How dehumidifiers help the RAF perform at their best

- Home

- Insights

- Humidity control and drying insights

- How dehumidifiers help the RAF perform at their best

Being in the RAF takes dedication, intensive training and the readiness to handle any situation on land, sea and air. When there is no room for error, you need to be 100% confident in the clothing and equipment you are relying on.

Being in the RAF takes dedication, intensive training and the readiness to handle any situation on land, sea and air. When there is no room for error, you need to be 100% confident in the clothing and equipment you are relying on.

For military and aerospace training facilities like RAF St Mawgan and HMS Raleigh in the UK, the drying of kit between exercises needs to be fast, efficient and reliable.

That’s why both facilities have dehumidifier-powered drying rooms in constant use. Even when the rooms are full, wet equipment ranging from survival suits and protective clothing to dinghies and life-rafts can be dry and ready for action within 24 hours.

Dehumidification is the only solution

Before the drying room was installed, equipment at RAF St Mawgan was left outside to dry and, unsurprisingly, it would rarely be ready in time for the next training session and disrupt scheduling. A common attempt at speeding up the drying process during winter is to turn up the heating, but because warm air is able to contain a higher moisture content, humidity remains in the room and in some materials. If the temperature drops, condensation is likely to form, which will actually slow down the drying process (and result in some expensive energy bills).

RAF St Mawgan worked with Calorex to install three refrigerant/condensation dehumidifiers across their drying room facilities. Unlike heating, dehumidifiers re-circulate air throughout the room while physically removing moisture from the air and, in turn, reducing humidity levels. In comparison, Calorex dehumidifiers can reduce energy costs by up to 500% by converting every unit of energy they use into 2.5 times that amount in usable heat.

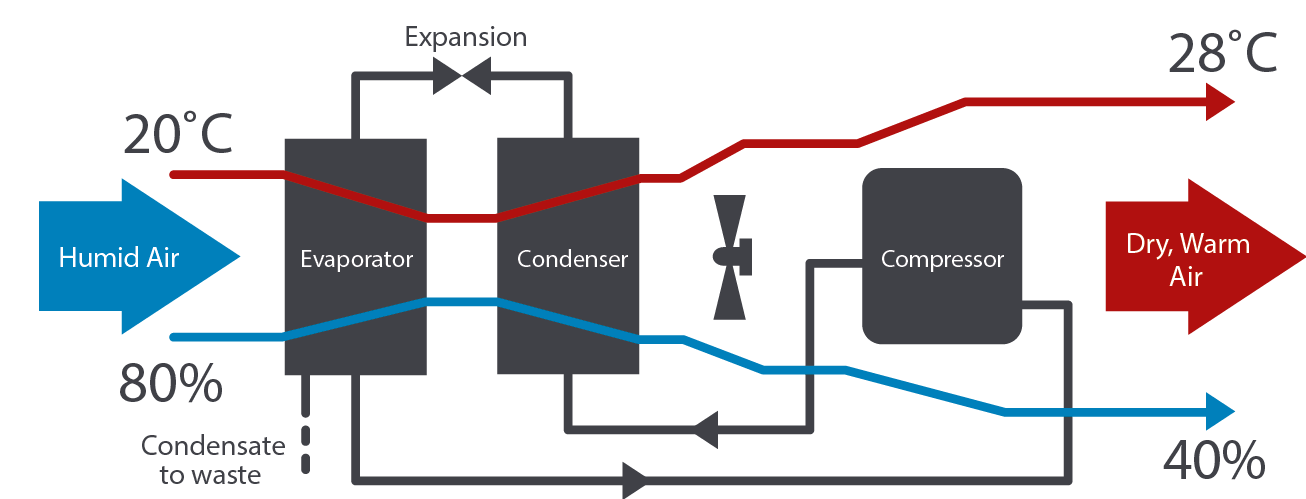

HMS Rayleigh is also seeing the benefits of drying efficiency in its sea survival training facility, where wetsuits need to be thoroughly dried between sessions. With the drying room temperature set between 25°C-30°C they use a dehumidifier on a 14 hour cycle between 5pm and 7am. Here’s how it works:

Damp air is drawn into the dehumidifier and across a refrigerated coil

The air is cooled below its dew point, condensing the water vapour

Latent heat energy is recovered and re-used

Cooled air passes across the condenser and reheated

The warm dry air is then returned to the room at the required humidity

Key benefits of Dantherm Group dehumidifiers:

High performance level, even in unheated rooms

Powerful centrifugal fan

Professional hot gas automatic defrost

Automatic hygrostat controlled dehumidification

Can connect to an external condensation drain or condensate pump

Self contained

With wall-mounted or free-standing options, we can help you install a tailored dehumidifier set up that can turn almost any room into a drying room for all kinds of equipment. The installation process is quick, simple and causes minimal disruption.

And, for extra peace of mind, all our products come with expert support from an in-house applications department and international service network.

Get in touch with our team to find out more about our reliable commercial dehumidifiers to see how they can help you.

Related products

Featured insights

Why a drying room can be a game-changer for outdoor pursuits centres

Protect your staff and streamline productivity.

Discover why drying room dehumidifiers are so important for emergency services, and how to choose the right solution.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.