How Italy’s top winemakers control humidity from vine to cellar

- Home

- Insights

- Humidity control and drying insights

- How Italy’s top winemakers control humidity from vine to cellar

Even if you’re not a wine connoisseur, you may well have heard of Valpolicella, or at least, Amarone, the wine that makes the area famous. Its popularity has been on the rise since 2009 when it earned DOCG status (Italy’s official top-tier wine classification). Producers in the area have even a signed manifesto to ensure the high production standards are passed from generation to generation.

In this article, you’ll discover how dehumidifiers can be a wine buff’s best friend by protecting their favourite drop from fluctuating conditions in both production and storage.

Bringing modern technology to an ancient process

Just North of Verona, the Valpolicella region is home to lush valleys, breathtaking lakes and one of the most prestigious wine making traditions in the world. Refined over 25 centuries, wine makers in the area use an ancient technique of harvesting and part-drying three kinds of grape.

At the beginning of the process, the grapes are separated and either pressed immediately or left to dry over ventilated wooden grids. Several months into the vintage, a unique type of mould growth and the loss of humidity improves their sugar content and allows them to develop their distinctive flavours before being pressed.

As the food and beverage industry has evolved, Master dehumidifiers, manufactured in nearby Pastrengo, have been helping expert wine makers perfect their craft by maintaining optimum humidity levels in caves, cellars, basements and factories. As they become more widely used, dehumidifiers and drying rooms have helped producers reduce their wine’s alcohol content, without losing the powerful character that makes it so drinkable.

How it works

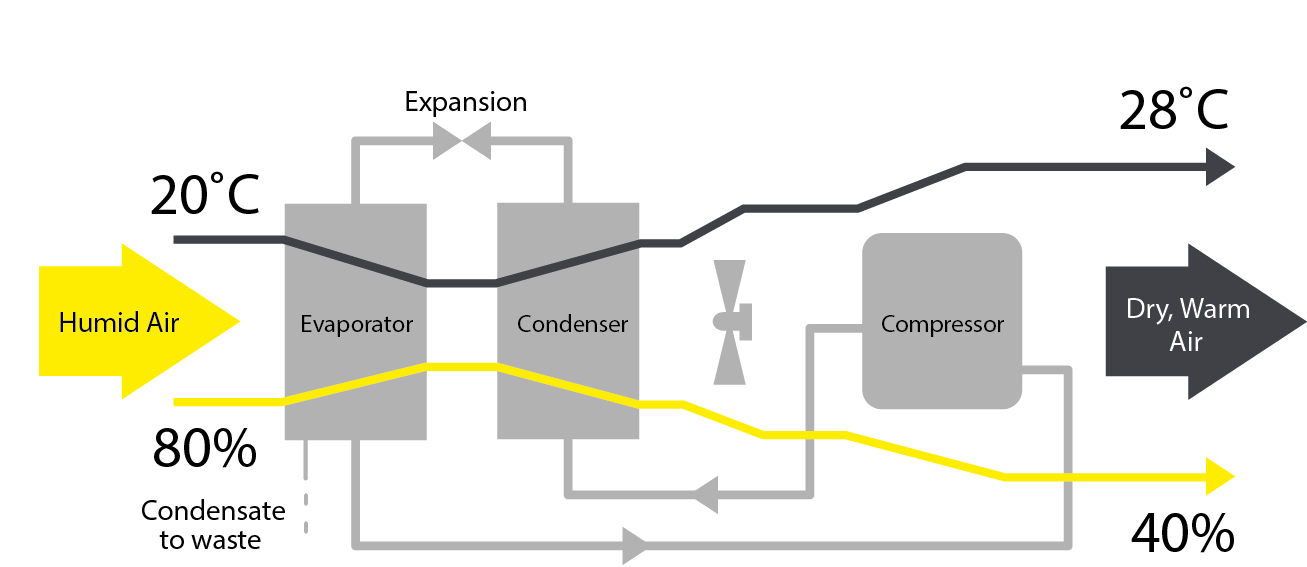

In spaces with little ventilation and fluctuating temperatures (i.e wine cellars), stable humidity levels can’t be achieved using heating alone. When a space is sealed off from outside elements, condensation dehumidifiers create a continuous air flow while removing moisture and keeping humidity levels in check.

Damp air is drawn into the dehumidifier and across a refrigerated coil

The air is cooled below its dew point, condensing the water vapour

Latent heat energy is recovered and re-used

Cooled air passes across the condenser and reheated

The warm dry air is then returned to the room at the required humidity

Keeping wine cellars safe from humidity

Humidity will continue to affect the taste and quality of wine long after production, yet it’s an often overlooked part of a wine cellar. As a rule, bottles should be kept between 60% and 70% relative humidity.

When humidity levels are too high (above 70%)

Labels begin to deteriorate and mould starts to form inside the bottle.

When humidity levels are too low (below 60%)

Corks will begin to dry out, exposing your wine to the air and causing it to lose its taste and aroma.

How you can protect your produce

Master condensing dehumidifiers have all kinds of benefits in the food and beverage industry.

You might find them regulating conditions and protecting produce anywhere from farms to freezer rooms. But for every application, a bespoke set up is crucial for getting the best from our products. We can help you determine your requirements, work out the capacity you need and help you install them where they'll do the most good.

For extra peace of mind, you’ll also have expert support from an in-house applications department and international service network. Get in touch with our team to find out more about our commercial dehumidifiers.

Related products

Featured insights

How heaters help certified cleaning companies sanitise food tanks

Flexible heating for animal keeping and drying and storage of produce

Learn how effective climate control solutions can support the need for sustainability in the food industry.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.