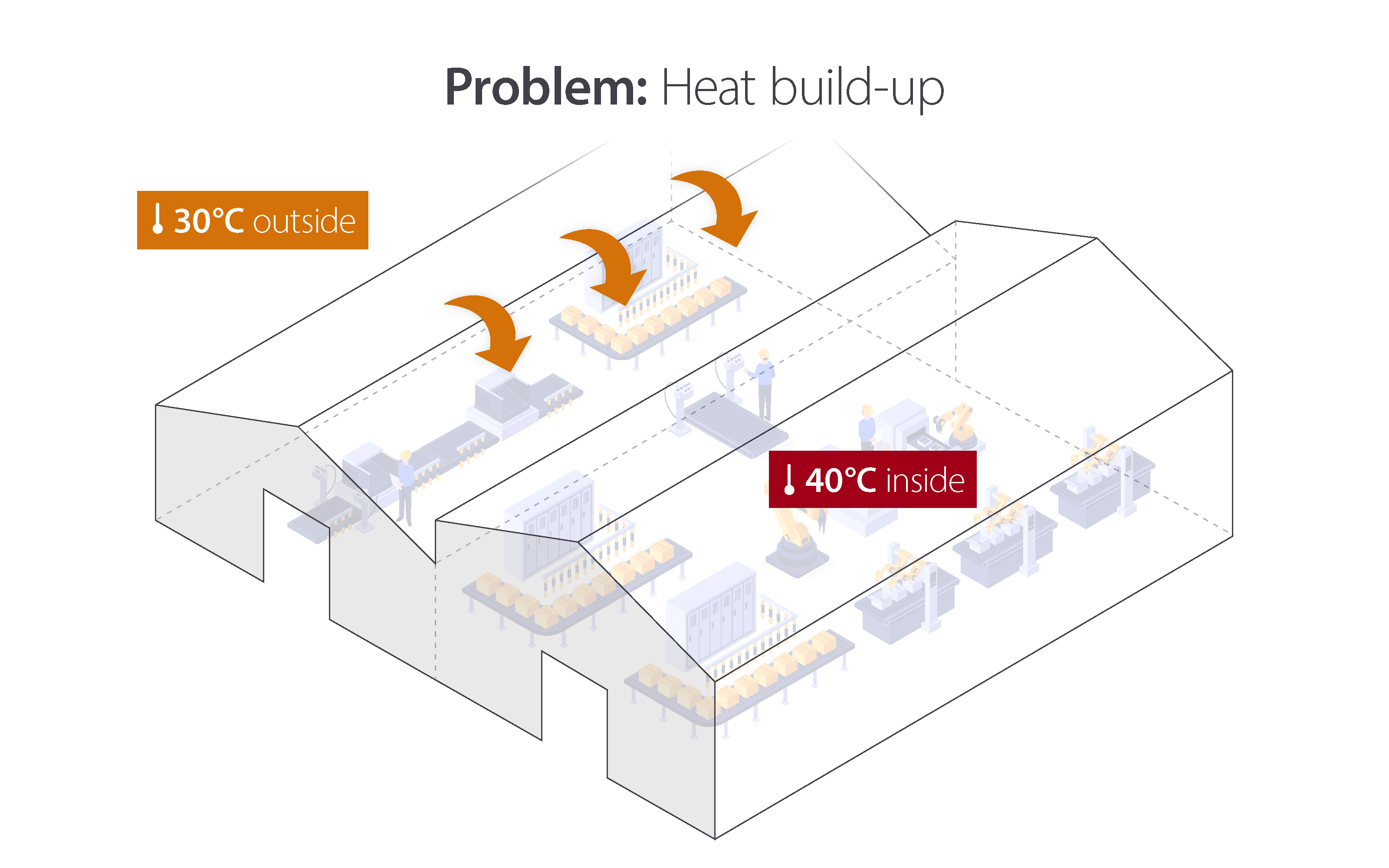

Heat build-up is a common difficulty in the sector, while bad odours, fumes and polluting gases can also contribute to creating a harsh, uncomfortable and sometimes damaging environment.

Reducing heat build-up in large spaces and maintaining a high level of air quality is essential to ensure that workforces are healthy and safe, processes can proceed without disruption, and your final product is the best it can be.

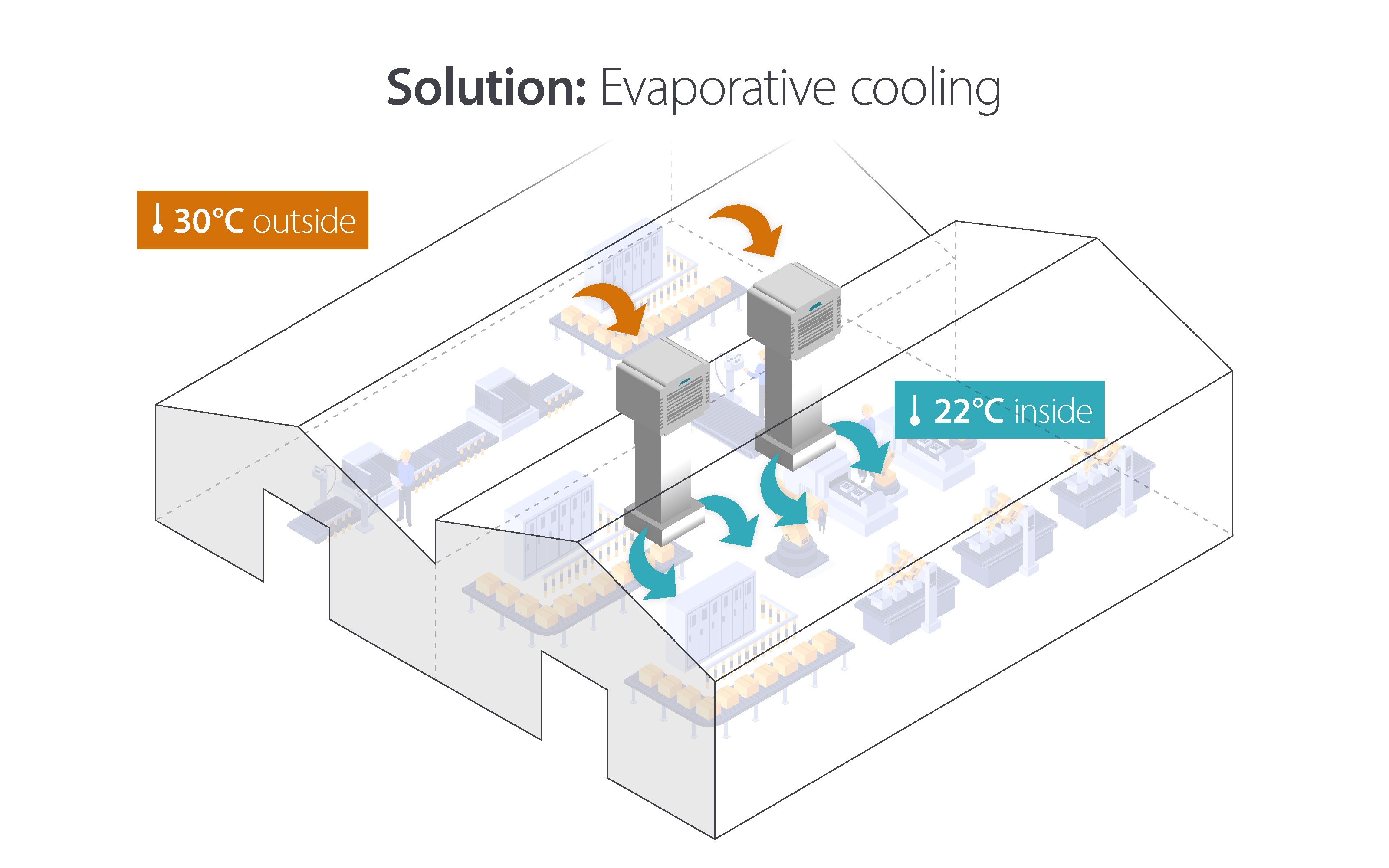

Evaporative air cooling is especially effective in the cooling of large spaces, such as industrial buildings. Traditional air-conditioning is much less effective and much more costly.

The energy consumption of a Biocool evaporative cooling unit is minimal, around 80% less than air-conditioning – an incredible saving in both the short and long term.

Overcoming the challenges with evaporative cooling

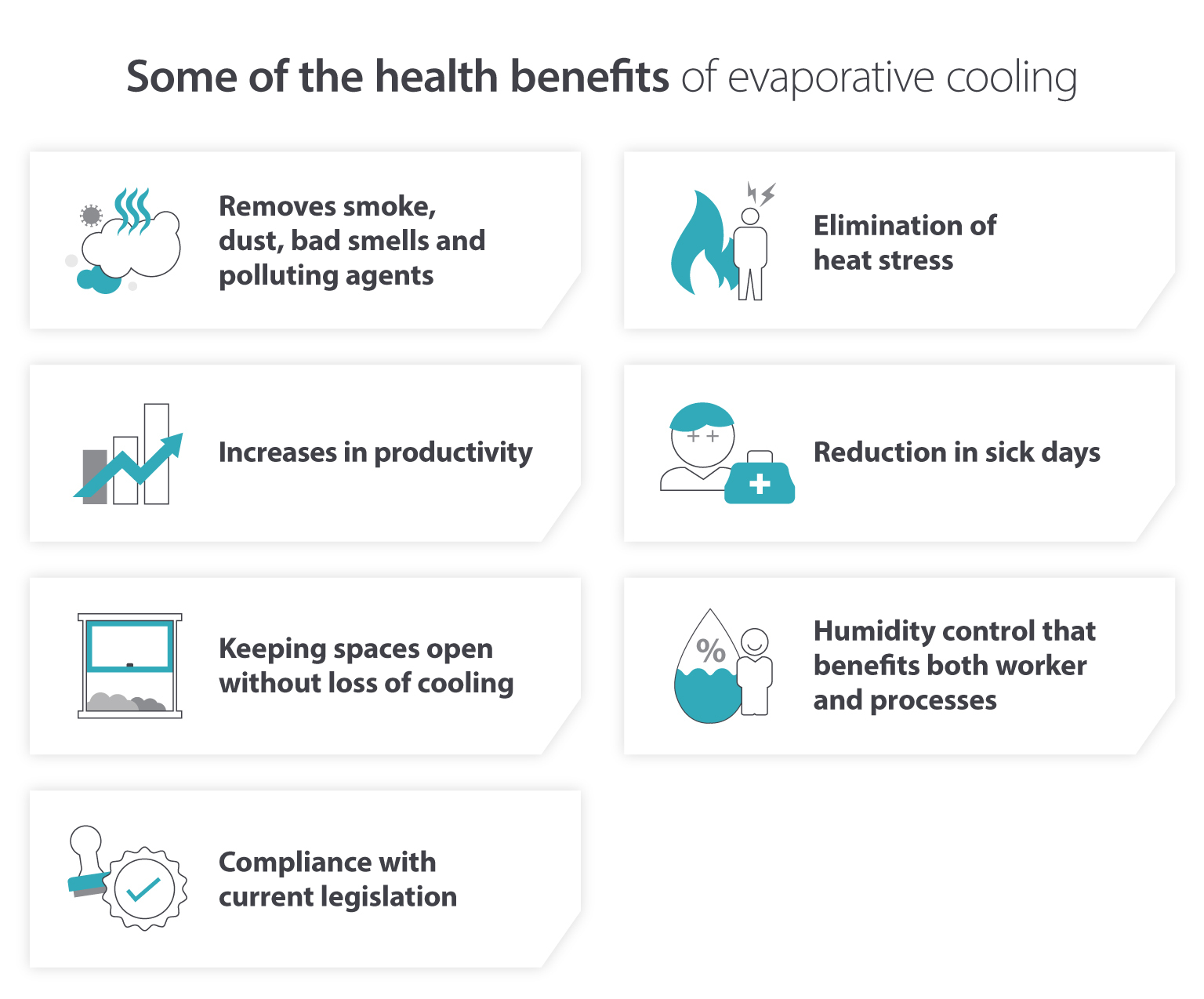

Eliminating heat stress. Removing smoke, dust, bad smells and polluting agents. The benefits of evaporative cooling are vast and contribute to the positive maintenance of your indoor environment in a significant way.

For example, retaining the correct humidity, temperature and ventilation levels have been known to increase labour productivity. Plus, because the air doesn’t carry the same risks as it does with traditional air-conditioning, the unit can directly help to reduce absenteeism and health issues – all while keeping your business compliant with health guidance.

Of course, this precise environmental climate control is also exceptionally beneficial for many industrial processes, too.

Industrial applications that benefit from improved air quality

Pharmaceutical warehouses

The nature of the pharmaceutical industry requires that buildings have exceptional working environments, including product storage, exacting conditions, measures to avoid contamination amongst other regulations.

The quality of the drugs being produced is an absolute priority, and every care must be taken to preserve purity, richness, efficacy and safety.

Storage conditions are critical to maintaining product stability. Evaporative cooling can ensure a suitable and non-extreme temperature is in place to avoid sudden changes, as well as helping to prevent contamination by removing pollutants, dust and bad odours from indoors to the outside.

Wood industries

As a natural material, wood is highly sensitive to dry environments. If exposed to unsuitable temperatures and humidities, it will dry out, crack and become unusable.

Biocool helps to regulate optimal humidity and temperature, whilst ensuring that no unwanted particles are present in the air.

Paint sector

As a flammable substance, paint carries extra risk and needs special care and handling when it comes to storage. Evaporative cooling keeps the storage environment at the right temperature, cools softly not extremely, eliminates static electricity and reduces dust and other particles in the air – all helping to retain the quality of product.

Plastics sector

It’s common for dust to accumulate on plastic surfaces. When it comes to production, an evaporative cooling unit is essential for removing this from the air.

Likewise, odours, bacteria and even insects that could end up embedded in the material are eliminated.

Sectors with volatile products

Volatile products can be categorised where organic solvents are used, such as paints and varnishes, in the steel, wood, cosmetic and pharmaceutical industries. Correct storage is essential to prevent these materials from deteriorating. Otherwise, they can harm the environment and human health.

Thanks to bioclimatisation during the evaporative cooling process, fire risk is reduced, while gases and odours are abolished.

Automotive industry

Car dealerships are vast, well-lit spaces that require large quantities of energy consumption.

Each area – workshop, showroom and offices – requires a different level of temperature and humidity control for the different applications. Standard ventilation is ineffective and not cost-effective in large spaces, whereas evaporative cooling delivers adaptive technology.

- The showroom usually has large window glazed spaces and therefore needs cooling in the summer. Moisture levels need to be low to not corrode the metals. The extensive lighting fixtures also contribute to raised temperatures.

- Workshops need high levels of ventilation that removes harmful gases generated by gasoline and solvents.

- Offices need to keep employees and customers comfortable and safe.

All of these requirements sound demanding, but the capabilities of evaporative cooling mean the technology can adapt to different environments and needs, while retaining optimal levels of humidity, temperature and ventilation.

Benefits of evaporative air-conditioning versus industrial ventilation

Using traditional industrial ventilation for such large spaces isn’t always suitable as it can’t reduce the temperature of the industrial building – it is simply ventilated and will only maintain the outside temperature.

Biocool solutions are much more sustainable. Our evaporative cooling systems take the air from outside, pass it through panels moistened with water, reducing its temperature between 7ºC and 20ºC and propelling it into the interior of the warehouse.

This ensures that the air inside the industrial building is 100% filtered air and the humidity level is kept at consistently comfortable levels.

When it comes to choosing a solution in industrial applications, Dantherm Group's knowledge is second-to-none. If you want to improve the climate and working environment in your industrial setting, we can help. Get in touch using the form below or view our product range here for more information.

Related products

Featured insights

Achieving sustainability through innovation.

Employing evaporative coolers to protect the health and wellbeing of workers

Why clean air flow is good for business

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.