Eco-friendly BioFuel heaters: An innovation from Master

- Home

- Insights

- Heating insights

- Eco-friendly BioFuel heaters: An innovation from Master

In line with our commitment to contribute to a more sustainable world, while ensuring the same high product quality and customer experience, our Master heater range is compatible with sustainably sourced BioFuel HVO 100.

Since 2022, Master has been manufacturing heaters compatible with BioFuel HVO 100 and diesel. Since 2023, every heater manufactured by Master is BioFuel HVO 100 compatible, allowing our customers to choose the fuel they like.

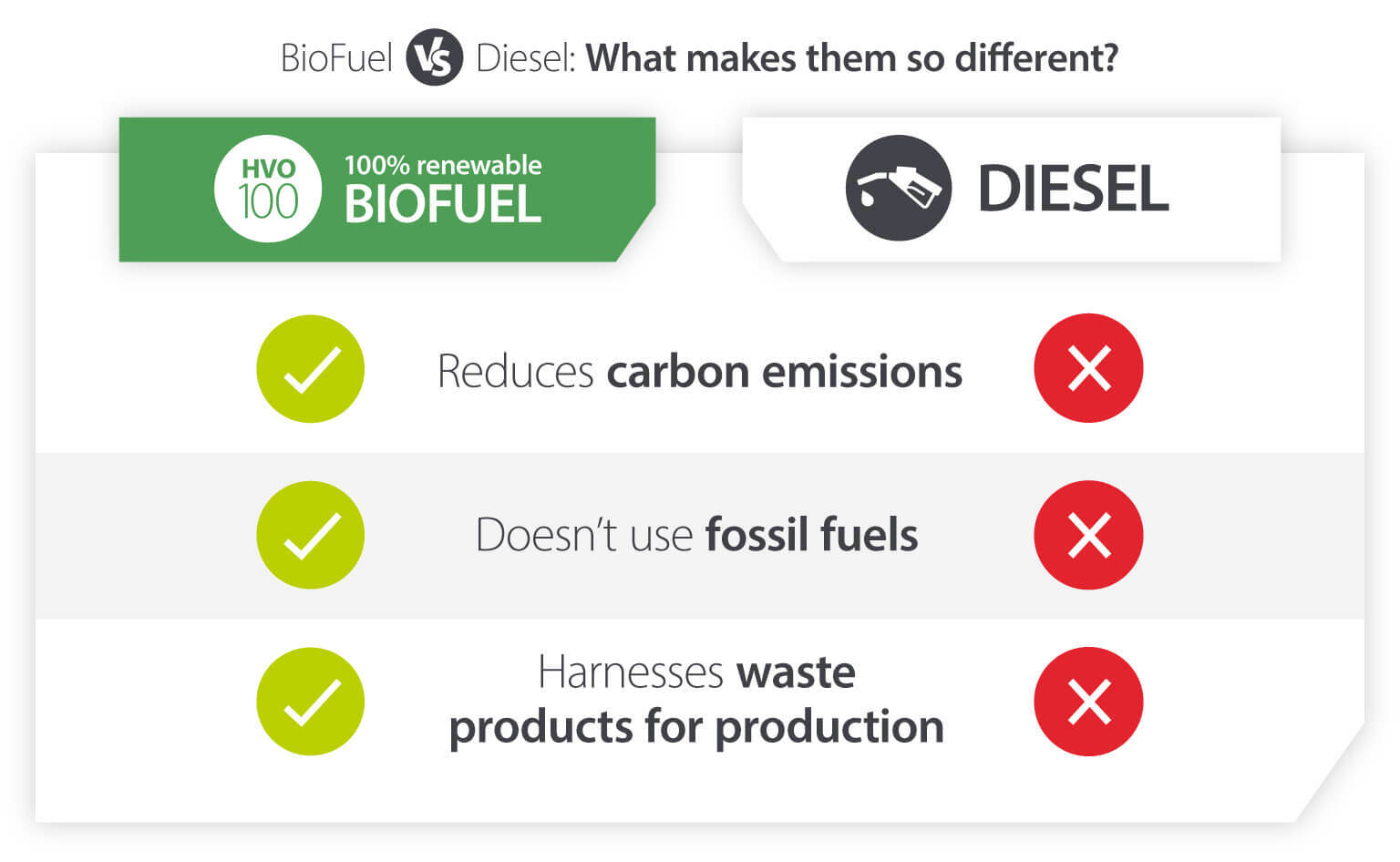

Most existing portable fuel heaters currently use diesel only. But as a company, we recognise that this is damaging our planet as diesel delivers an avoidable excess of CO₂ into the air.

There are now multiple BioFuels available that use biomass as a source of renewable energy. We have carefully reviewed and selected the most ecological fuel HVO 100 to ensure that our new commitment is the most impactful it can possibly be. This fuel is made from 100% biological material, and it is obtained through a process of hydrogenation.

Some countries have already taken a strong decision to embrace BioFuel, especially after the announcement at COP26. The UK has already ordered that after March 2022, only HVO 100 will be allowed for use on construction sites. Norway and Sweden are also heading in the same direction. Many other countries are expected to follow suit.

What’s wrong with regular diesel?

Diesel is an extremely stable fuel – it’s not flammable and is safe in many environments – so it has long been the go-to choice for fuel to heat. But it’s made from fossil fuels and its use is dramatically risking the environment, burning CO₂ into the atmosphere.

Many cars are going electric or hybrid to combat this issue, but we can’t use electricity alone for every product that requires power.

That’s why we decided to align our commercial heater range with a new generation of eco-friendly fuels that transform agricultural waste into BioFuel HVO 100.

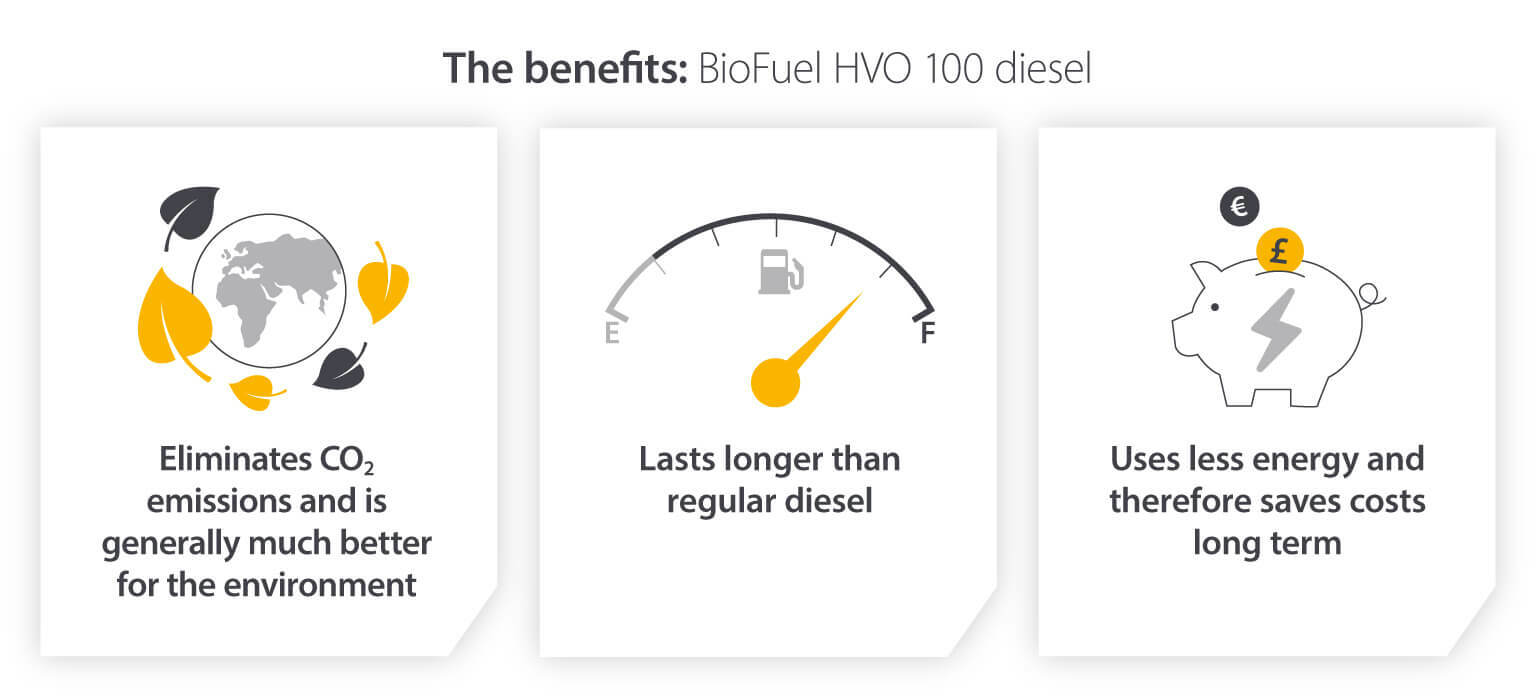

What are the benefits of BioFuel?

The biggest positive of BioFuel is that it marks a significant move in helping the environment and will let us all take a giant leap towards embracing more sustainable fuels. The biodiesel alternative has much lower net CO₂ greenhouse gas emissions – and can significantly reduce your carbon footprint.

While the cost of producing BioFuel is around 10% more than regular diesel, this is probably because adoption is still gradual, and processes haven’t been optimised to be as efficient as they can be.

With more and more governments keen to pursue BioFuel as an alternative, and the long-term usage and benefits being much higher, we are likely to see the processes behind HVO become more cost-efficient quickly, as leaders introduce incentives to encourage others to produce these fuels, widen the market and lower costs.

At the beginning of the journey, all existing Master heaters were adapted to accept BioFuel (changes are due to allow the best combustions), and any new ones would come with BioFuel compatibility as standard.

What does our commitment to the environment look like longer term?

The change towards bringing Master heaters to accept BioFuel is a step in the right direction – but we’ve still got a lot of work left to do.

As a company, we are proud to be highly engaged in environmentalism. We’re working on a number of endeavours that are targeting the CO₂ impact of our factories and moving away from diesel on a much bigger scale.

We build products made to last – we source and use only the best components and materials.

We ensure our heaters last longer – all our spare parts and accessories are available for at least 10 years from product launch to encourage maintenance of the same products and prevent unnecessary re-purchases.

We trust our quality – we offer a 3-year limited warranty on all Master products as standard.

We package responsibly – our packaging allows for optimal space utilisation in trucks and containers so we reduce our transportation footprint. Our materials can be easily recycled – cardboard, paper and styropor.

We help to avoid overheating and overspending – our heaters can be controlled via a remote thermostat, so you can stay in control at all times.

BioFuel is here. Are you ready to embrace the change?

Whether you are considering adapting your existing heaters or thinking about your company’s longer-term commitment to sustainability, speak to our expert team for an informative conversation about the technology that can help to get you there.

Reach out to us using the form below and we will be in touch.

Related products

Featured insights

Flexible heating for animal keeping and drying and storage of produce

Why you need more than just any old portable heater

Why heaters offer a cleaner, quicker solution than chemicals

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.