How evaporative coolers can improve the efficiency of your air handling unit

- Home

- Insights

- Cooling insights

- How evaporative coolers can improve the efficiency of your air handling unit

In this article, we discuss how evaporative cooling can be used alongside air handling units and the savings that can be made by combining these technologies.

While it often takes a significant amount of time and energy for large spaces to warm up, when they do get hot, it is just as hard to cool these spaces down.

Excessive heat is not just a source of discomfort for workers – it also poses a risk to health, especially in physically demanding environments such as factories and warehouses. Dangerously high temperatures can have a range of unwanted outcomes, including:

Dizziness

Heat exhaustion

Dehydration

Heat stroke

To prevent heat from outdoor weather, machinery and people from building to unsafe levels in large facilities, air handling units (AHUs) are installed to circulate cool, fresh air throughout the building and reduce the temperature.

While air handlers are incredibly effective at controlling the indoor climate in large facilities, they can be paired with evaporative cooling units to deliver the same cooling power in a more energy-efficient package.

What is an evaporative cooling unit?

An evaporative cooling unit is a type of air cooler that harnesses the natural power of evaporation to cool the air quickly and cost-effectively.

To do this, these machines draw in air from the outdoors and force it through a damp cooling pad. When this warm air comes into contact with the wet membrane, moisture is evaporated along with some of the heat energy, producing a cooling effect.

How can an evaporative cooler help air handling units cool air?

Evaporative coolers are an effective, economical and environmentally friendly way of reducing the air temperature.

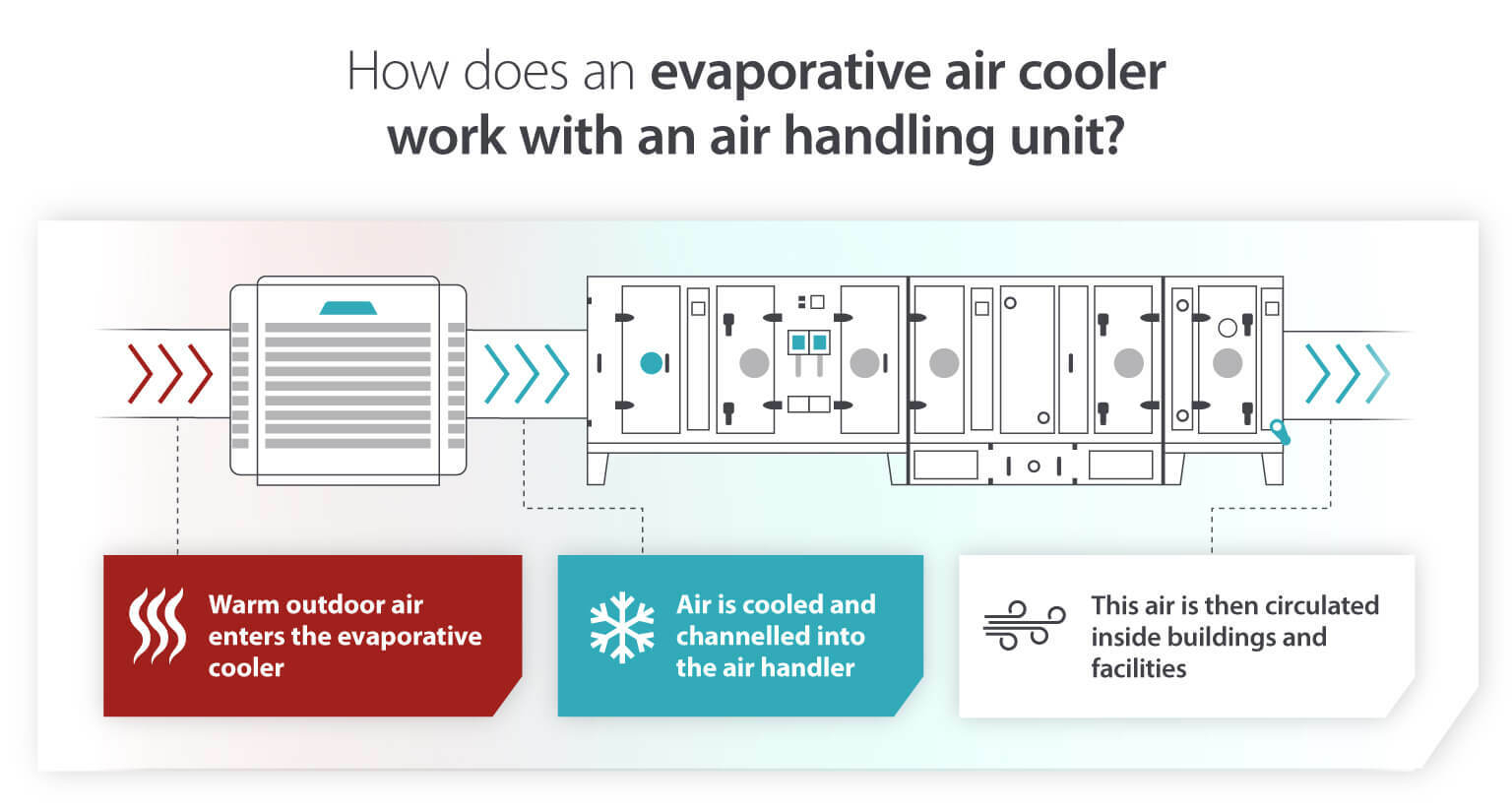

By harnessing this technology to efficiently pre-cool air before it enters the air handling unit, the AHU itself does not have to use any energy to lower the air temperature, and can immediately distribute it throughout the facility.

As well as reducing the costs associated with operation, the combination of both technologies works to increase energy efficiency by reducing the power needed to reach and maintain comfortable conditions inside.

In addition, evaporative units reduce the environmental impact of cooling. This is because these systems harness the natural properties of evaporation and use only water to reduce the temperature.

What settings are ideal for evaporative units?

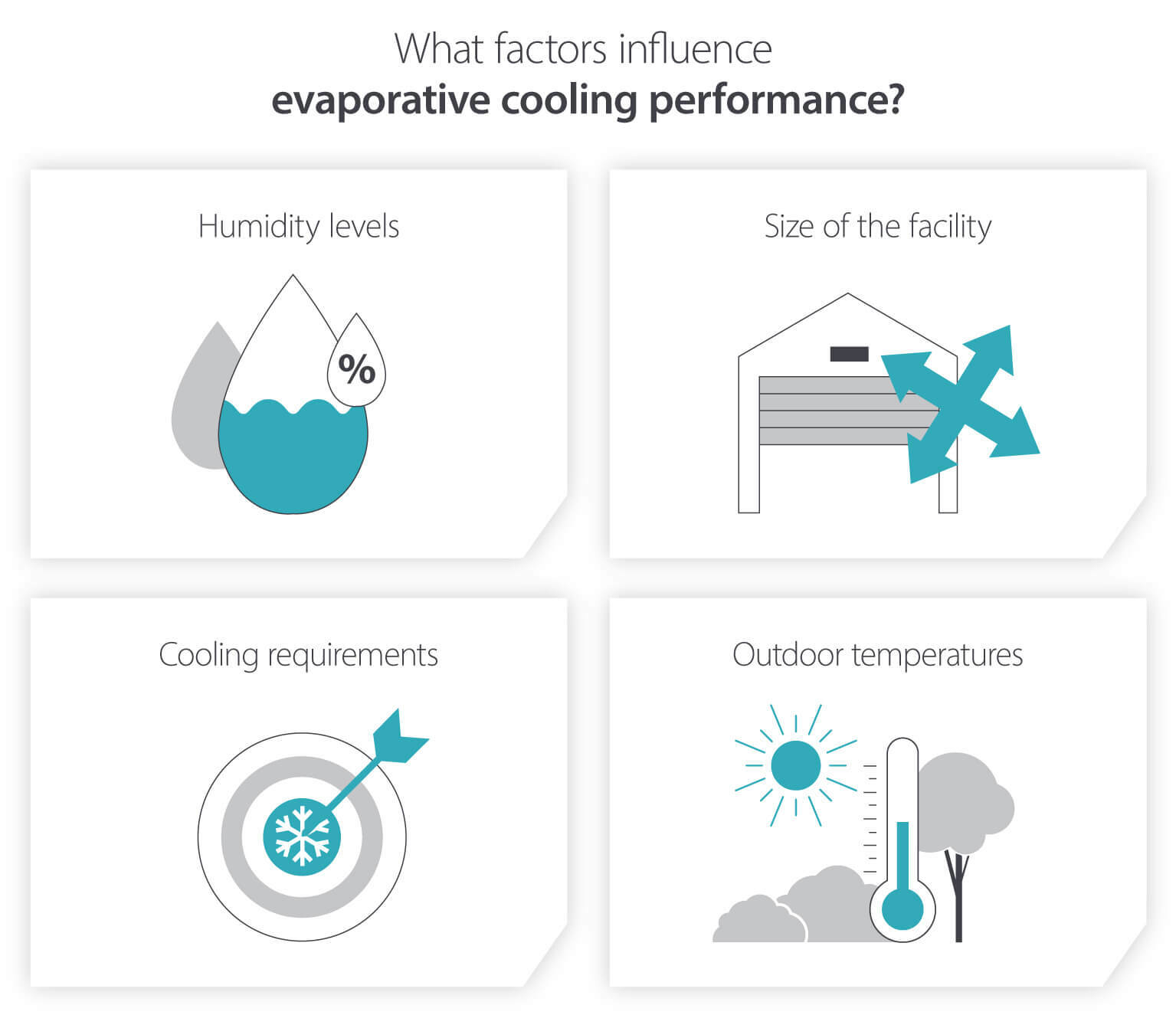

Because evaporative technology operates most efficiently in warm and dry climates, countries that share these traits are ideal environments for these machines.

However, this does not mean that moderate environments are unsuitable for this equipment. Countries with cooler and more humid climates can also benefit from this technology with just a small impact on efficiency.

Furthermore, facilities that do not need to keep temperatures at a precise, fixed level at all times are better suited for an evaporative cooler. This is because these units rely on the outdoor weather to provide cool air, and can fluctuate with changing conditions.

This means structures that are legally obliged to keep conditions at precise levels, such as pharmaceutical labs, may not be ideal for this type of commercial air cooling solution.

Instead, by combining both air-conditioning systems and evaporative units, operators can ensure there is always a stream of cool air reaching the air handler, regardless of outdoor conditions.

Utilising a dual cooling solution can allow large facilities to deliver precise conditions 100% of the time, while simultaneously reducing power consumption and CO2 emissions by as much as 70%.

Factors to consider when using air handlers and evaporative coolers together

In order for air handling units to work as efficiently and effectively as possible with evaporative coolers, it is crucial to bear in mind the flow of air from one unit to the next.

If pre-cooled air from evaporative units is not channelled directly into the air handler’s intake, this air may escape and waste energy.

Moreover, if the air handler does not receive air at the correct temperature, the system will need to expend more energy to cool it further. This will add to the entire system’s power draw, impacting efficiency and running costs.

When opting for a combined commercial air cooling solution it is important to also consider the following factors:

To learn more about the optimal configuration for air handling units and evaporative coolers, speak to the experts at Biocool. Our specialised engineering team can provide advice and assistance with sizing and installation.

What kind of savings can be made?

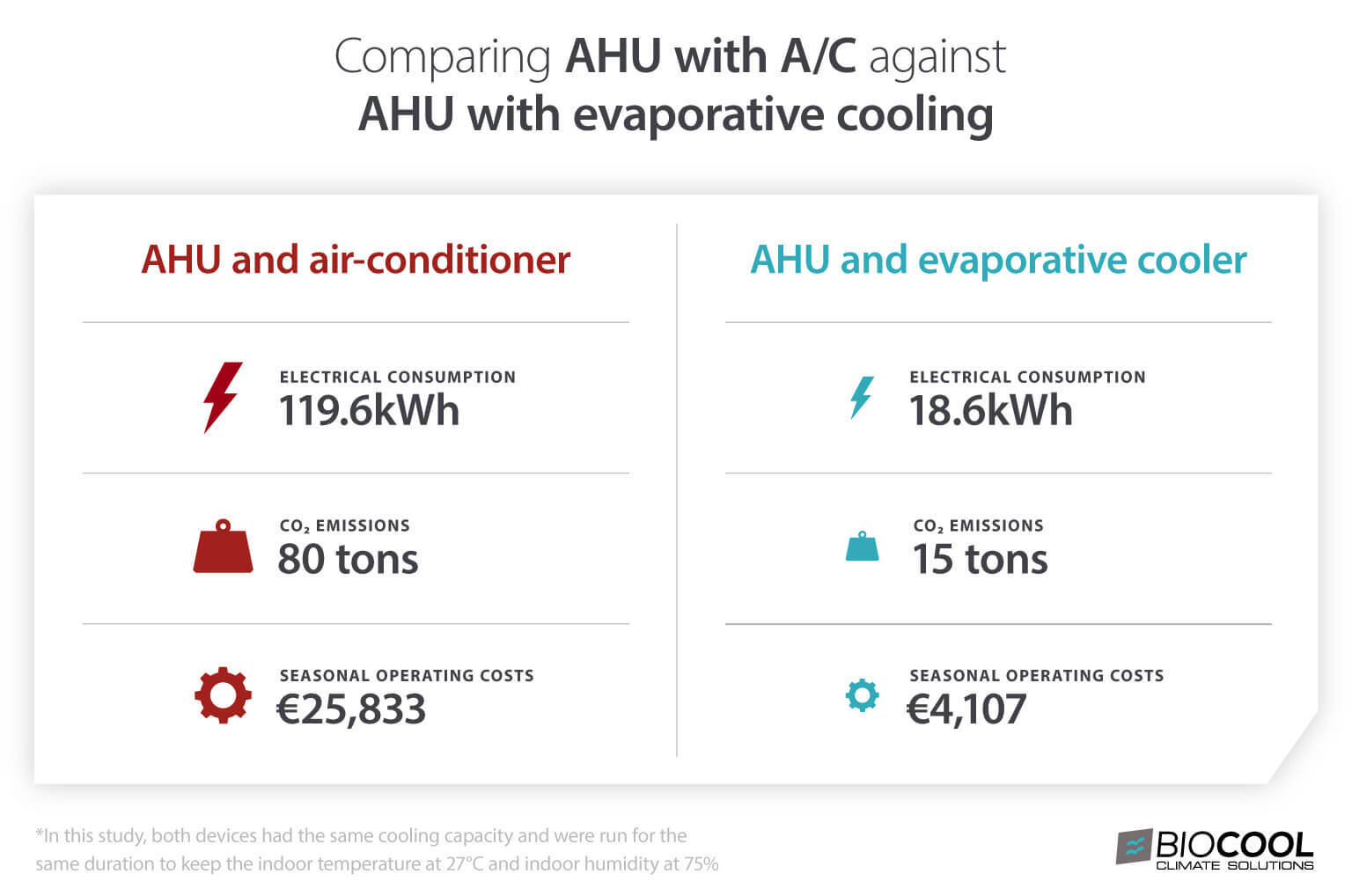

Because every setup is unique it is difficult to quantify the specific savings you could make with a combined system in your facility.

Instead, to demonstrate the potential savings a solution like this can make, consider the following example:

In this example, Client A installed a Biocool BIO 30AV evaporative cooler to work alongside their AHU.

After over 1,000 hours of operation, the organisation was able to significantly reduce its energy consumption, environmental impact and operating costs, when compared to a similarly sized air-conditioner and air handling solution.

In this example each system was of a similar capacity, was run for the same duration and used in the same setting to achieve identical interior conditions.

What evaporative cooler is ideal?

While the fundamental principle remains the same in all evaporative units, not every model is built equal. Choosing an effective cooler is critical to the efficiency of your cooling process, so it’s important to select a unit capable of meeting your needs.

Biocool is a world leader in reliable, sustainable and efficient air cooling solutions. Our range of evaporative cooling units harness over 20 years of experience and help facilities all over the world deliver optimal conditions with unmatched energy efficiency.

Integrated ozone technology works to eliminate the presence of microbes within the internal reservoir

Pre-filters help remove unwanted pollutants from entering the system to maximise air quality during operation

To ensure peak cooling efficiency, even amounts of water are distributed throughout the integral cooling pads continuously throughout the day

Remotely operate up to ten evaporative units at a time with ease using the Smart City Cooler Controller.

Start saving with efficient commercial cooling systems

If you would like to learn more about Biocool evaporative cooling technology, and how it can be utilised to enhance the energy efficiency of your commercial cooling system, speak to our expert team or fill out the form below.

Related products

Featured insights

Evaporative cooling is key for climate control now and in the future.

Airborne viruses are a threat to our health – how can Biocool help?

The multi-purpose power of Biocool’s evaporating cooling systems.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.