Don’t let humidity derail your construction project

- Home

- Insights

- Humidity control and drying insights

- Don’t let humidity derail your construction project

Modern construction projects have to work to increasingly tight deadlines. However, the drying processes of materials such as screed flooring, plaster, paint and concrete take time. While it’s not advisable to rush these vital stages of a build, they can be helped along by optimising humidity levels.

In this article, you will find out why unwanted water vapour is such a challenge and how portable dehumidifiers can have a pivotal role in keeping construction timelines on track.

How can humidity put a stop to progress?

In cold climates or poorly ventilated spaces, the atmosphere can quickly become saturated with moisture from various drying processes during a construction project. This, in turn, affects the relative humidity of the environment. Relative humidity (RH) is the amount of water in the air in relation to how much it could hold at its current temperature.

As the air fills with water vapour, drying times of paint and plaster are prolonged while screed and concrete can be prevented from settling at optimum moisture content. When humidity is left to linger, you could be left with a host of costly and time-consuming issues, including:

Ineffective flooring adhesive

Efflorescence

Structural weakness

Mould and mildew

Uneven finishes

Adding heat will speed-up drying, but because it only reaches what’s on the surface, it is a method that’s likely to cost you more in the long-run. By force-drying, heat can lock moisture inside building materials and increase the risk of cracking and distortion to walls, doors and ceilings.

By investing in a dehumidifier, you can physically remove moisture from the air. Portable units from Dantherm Group recirculate humid air, drying it out as it passes through their systems. This warm, moisture-free air is then returned to the room to continue the process.

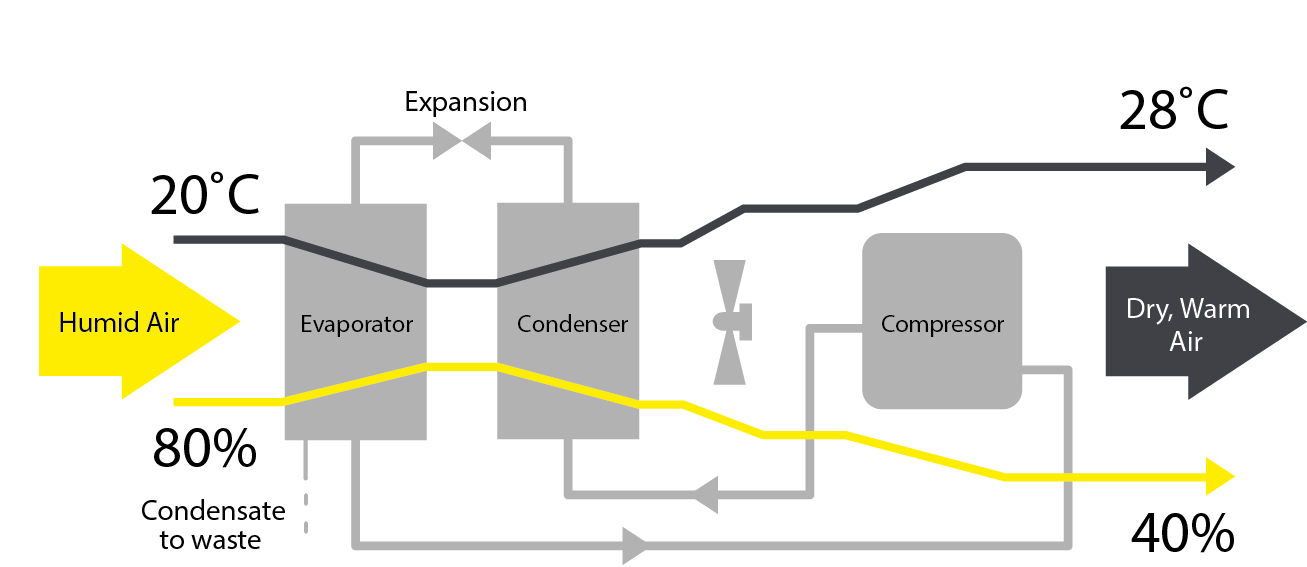

How condense dehumidification works

Damp air is drawn into the dehumidifier and across a refrigerated coil

The air is cooled below its dew point, condensing the water vapour

Latent heat energy is recovered and re-used

Cooled air passes across the condenser and reheated

The warm dry air is then returned to the room at the required humidity

Key benefits

Low energy consumption

Minimal maintenance required

High specific moisture extraction (kg/kWh)

Easy installation

Small diameter condensate drain

How to get the best from your dehumidifier

Every construction project will have its own unique requirements, but following the checklist below is a useful place to start.

1. Capacity

A dehumidifier’s capacity is rated by the amount of moisture it can remove in 24 hours. One way to work out the right capacity for your project is to determine how much moisture you need to remove and the amount of time you have to do it.

2. Ventilation

To prevent wet weather and humid air from outside slowing down your drying processes, keep the space as sealed as possible.

3. Positioning

Below-ground rooms like cellars, and areas where painting and cement mixing is taking place usually have the highest humidity levels. Make sure you place your dehumidifiers where they’ll do the most good.

4. Remote monitoring

To keep track of progress and make sure your dehumidifier isn’t switched off when you’re not on-site, remote monitoring systems use a cloud-based sensor to send status updates to your computer. It will also switch-off the system as soon as drying is complete, so you will only be paying for the energy you need.

Master dehumidifiers are built to handle the tough working conditions of the construction industry and come with expert support from an international service network.

If you need humidity control or drying solutions for the construction sector, view our range of commercial condensation and adsorption dehumidifiers.

For help choosing the right system for your project, don’t hesitate to get in touch with our team.

Related products

Featured insights

Discover the different methods to dehumidify building sites quickly and cost effectively

Don't let harmful moisture take your building back to square one

Removing the risk of dust during building work and renovations

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.