Breathe easy: How to get rid of construction dust in the air

- Home

- Insights

- Air cleaning insights

- Breathe easy: How to get rid of construction dust in the air

As building materials are removed, cut, and fitted, dust can quickly spread indoors. The use of high-energy tools such as cut-off saws and grit blasters, as well as techniques like dry sweeping, also tend to produce significant amounts of dust.

These particles are inevitable on practically any home renovation project, and can present a real risk to employees. To create a safe, healthy environment, construction dust should be managed diligently, like any other hazard.

Below, we discuss why it is important to remove dust during construction work, the challenges associated with this unique contaminant, and how to effectively remove it to preserve on-site air quality.

Why is it always important to remove construction dust?

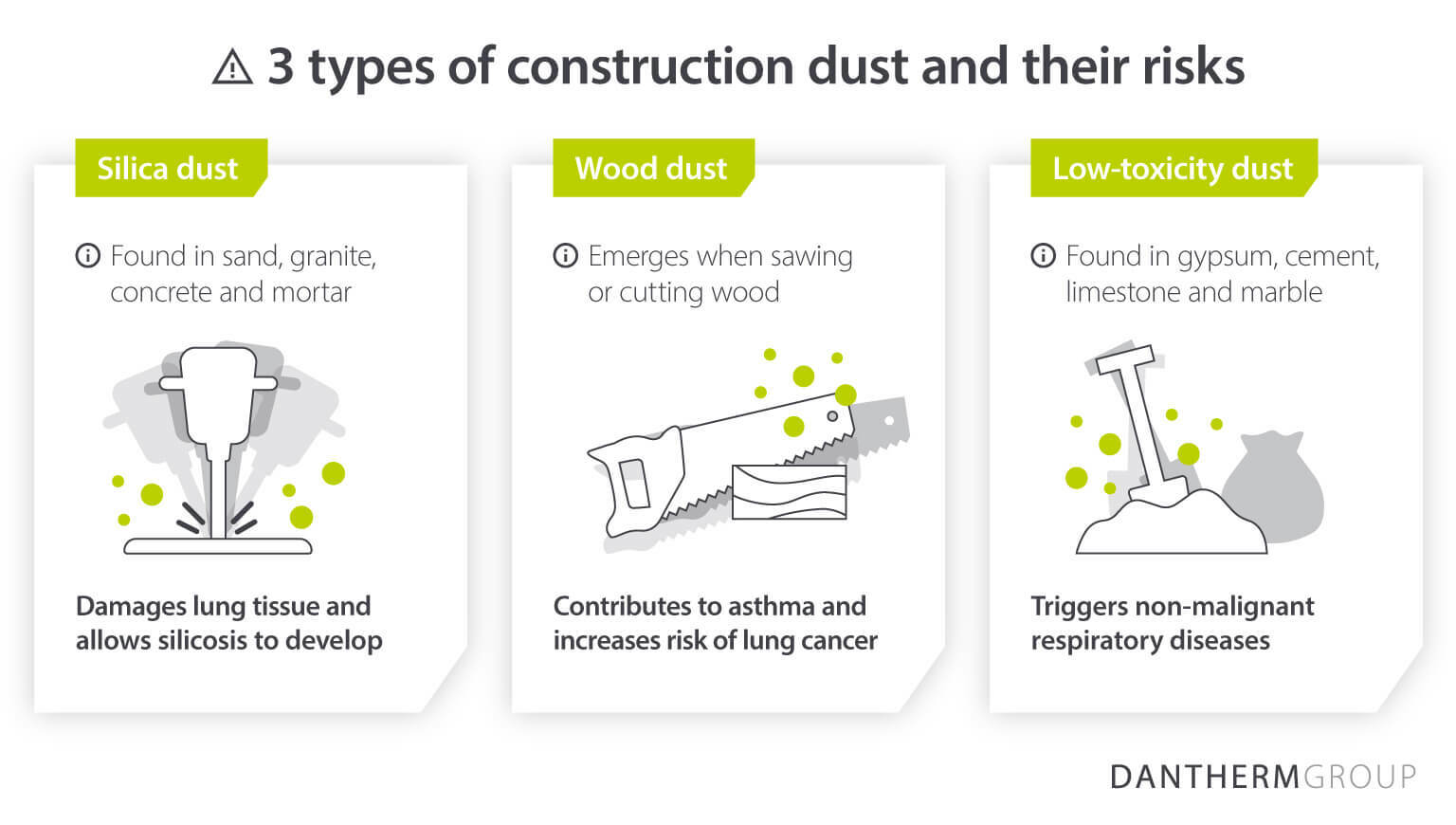

Construction dust is a dangerous substance that has the potential to damage the body, particularly the eyes and lungs, over time. It is present in three common types, each of which presents its own specific dangers:

What makes these types of particles even more dangerous is their microscopic size, making them virtually invisible to the naked eye and capable of staying airborne for up to 42 hours.

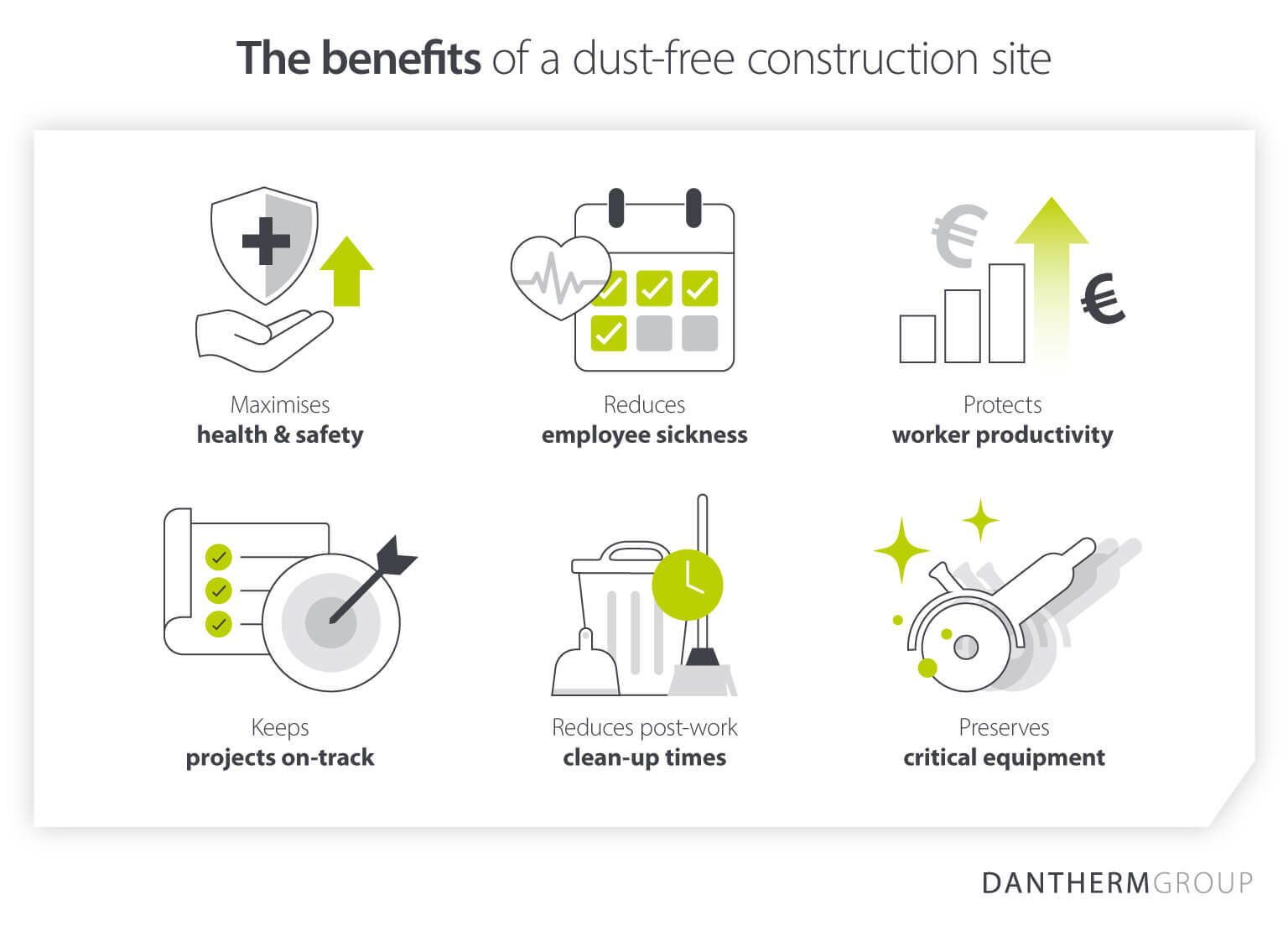

Germany estimates that 45,000 deaths can be attributed to fine dust exposure every year. Removing these harmful airborne pollutants remains a top priority, but employee safety alone is not the only reason to strive for dust-free construction sites:

Many regions have regulations that stipulate the maximum legal levels of construction dust on-site – exceeding these can result in fines or legal action

Poorly managed dust can spread to other parts of a building or to neighbouring property, affecting the health and wellbeing of local residents

Dust can also damage equipment and clog machines, requiring costly and time-consuming repairs

What are the challenges associated with removing construction dust?

Although building dust remains a real problem in the construction industry, removing these substances is easier said than done.

Dust is difficult to detect

Since microscopic construction dust particles are hard to see, it is challenging to identify where they have spread within a property, and consequently determine what level of dust control measures are needed in each area.

Particles are hard to capture

Capturing construction dust is also difficult due to its small size, which typically ranges between 0.1 and 0.3 microns in diameter. To effectively trap these tiny particles and improve air quality, it is essential to use specialist air filters and equipment.

Contaminants can be hard to reach

The layout of a construction site and the presence of structural obstacles such as walls, floors, and ceilings can make it harder and more time-consuming to remove dust from a space completely.

How can construction sites improve on-site air quality?

Creating a dust-free environment during construction projects benefits both the health of workers and the progress of building work in several key ways:

To realise these benefits and minimise the presence of construction particles on-site, it is critical to take preventative measures from the outset of a project.

Adequately prepare building materials off-site

Tweaking and adjusting building materials on-site is unavoidable. However, by doing as much preparation off the premises as possible, and pre-cutting materials to size, the amount of construction dust released indoors can be kept to a minimum.

Carefully consider the tools used

High-power tools are essential on practically every worksite, but they are not required for every task. By considering alternative tools for certain jobs – such as picking a block splitter over a saw, for example – fewer dust particles will need to be handled.

Prevent dust from getting airborne

When the emission of construction dust cannot be prevented, taking measures to prevent particles from getting into the air can minimise the health risk. Use water to wet down dust clouds and damp towels when cleaning to collect contaminants.

What equipment is required to create a dust-free worksite?

As well as taking proactive measures, it is also important to incorporate the right solutions to create a clean, breathable workspace.

Air cleaners

Air-cleaning machines such as dust air purifiers and scrubbers create healthy, dust-free working conditions, making them an essential component of any dust control strategy.

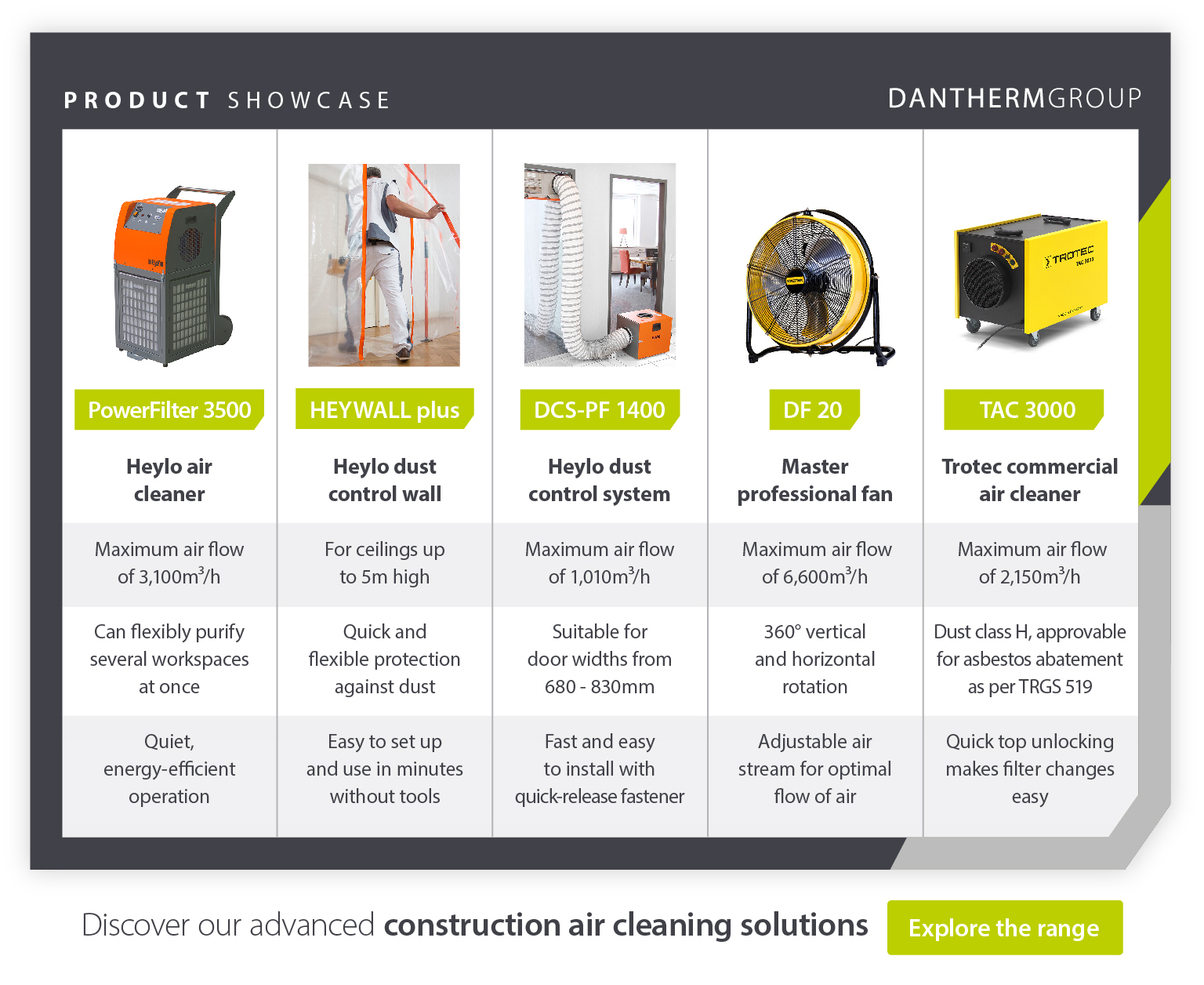

To prevent contaminants rising to unsafe levels, units such as the PowerFilter 3500 clean indoor air multiple times per hour, forcing contaminants through special filters that capture unwanted particles and purify indoor air.

Dust protection walls

Sometimes, renovation projects are carried out in a certain area of a building. Dust protection walls seal off work areas and prevent particles from infiltrating other spaces, minimising disruption and clean-up times.

Flexibly deployed where and whenever needed, solutions like the HEYWALL plus are easy to set up, creating an impenetrable partition that zones off workspaces and limits the spread of contaminants.

Dust control systems

Without any way for dust to escape, it can linger indoors for days. Dust control systems tackle this issue at the source, and constantly renew air in the areas where employees work, maximising staff health and productivity.

Units like the DCS-PF 1400 force polluted air through fine filters. Here, dust is captured as air is continually renewed several times every hour. At the same time, a negative pressure zone is created in the work area, preventing stray particles escaping.

Fans for construction dust

Fans and blowers can create a negative vacuum in the workspace, preventing contaminated air from leaving the site, while also permitting a comfortable flow of air indoors.

For example, the DF 20 is a professional construction fan that operates efficiently, able to meet the rugged demands of construction sites.

How often should construction dust be removed?

The frequency that construction dust has to be removed depends on the volume of contaminants being produced, as well as the specific dust control measures in place.

As a guideline, these contaminants should be removed on a daily basis to prevent toxic particles from accumulating to unsafe levels.

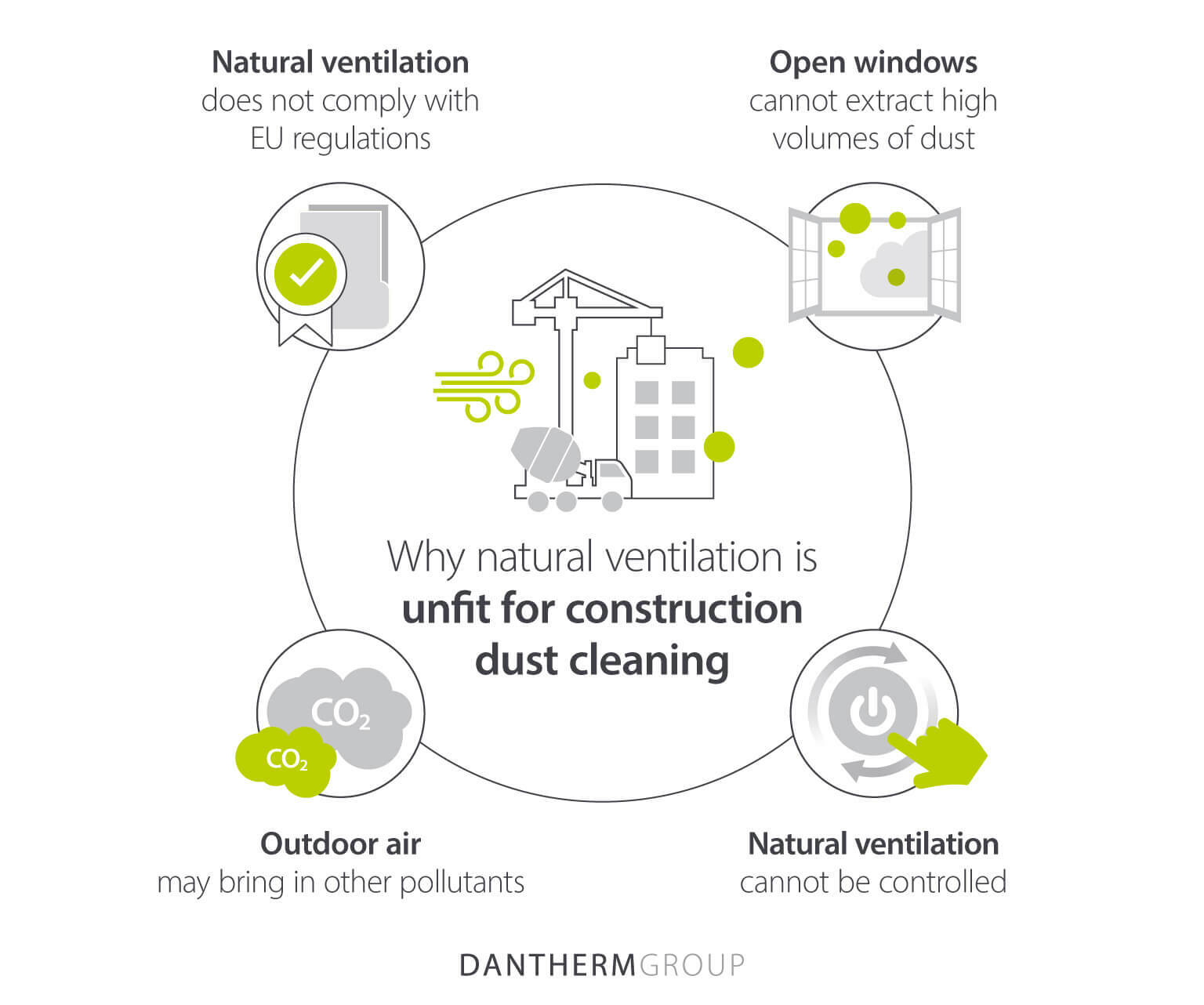

Is natural ventilation suitable for construction dust cleaning?

Natural ventilation is not a reliable method for construction dust removal due to its unpredictable nature. This can result in inconsistent and incomplete dust cleaning, as well as a variety of other drawbacks.

Choose the right equipment for your construction project

Employing specialist equipment that captures dust is crucial when conducting virtually any type of professional home renovation or construction project.

But, no two projects will have identical demands. Depending on the size of a workspace and the type of construction dust emitted, the right type and size of equipment will vary.

To unlock the best performance and the greatest savings, it is important to speak to experts who can advise you on your ideal solution.

From practical air scrubbers to easy-to-use dust protection walls, Dantherm Group is Europe’s foremost supplier of construction dust control technology. Our air cleaning solutions are trusted worldwide and are actively used in countless projects.

It is not just our efficient, sustainable and durable systems that make us the provider of choice. With expertise dating back to 1954, and highly skilled technicians that help you unlock your solution’s full potential, you can always rest assured your employees and investments are protected.

Discover the best way to clean up dust during construction work – get in touch with our team for more information.

Related products

Featured insights

Discover the health and safety benefits that dust control systems can deliver to construction sites.

Learn how to best keep people on building sites safe from the dangers posed by dust.

Creating healthy, clean air on construction sites.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.