How dehumidification is modernising Norway’s fishing industry

- Home

- Insights

- Humidity control and drying insights

- How dehumidification is modernising Norway’s fishing industry

Effective climate control can transform the approach of Norway’s fisheries and help the industry to process more fish over a shorter period of time, reduce energy consumption and easily adhere to strict hygiene standards. In this article, we explore why industry knowledge is crucial to finding the right dehumidification solution for any fishing facility.

Since the 1970s, fisheries have been a growing industry in Norway, and today aquaculture is thriving – with the country supplying €12-13 billion worth of fresh fish to countries across the world every year.

Norway boasts over 21,000km of coastline and some of the most ideal climatic environments for at-sea fish farming, so there are already huge expansion opportunities for fisheries, but these can only be harnessed if existing indoor butchery, filleting and processing methods can be enhanced – and other more sustainable methods are introduced. This is where dehumidification and total climate solutions can help.

A growing trend in Norway has also seen some companies open more full-sized fish farms indoors in an attempt to reduce the environmental pressures and impact on the ocean. This means that some businesses are managing farming, butchery, filleting and processing in locations where climate control is crucial.

While the majority of fisheries remain at sea, the industry is still facing challenges when it comes to achieving consistent indoor climates during the different stages of processing. Ensuring that temperatures, humidity and air quality is calculated and maintained correctly is paramount to hygiene, food quality and processing efficiencies.

How can climate solutions benefit fisheries?

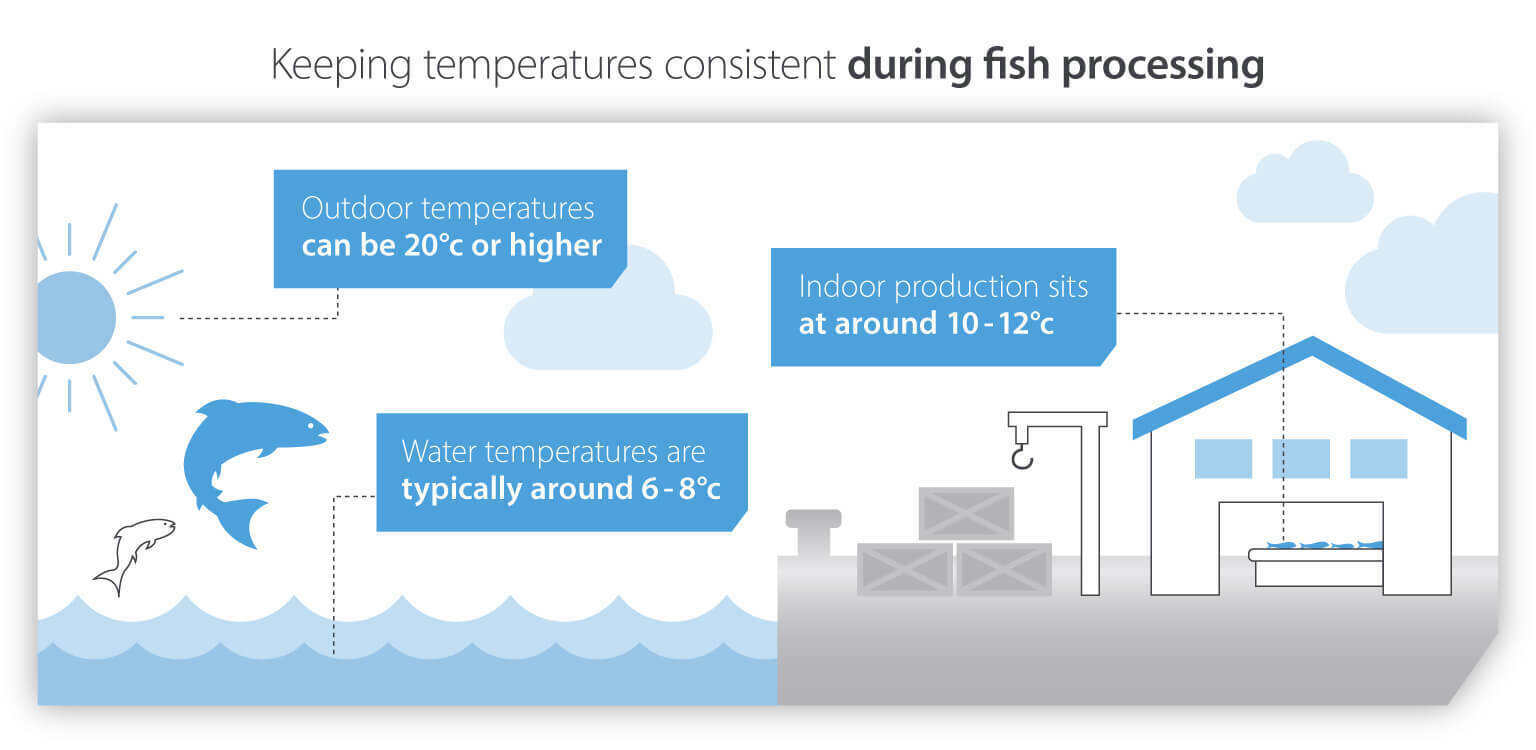

When fresh fish is farmed, water temperatures are typically around 6 - 8°C, whereas indoor production sits at around 10 - 12°C, despite outdoor temperatures of 20°C (or higher). In the summer months, when outdoor temperatures are even greater, climate solutions are even more critical to keep these environments under control.

Bringing fish at a lower temperature into a warmer environment can leave the air vulnerable to the process of condensation, creating unwanted moisture, unhygienic conditions and irregular temperatures.

Furthermore, there is a significant amount of cold water used during processes, such as washing produce. So, it is not just air temperatures affecting the humidity in fisheries, but the cold water can lead to condensation forming throughout these settings.

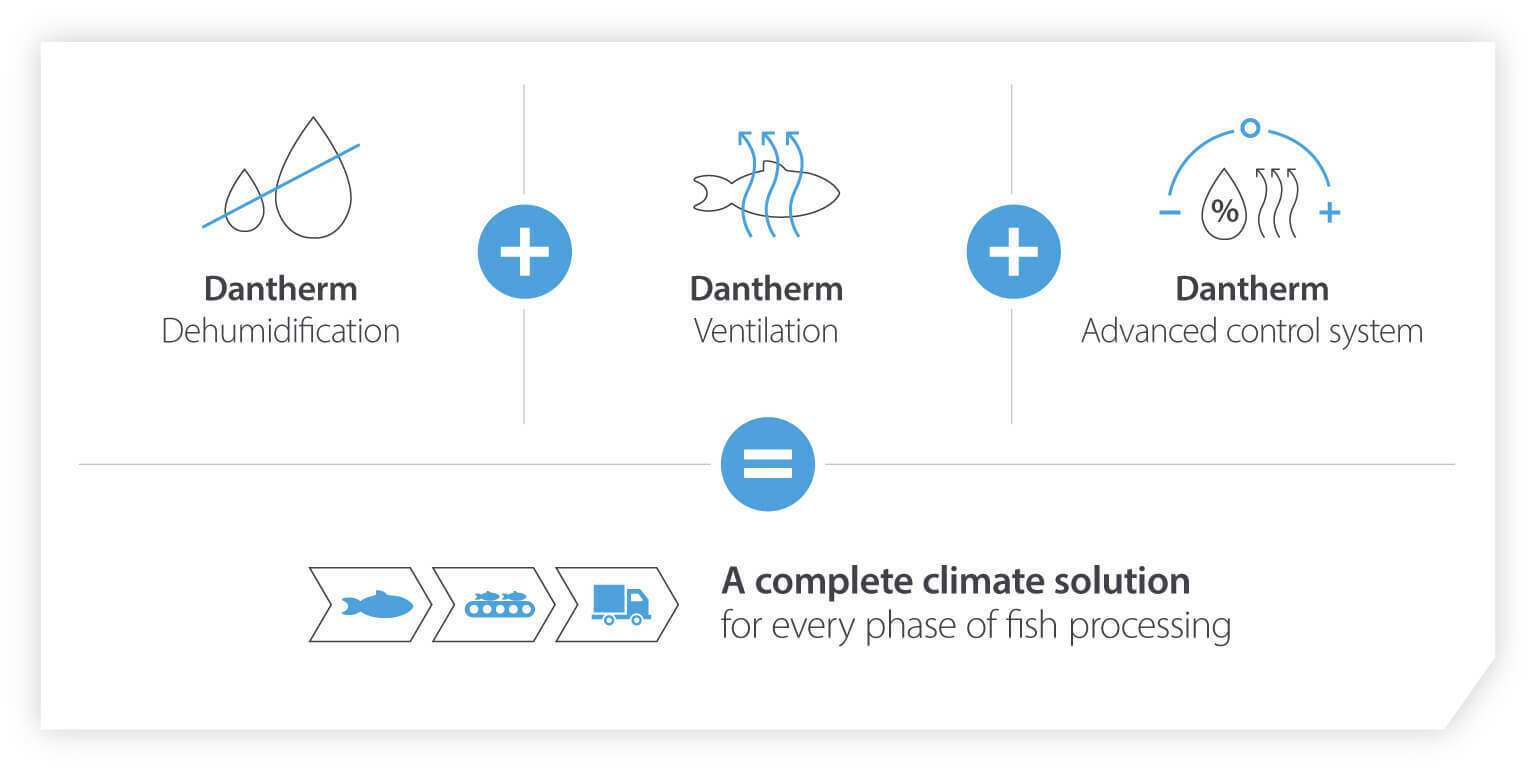

Precise dehumidification and ventilation systems allow for controlled climatic environments, ensuring that temperatures, relative humidity and fresh air levels are correct for the respective stages of fish processing. The right combination of dehumidification and ventilation solutions can provide the following benefits to your facilities:

#1 Accurate air quality control designed specifically for your facility

We use a combination of Dantherm desiccant dehumidifiers and Dantherm ventilation and control systems to provide a bespoke solution to your needs. Complete climate control is achieved by analysing the design and size of your space, and its varying uses and applications.

#2 A ‘mode’ for each stage of processing

Once we have worked out the complicated details, we can deliver systems that are specifically programmed to fit your ‘modes’ and phases of processing. This will not only support a healthy environment for the fish, but also create a better working space for employees.

#3 Control condensation during the washing phase

The need to wash down areas after handling fish is essential for good hygiene and to follow strict guidelines. In these instances, there is a huge need to maximise ventilation to ensure that there is a consistent supply of fresh air.

#4 Dry more quickly and effectively

The special combination of ventilation and dehumidification allows for fast and effective drying between production phases. If the relative humidity is too high before the next phase of processing, the climate becomes full of moisture, uncontrolled and unhygienic.

The more controlled you make the environment, the quicker you can get back to processing and process more fish. This can lead to substantial cost savings - for example, with faster drying processes, the next shift can start sooner, allowing more work to be completed.

Dantherm Group dehumidifiers and drying systems are fit-for-purpose and widely used in a range of building drying applications.

#5 Better for the environment

In fish factories, there tends to be high usage of cooling equipment which generates a lot of heat. What the Dantherm desiccant dehumidifiers, Dantherm control and DanX systems do is take this heat and reuse it to avoid waste and maximise energy preservation.

#6 Save time, money and effort

We are able to make the dehumidification and ventilation solutions more precise, more effective and more controlled. Manual cleaning is time-consuming. Alternative drying processes are costly. Energy consumption can be through the roof without the right system in place. We ensure your facility provides the best environment for production and employees to thrive.

What makes Dantherm the ideal partner

This application requires a lot of air flow, particularly during the drying process. We combine Dantherm desiccant dehumidifiers and Dantherm ventilation and control systems to create a complete solution.

The DanX system helps to keep the air inside the building consistent and ensures fresh air is continually flowing. Our Dantherm desiccant dehumidifiers help to control the relative humidity and keep it at the optimal level.

The DanX system was originally developed for very harsh commercial pool environments, so can withstand lots of different climates.

For every company interested in our technology, we provide a dedicated analysis of their environments and its usage before recommendations are made. For over 30 years our experienced engineers have been working with dehumidification. We can calculate the exact systems needed for the size and temperature objectives of any fishery or production facility.

We are the only company in Norway that works the way we do, and can provide these complete climate control solutions. We use a combination of these solutions to ensure our customers have better production control, tighter processes and low energy consumption.

Before you purchase any system, ensure you understand the return on investment you can achieve with Dantherm climate control solutions for the food industry. Our team will be happy to talk you through it.

Speak to the experts in climate control technology – contact us using the form below.

Related products

Featured insights

Find out how the Dantherm ECOline is achieving incredible energy savings for fish processing plants.

How climate plays the decisive role in cannabis production

How does relative humidity affect your facility?

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.