Adsorption or condensation? Choosing the right dehumidifier for your needs

- Home

- Insights

- Humidity control and drying insights

- Adsorption or condensation? Choosing the right dehumidifier for your needs

Unless you just heat and ventilate with huge uncontrolled energy consumption, there are two choices when it comes to dehumidification in buildings and commercial spaces: adsorption and condensation. Either one can offer the ideal solution, but to determine the most suitable system for you will depend on how well you understand your environment and its requirements.

The choice you make will dictate the efficiency and cost-effectiveness of maintaining humidity within your building. In this article, we explain the differences between adsorption dehumidifiers and condensation dehumidifiers, the applications most suited to each, and why Dantherm Group has become such a renowned source of expertise across Europe.

What is dehumidification?

While this may seem like going back to basics, choosing the right system relies upon an understanding of the key scientific principles that dictate how moisture is removed from the air.

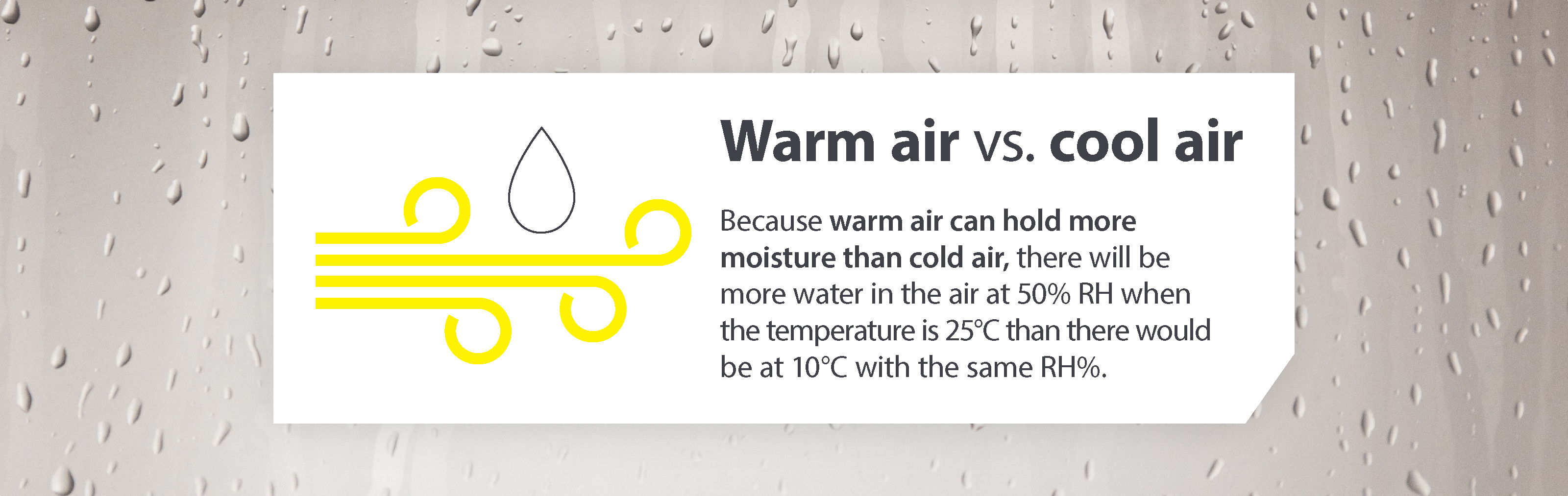

At the centre is relative humidity (RH). This is a unit (represented as a percentage) that tells us the amount of water vapour held in the air in relation to the amount of water vapour that the air can hold at its current temperature.

It’s the reason that temperature is such a defining factor in the efficiency of a dehumidifier and the cost-effectiveness of your chosen solution.

When the temperature falls, the relative humidity will increase, indicating that the air has less capacity to hold moisture. Eventually, the environment will reach 100%RH or the ‘dew point’ – the state at which the air can no longer hold water and begins to release it in the form of condensation.

Inside buildings, this is most common when warm, water-saturated air comes into contact with cold surfaces like metal fittings or single-glazed windows.

As a rule of thumb, it is important to maintain relative humidity below 60%RH to prevent rust, mould and other effects of excess humidity causing extensive damage to buildings. At the same time, it’s important to keep an RH level between 50% and 60% to maintain healthy and comfortable conditions for people inside the buildings.

What’s the difference between condense and adsorption dehumidification?

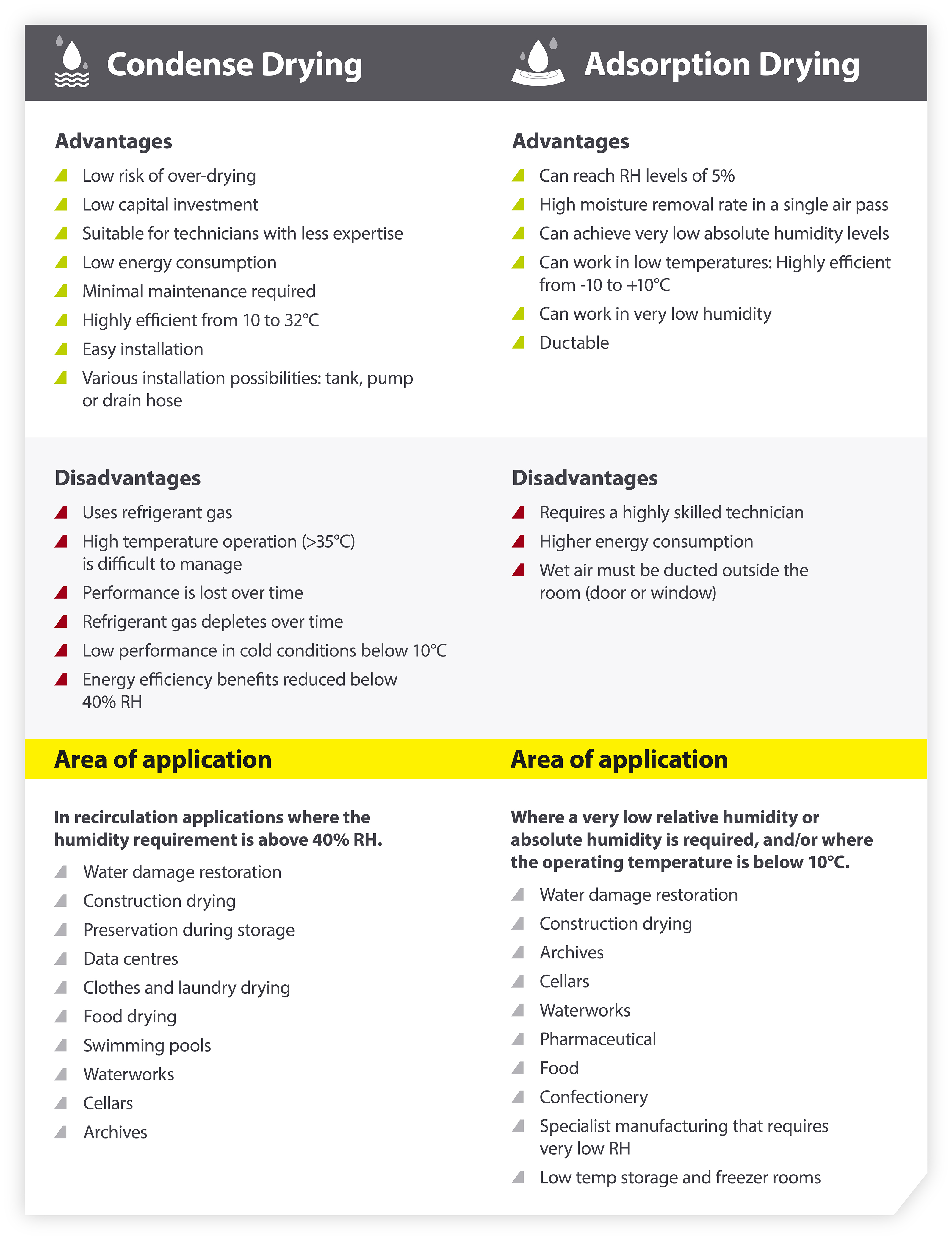

While both solutions remove moisture from the air, different processes affect their drying performance and energy usage in different environments.

Condense drying

Also known as refrigerant dehumidification, a condense unit draws moisture-laden air (humid air) into a dehumidifier and across a refrigerated coil. The air is rapidly cooled below its dew point, condensing the water vapour and recovering its latent heat energy for re-use. The cooled air is then passed across the condenser where it is reheated and returned to the room as warm air at the required lower humidity.

Adsorption drying

Often referred to as desiccant dehumidification, an adsorption dehumidifier brings the air to be dehumidified (process air) through a slowly rotating silica gel rotor. The desiccant material attracts the moisture to its surface, removing it from the air stream (dry air). Behind the rotor, the air flow is split: a part of it is discharged as dry air, the other part is used to regenerate the rotor. This (wet) air must then be exhausted to the atmosphere using a duct. Slowly rotating the rotor through both air-streams creates a continuous dehumidification process.

Which is the right solution for you?

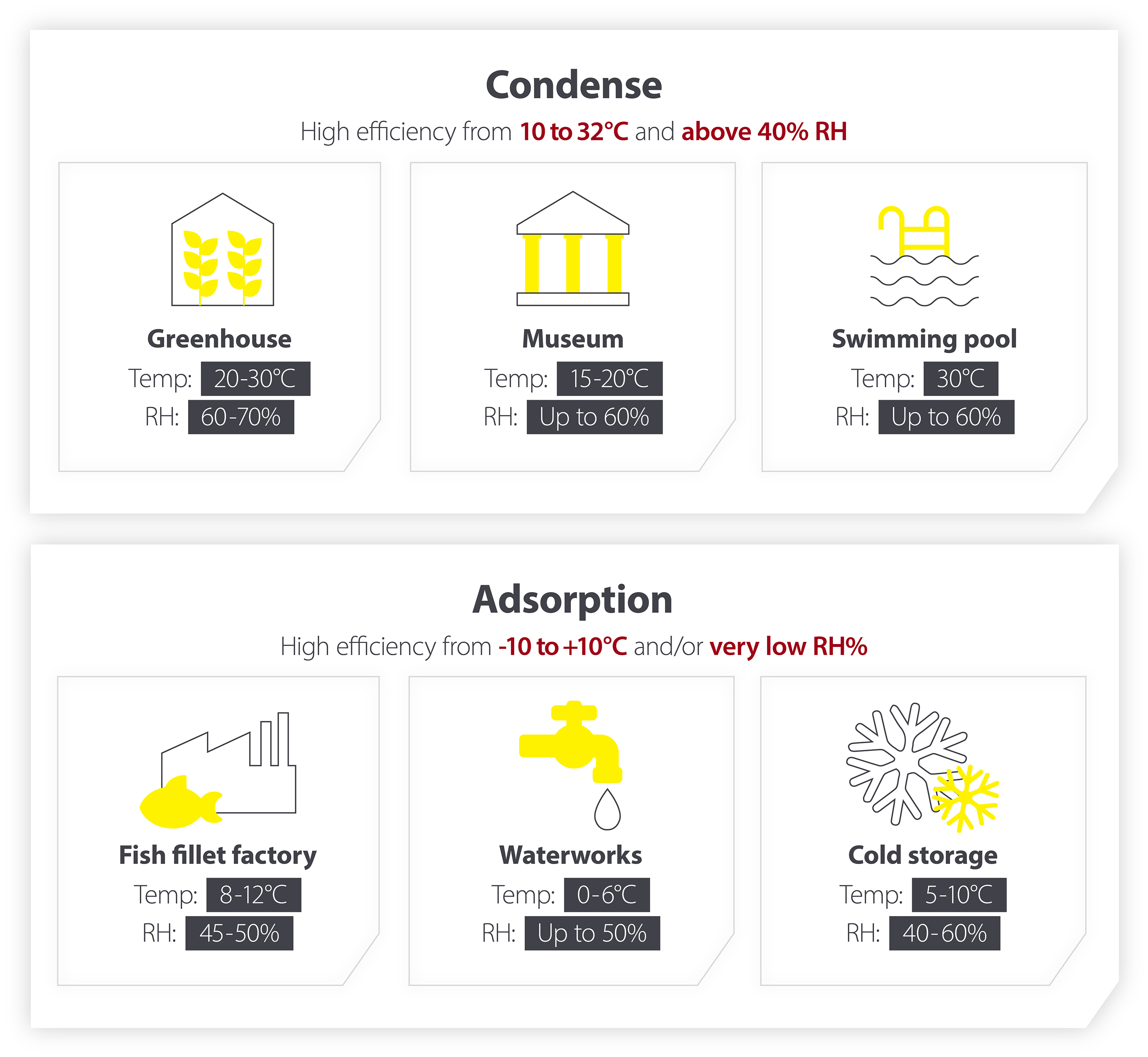

The infographic above should give you a clear overview of the differences between the two types of system. Determining the most appropriate unit for your environment is centred on creating the most ideal conditions while minimising costs. In other words, balancing what’s technically possible with what’s sustainable.

This takes us back to the relationship between temperature and relative humidity.

At higher temperatures, condense technology will usually be more energy efficient. In humid environments like a swimming pool, for example, the energy consumption using an adsorption solution can be 3-4 times higher when compared to a condense solution. That’s a lot of wasted money and a great cost to the environment.

However, condense dehumidifiers and drying units have limitations under 8°C and 40%RH, which makes them less suited to more controlled environments. In laboratories, for example, an RH level lower than 30% is often required, and in freezer rooms and cold storage facilities, temperatures are usually around -18°C. In both these cases, an adsorption solution is much more efficient in terms of both cost and performance.

That’s why we always start with the temperature and the required RH level. Below are some common examples of how temperature and relative humidity can determine your choice of technology:

Why you should speak to an expert before making your decision

It’s very rare that there is only ever one correct solution to dehumidify an environment. As the fish fillet factory example above shows, there are applications which deviate from the guidance with temperature and RH. The examples above are therefore not necessarily definitive and specialists should be consulted in every case. Even after thorough research, you may find yourself faced with a choice of several different units which, on paper, all seem appropriate. To select the best, it's important to work with an expert to understand the specific needs of your environment.

Making the choice between desiccant and condense is not the only deciding factor of your solution. Other important considerations include:

Fresh air

Part of a carefully controlled environment includes the circulation of clean fresh air throughout the building.People

It’s the responsibility of a building or property owner to ensure a safe and comfortable environment for staff, customers and visitors.Construction

The age, location and materials of a building will affect the way it reacts to temperature and humidity. For example, older buildings with less insulation and low natural lighting will be more susceptible to mould and damp due to fast drops in temperature.Items in storage

Storage facilities could be used to house food products, classic cars or delicate archives – all of which are highly reactive to changes in temperature and humidity.Times of year

Humidity levels change naturally with the seasons. In locations with fluctuating climates, your dehumidification system needs to be effective all year round.Investment value versus operating costs

When both technologies can be used, the decision maker is often tempted to choose the solution with lowest investment. However, a Life Cycle Cost (LCC) analysis proves that for solutions with significantly lower operating costs, a higher investment is the most economical choice.

Benefit from expertise in both solutions

Because Dantherm Group develops condense and adsorption solutions, our sales team has no incentive to promote one methodology over another. This puts them in the best position to work with you to understand your business before recommending the most suitable unit from our large range of commercial and industrial dehumidifiers.

With five decades of understanding across various sectors, as well as the benefits and limitations of both types of solution, we can provide the best system in terms of suitability, energy efficiency and drying performance.

To find out more, and discover the best condense or desiccant system for your building, get in touch with our team via the form below.

Related products

Featured insights

Top tips for drying out buildings

What makes waterworks susceptible to condensation?

Maintaining the right humidity levels in waterworks

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.