How long does it take to dry out water damage?

- Home

- Insights

- Humidity control and drying insights

- How long does it take to dry out water damage?

Depending on the severity of water ingress, it can take anywhere from a few days to a few weeks to dry a wet property out. In this article, we discuss what contractors should bear in mind when estimating project times and what can be done to speed up the drying process.

When disaster strikes and a building has to contend with excessive amounts of water, be it the result of sudden flooding or an unnoticed leak, this moisture can quickly seep into a structure’s many layers.

As well as soaking materials such as wood flooring or interstitial insulation, the presence of water can create unpleasant living conditions, erode structures, and deteriorate the integrity and safety of a property from the inside out.

To stop moisture from causing irreparable damage, it is important to act quickly. The longer water is allowed to fester, the more severe the damage and the more unsafe the living conditions.

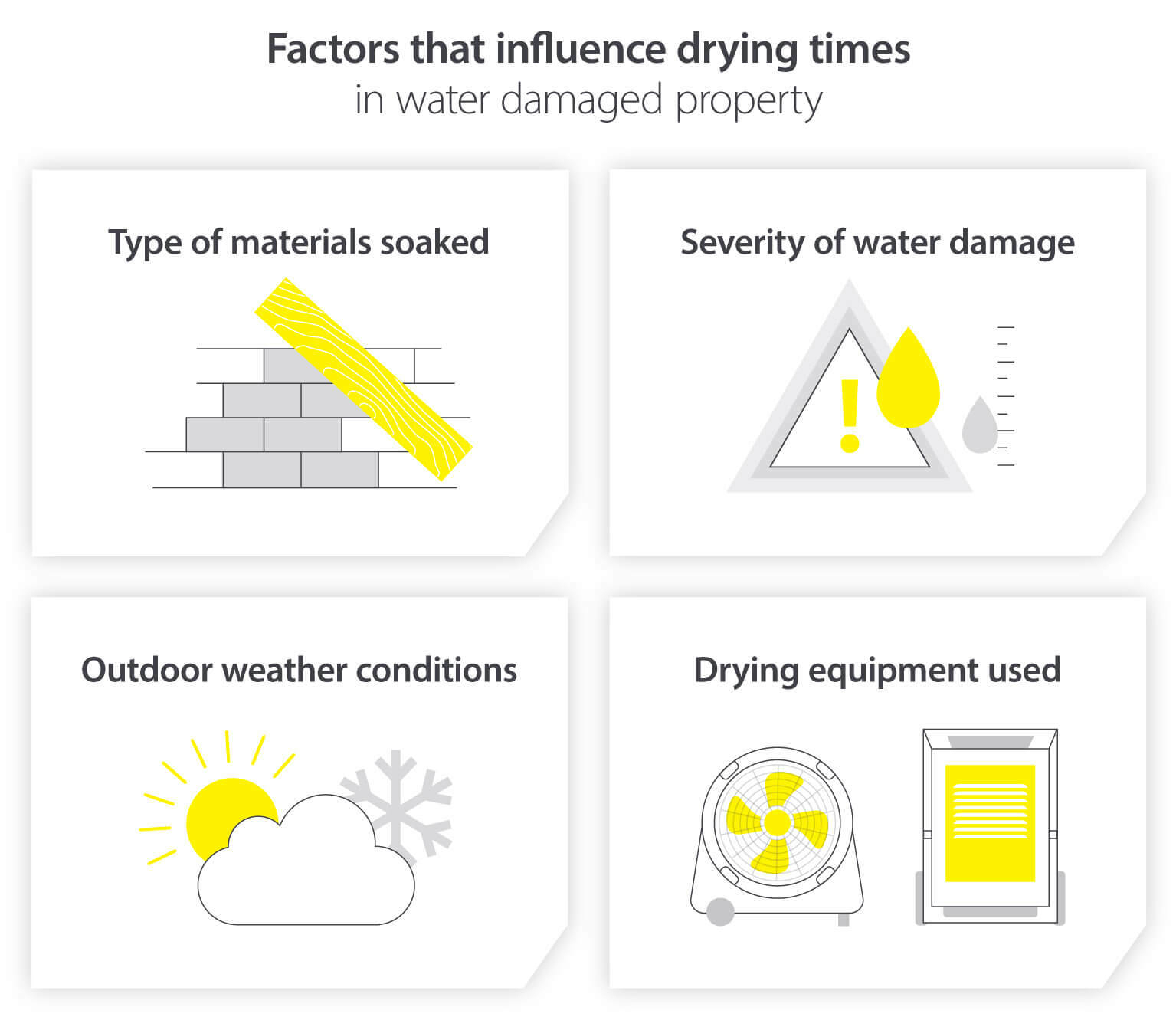

However, the water damage drying process is unique to each and every project, and can take anywhere from several weeks to several days to dry. This is because the rate at which a project can progress depends on a variety of factors, such as:

Although the time it will take to complete a water damage restoration job is difficult to gauge before work commences, there are devices and techniques that teams can use to measure the progress of their work, and speed up the rate at which affected areas dry.

Read on to learn how to assess water damage and the quickest methods for drying wet property.

How does water damage occur?

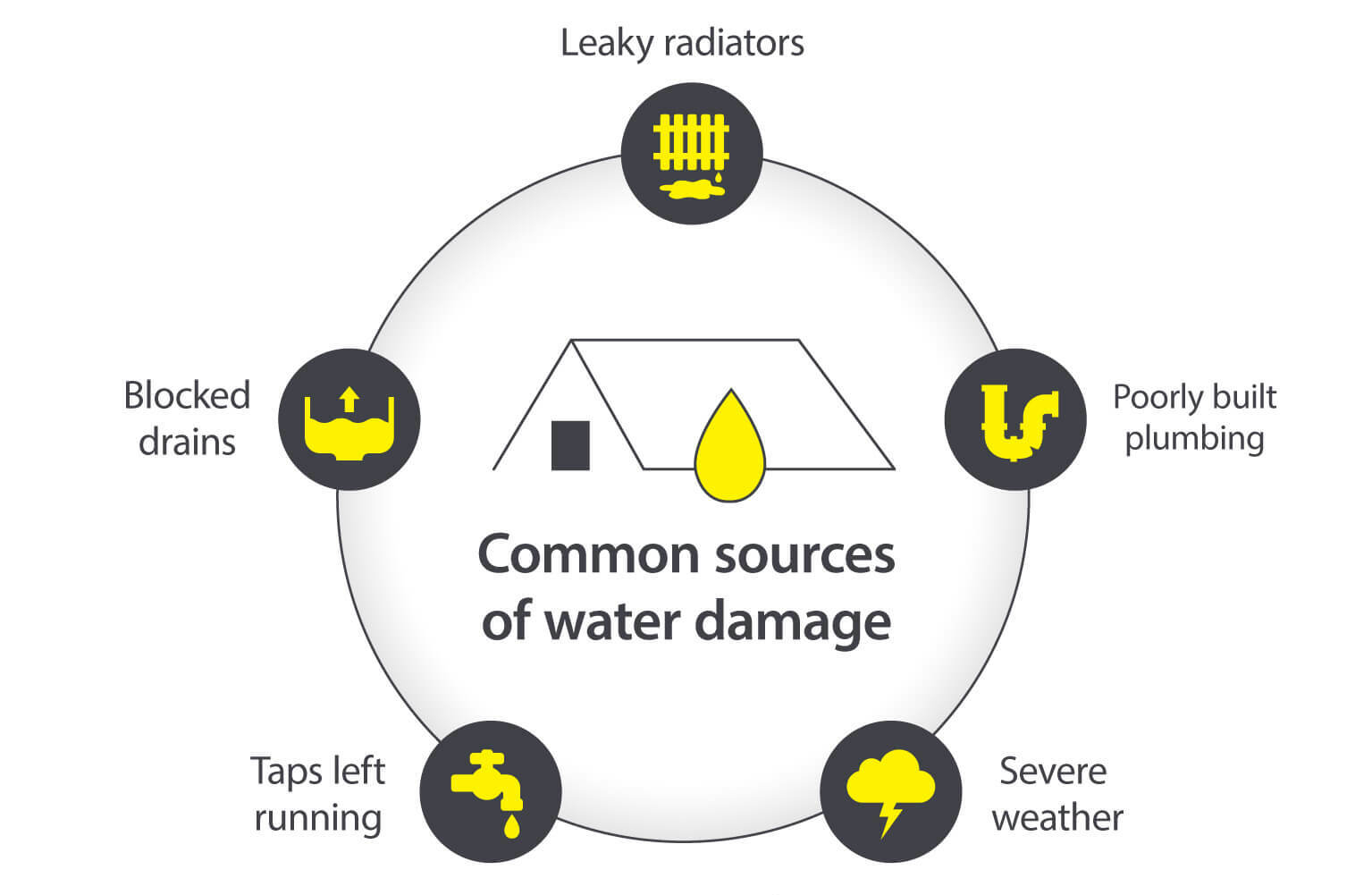

Water damage is something that over half (54%) of property owners throughout Europe have had to contend with at one point or another.

Moisture can seep into a property from the outside during heavy rain or flash floods. However, water damage can also originate from inside the properties themselves.

Oftentimes, this faulty plumbing goes unnoticed for days, weeks or even months before property owners realise their structure is damp. By this point, moisture has begun to take hold and will likely have penetrated deep into the fabric of a building, making drying a lengthier and more challenging task.

What damage can water cause?

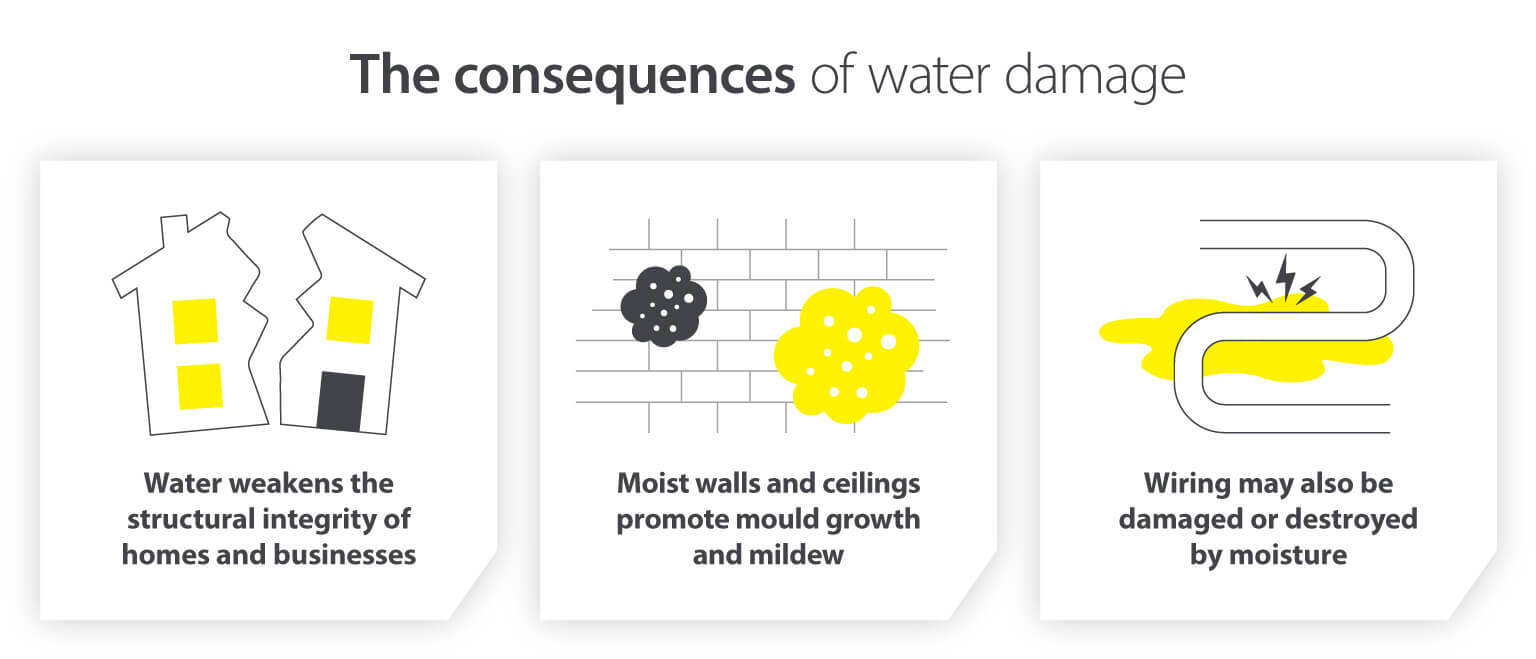

When water infiltrates the depths of a building and stagnates, this can cause extensive damage to floors, walls, and ceilings.

In turn, this will impact the time it takes to complete a project, as the more saturated a building is, the longer it takes to dry out and the more time professionals must devote to carrying out repair work.

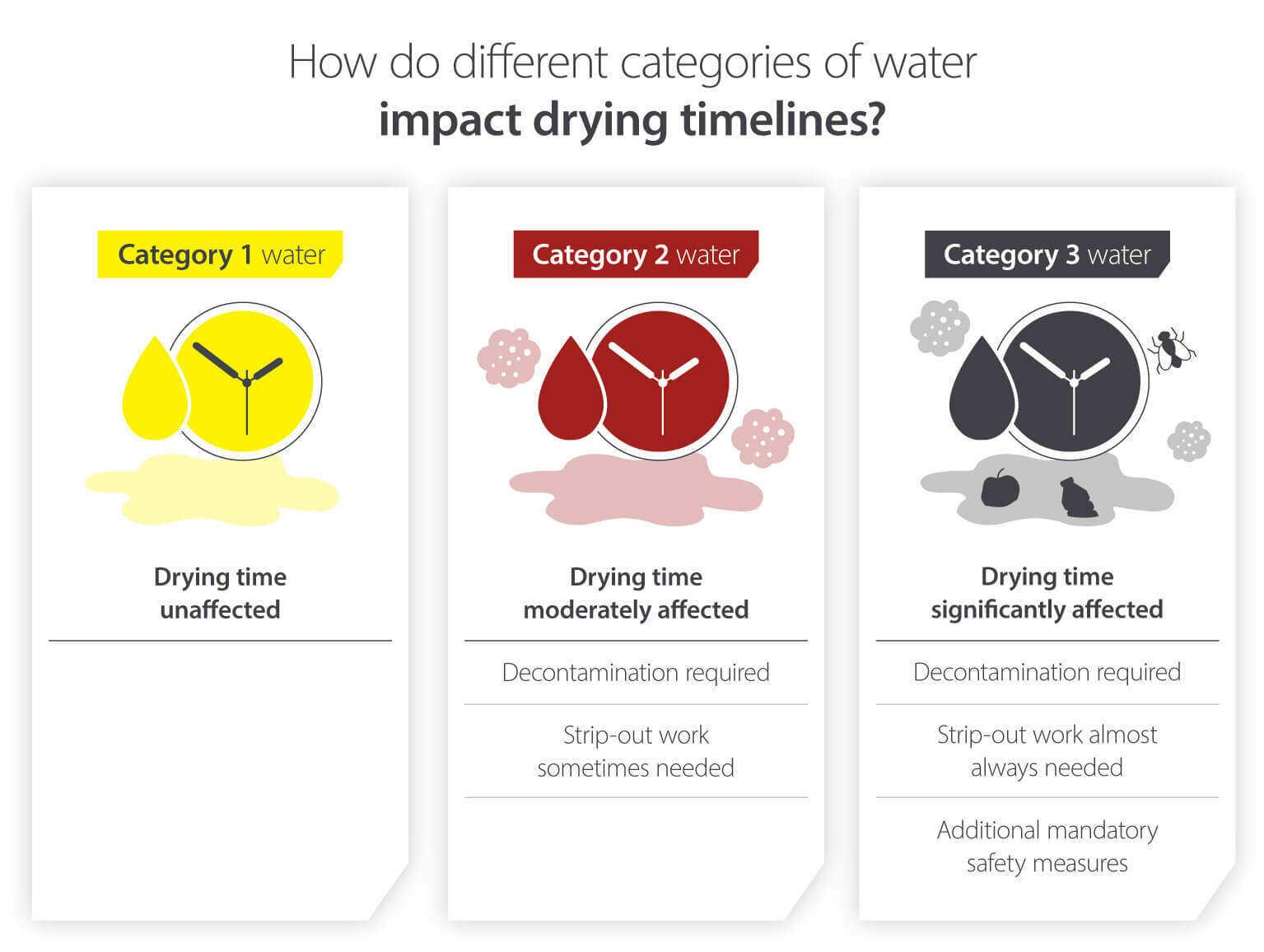

The category of water inside a property, defined by the Institute of Inspection Cleaning and Restoration Certification (IICRC), can also influence the type of water damage a building sustains and how long it takes to handle.

Category 1 water is the cleanest type of water damage, meaning it originates from a sanitary source, is non-toxic and free from harmful contaminants and bacteria. Examples of this include broken water supply lines, overflowing bathtubs and damage caused by rainwater.

Category 2, also known as greywater, can contain chemicals, bacteria and other pollutants that erode materials while also accelerating the growth of mould and mildew. This is therefore more harmful to living conditions and materials, requiring decontamination as well as drying to resolve.

Category 3 water, or blackwater, is often teeming with bacteria, oil, sewage and more, and accounts for all types of outdoor flooding. This presents the greatest hazard, as it not only dampens materials and encourages mould growth, but also creates a toxic indoor environment for residents and contractors.

The impact that these different categories of water can have on a project’s timeline can be significant. While category 1 water is the simplest and quickest type of moisture to remove, category 2 and 3 water complicates projects and will take longer to turn around.

This is because rooms containing stagnant water must be fully decontaminated before repair work can commence. Moreover, because these toxic substances are so dangerous, works involving this water almost always constitute additional strip-out work.

How to assess levels of water damage

To determine how long a structure will take to dry out, it is important to first assess the extent of the water damage. As a general rule of thumb, the more water there is, the more damage a structure will have suffered, and the longer it will take to fully dry.

Of course, it isn’t just the volume of water to bear in mind – the classification of water will also influence the severity of repairs needed, and the time and resources required to complete a drying job.

Because of this, calculating the time required to clean up water ingress can be tricky. To help, moisture detection meters are used to survey materials throughout a project to gauge ongoing progress.

There are also a handful of useful rule-of-thumb calculations that contractors can use when gauging the extent of water damage. Although they are rarely 100% accurate, these formulas can help professionals establish a rough time frame, and effectively restore a space.

How to dry water damage

When it comes to tackling water damage, the faster it can be dried out, the better. As a result, using the right technology and techniques is crucial when delivering an effective drying strategy.

Pressure drying

To completely dry wet walls, ceilings and floors that contain insulation, and remove excess water from inside a property, a dedicated pressure drying unit is a key component of any effective drying strategy. There are two common types of pressure drying methods.

Positive pressure drying

Positive pressure drying is a way of removing moisture from wet materials by blowing hot, dry air through structures.

More often than not, positive pressure drying is the fastest way to pressure dry a space. However, this technique is only suitable for well-ventilated or vacant environments and should be used in conjunction with air filtration solutions that are fitted with HEPA technology. This is because positive drying can potentially exhaust unpleasant or toxic particles, such as dust and mould, from wet areas into living spaces. With this in mind, we typically do not recommend this form of drying process unless the situation at hand specifically requires it.

Negative pressure drying

Negative pressure drying, on the other hand, uses suction power to vacuum moisture from within cavity spaces that contain insulation.

The process of drawing water out from the construction tends to take longer than alternate methods since less heat is applied to the construction. But, because this way of drying syphons unpleasant particles into the machine and passes them through multiple layers of filtration, these units create a safe and healthy indoor environment for residents and workers by removing airborne contaminants. This is ideal for buildings inundated with category 2 or 3 water and we would recommend this approach for all forms of insulation drying.

Dehumidifiers

When moisture is blown or vacuumed out from behind walls and floorboards, dehumidifiers prevent this exhausted water from condensing on surfaces again and causing additional damage. The dehumidifiers also create the dry air that is drawn into the interstitial spaces, replacing the moisture-laden air that has been removed. To do this there are two ways dehumidifiers can work.

Condense dehumidification

To capture moisture, humid air is drawn into the unit. This air is cooled, water is condensed from the air stream and then drained away, keeping indoor environments at a healthy humidity.

Harnessing the natural power of condensation to draw in and remove excess moisture in the air is highly efficient. However, this technique tends to capture and drain water slower than other types of dehumidification. As well as that, to work as efficiently as possible, conditions have to be warm – something that is not always possible, depending on where in the world this solution is deployed.

Adsorption dehumidification

Another way to lower indoor humidity inside water-damaged properties is to use adsorption dehumidifiers. This technology works by forcing air over desiccant materials inside the machine that attract and retain water.

Generally, adsorption dehumidification is often the faster way to dehumidify a space. However, this extra speed carries with it additional energy usage and operating costs.

Plus, even though these devices thrive in a wide range of temperatures, many units cannot operate in hot environments above 35°C.

You can discover more on the ‘rules of thumb’ to follow for the effective use of dehumidifiers in water damage restoration projects here.

Increased ventilation

Another way to reduce the presence of excess moisture in a home or business is to increase ventilation in affected areas. Anything from opening windows in the affected rooms to using air movement devices will help increase air flow and facilitate the drying process.

Even though drying through ventilation alone is slow, it can be used in conjunction with a property’s central heating to support the restoration process.

However, it is important to employ a dehumidification solution alongside increased ventilation to ensure that the water that evaporates from damaged materials is captured, and not allowed to condense back on surfaces or objects once the air circulation ceases.

What is the best way to handle water-damaged buildings?

To rid structures and buildings of water as fast and effectively as possible, the optimal setup involves taking a balanced approach to drying.

When dehumidifiers and pressure dryers are combined with fans and heaters, the potential for mould growth can be reduced, water inside structures is removed and living conditions can be restored quickly.

However, the fastest solution may not necessarily be the best for every drying project.

Using the most powerful technology together can be costly, energy-intensive and disruptive for home or business owners

Some structures, such as older homes and listed buildings, are more fragile than others. To prevent causing further damage, a slower, gentler drying method is ideal

More powerful equipment is often large and loud, making it difficult for residents to live day to day while drying works continue

For this reason, it is crucial to carefully select a unit best suited to the job at hand. A device that may be suitable for a large office building or basement may not be appropriate for water damage in a bathroom, bedroom or living room, for example.

Our experts at Aerial realise this, which is why we offer a wide range of drying units for a number of different scenarios. Whether the job is drying a centuries-old home gradually, or getting a business back in action quickly following a flash flood, you will always find a capable, effective solution across our extensive selection of units.

Read our article on determining the best mobile dehumidifier setup for further insight into the different approaches to drying water damage and how to select the most appropriate solution for your requirements.

Dry with confidence; talk to the experts

Every drying project is unique and the time it takes to complete each job can be difficult to estimate. To help, tools like moisture meters can monitor daily drying progress and give teams an idea of how the job is going and when work can wrap up.

Although it can be difficult estimating project timelines, acting fast is critical when water gets in. To hasten the drying process and limit water damage, employing the right technologies and techniques is vital. However, haste should never come at the expense of quality.

We understand that speed isn't always the objective of a drying project. That’s why we offer a variety of different units for numerous scenarios – all delivering the portability, ruggedness and control required on restoration projects.

Each of our machines leverage the latest technology and meets the highest standards of performance, efficiency and reliability.

To learn more about all of our water drying units and how they can benefit your professional water damage restoration company, get in touch today.

Related products

Featured insights

Top tips for drying out buildings

Expert advice for your next project

How negative pressure drying allows for targeted, safe drying of water-damaged buildings.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.